Low voltage wiring, Heater – Goldline LOGIC PL-P-4 User Manual

Page 16

Low Voltage Wiring

Valve Actuators

The Pro Logic can control up to three automatic valve actuators. Two of the valve outputs are dedicated to the pool/

spa suction (Valve2) and return (Valve1) valves. Valve3 is for general purpose use (solar, water feature, in-floor

cleaner, etc.).

For installations with solar heating, Goldline offers the AQ-SOL-KIT-xx solar kit that contains a valve, actuator, and

extra temperature sensor. The “xx” indicates the valve type from the 3 choices below:

-1P

1.5” Positive Seal

-2P

2” Positive Seal

The Pro Logic is compatible with standard valve actuators manufactured by Hayward, Pentair/Compool, and Jandy.

See diagram on page 10 for the location of valve connectors.

Heater Control

The Pro Logic provides a set of low voltage dry contacts that can be connected to most gas heaters or heat pumps with

24V control circuits. Refer to the diagram below for a generic connection. The manuals supplied with most heaters

also include specific wiring instructions for connecting the heater to an external control (usually identified as “2-wire”

remote control). For millivolt or line voltage heaters, contact Goldline Tech support, 908-355-7995. Refer to the

diagrams and the information on the following pages for more details on the connection to several popular heaters.

Generic Heaters

1. Wire heater to 120/240V power source per the instructions in the heater manual. The Pro Logic does NOT

control the power going to the heater.

2. Wire the Pro Logic dry contact heater output per the diagram below. Many internal parts of the heater can get very

hot--see the heater manufacturer’s recommendations on the minimum temperature rating for wires. If no guidance

is given, use 105°C rated wire.

3. Set any ON/OFF switch on the heater to ON.

4. Set the thermostat(s) on the heater to the maximum (hottest) setting.

Ignition/Valve

Heater

Kill Switch

Thermostat

13

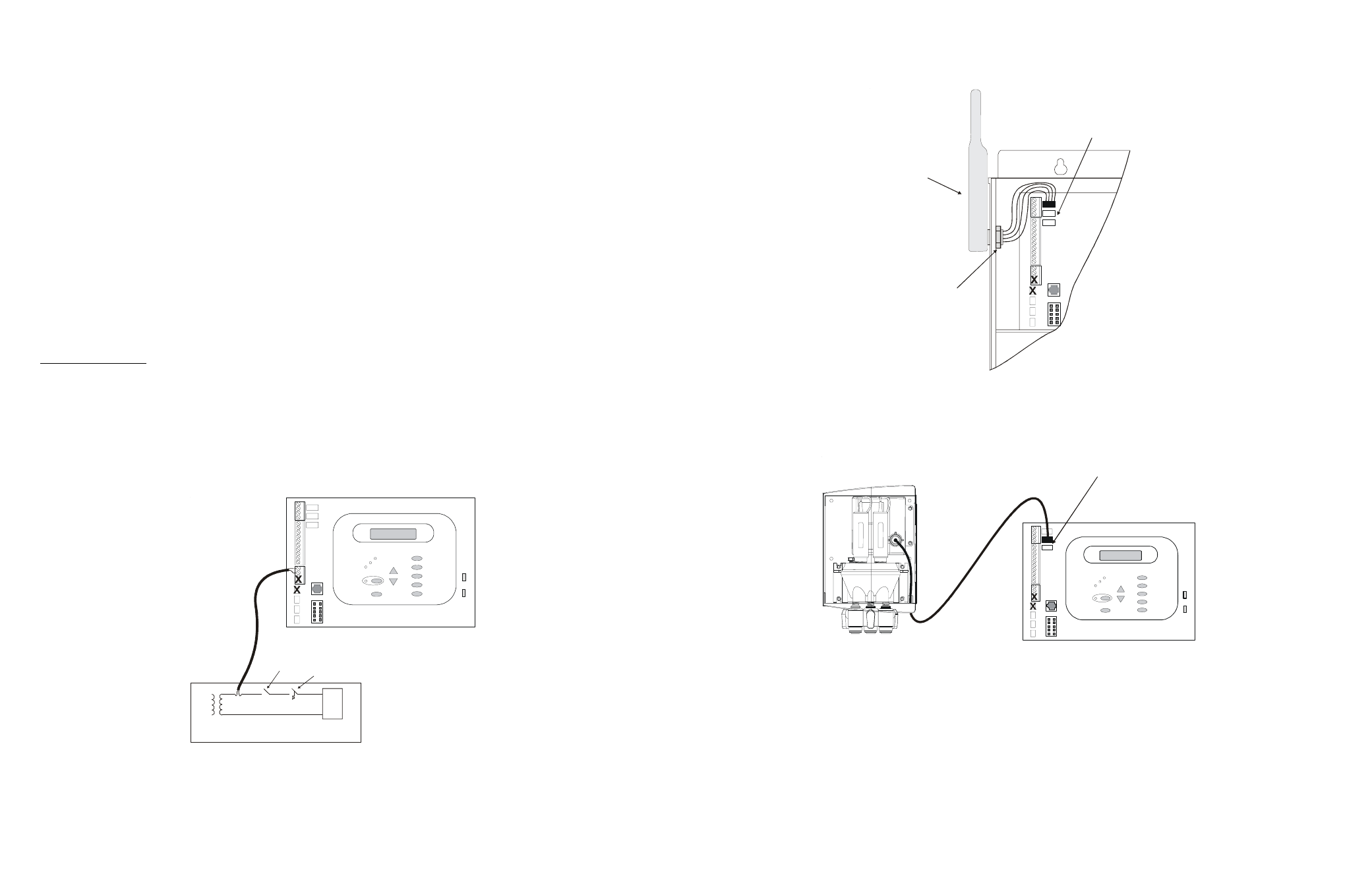

Base Station

Plug in the pigtail connector from the wireless base station into the “wireless” connector on the main PCB

in the Pro Logic control unit.

Base Station

(AQL2-BASE-RF)

Tighten nut

Pro Logic

Main PCB

Connector for

Base Station

AQL-CHEM ORP and pH Sensing Kit

Plug in the connector from the AQL-CHEM into one of the “COMM” connectors on the main PCB in the

Pro Logic control unit as shown below.

Connector for

AQL-CHEM

Flow Switch

Only applicable if the chlorinator function is enabled. The flow switch cable plugs into the Pro Logic

Control Center at the position shown in the diagram on page 10. Ensure that the connector catch “snaps”

in order to provide a reliable connection.

Turbo Cell

Only applicable if the chlorinator function is enabled. The Turbo Cell should be plugged in after the

Pro Logic cover panel is put back in place. Refer to page 10 for the location of the connector.

18