Sanding/finishing – Grizzly Variable Speed Wood G8690 User Manual

Page 20

g8690 variable speed Wood lathe

-18-

2. locate and mark the center of both the work-

piece and the backing block.

3. drill a

1

⁄

4

" diameter hole through the center of

the backing block.

4. glue the center of the backing block to the

center of the workpiece (look through the

drilled hole to line up centers), clamp the

backing block to the workpiece, and wait for

the glue to cure according to the manufactur-

er’s recommendation.

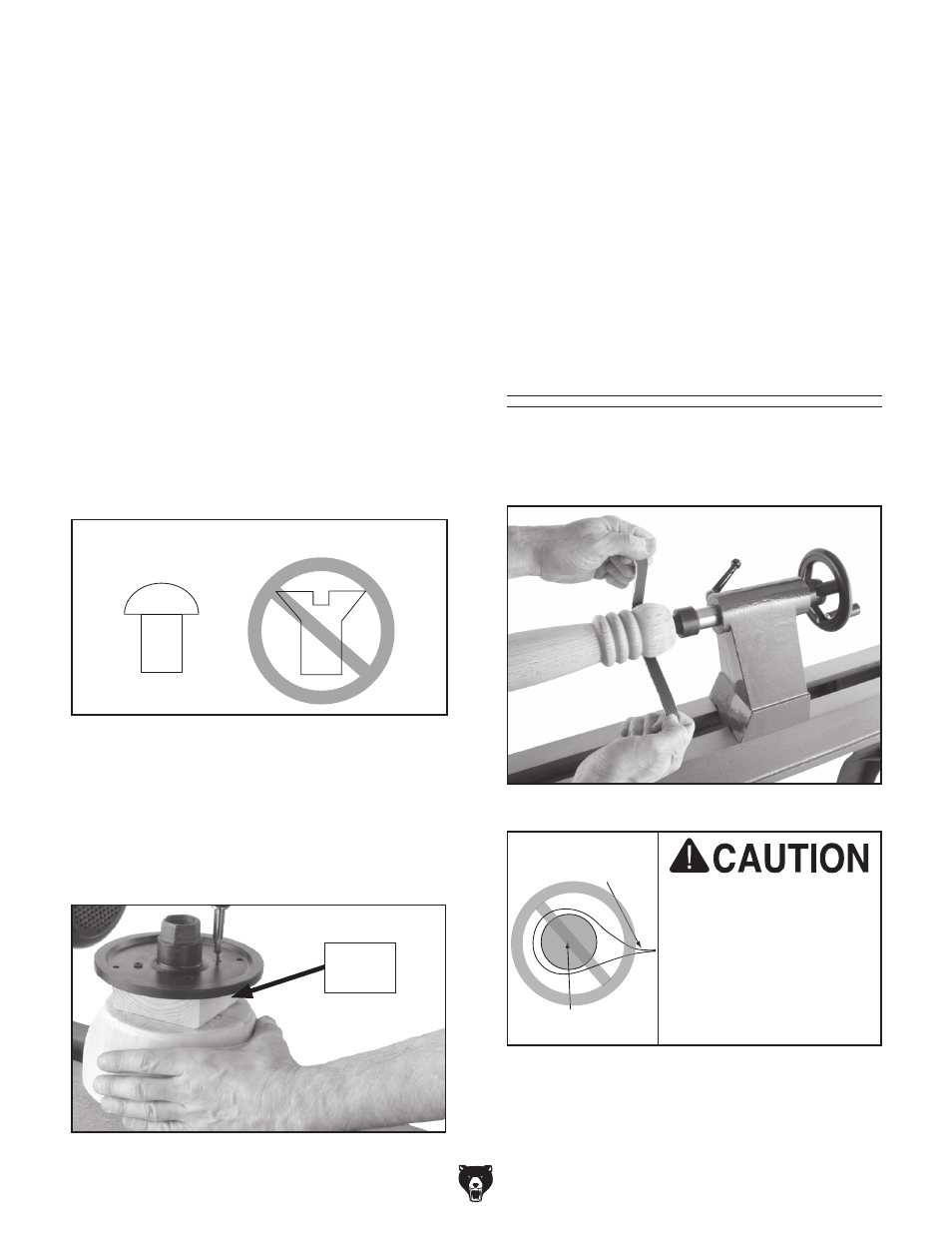

NOticE: Only use tap screws or wood screws

with non-tapered heads (

Figure 18) to attach the

faceplate to the workpiece. Do NOT use drywall

screws or screws with tapered heads because

these can split the faceplate, or the screws may

snap off during operation.

figure 19. example of backing block mounting.

Backing

Block

to mount your workpiece to a backing block:

1. make the backing block (figure 19) from

a piece of scrap wood that is flat on both

sides.

769 figure 18. Correct and incorrect screw types for mounting faceplate to workpiece. after turning, the workpiece can be sanded, as figure 20, and finished (in the same manner) before removing it from the lathe. sanding/finishing figure 20. typical sanding operation. Whenever sanding or finishing, move the tool rest HVcYeVeZg Ldg`e^ZXZ wrapping the sandpa- per completely around the workpiece will pull your hands into the mov- ing workpiece and may cause injury. Never wrap sandpaper completely around the workpiece! to mount your workpiece to the faceplate: 1. Find the center of your workpiece in the same manner as when spindle turning. 2. Cut off the corners of the workpiece. 3. Center the faceplate on the workpiece and attach it through the faceplate holes with figure 18. 4. thread the faceplate onto the headstock spindle and tighten securely.

shown in

holder out of the way to increase personal safety

and gain adequate working room.

non-tapered head wood screws as shown in