Tool rest, Faceplate turning – Grizzly Variable Speed Wood G8690 User Manual

Page 19

g8690 variable speed Wood lathe

-17-

tool rest

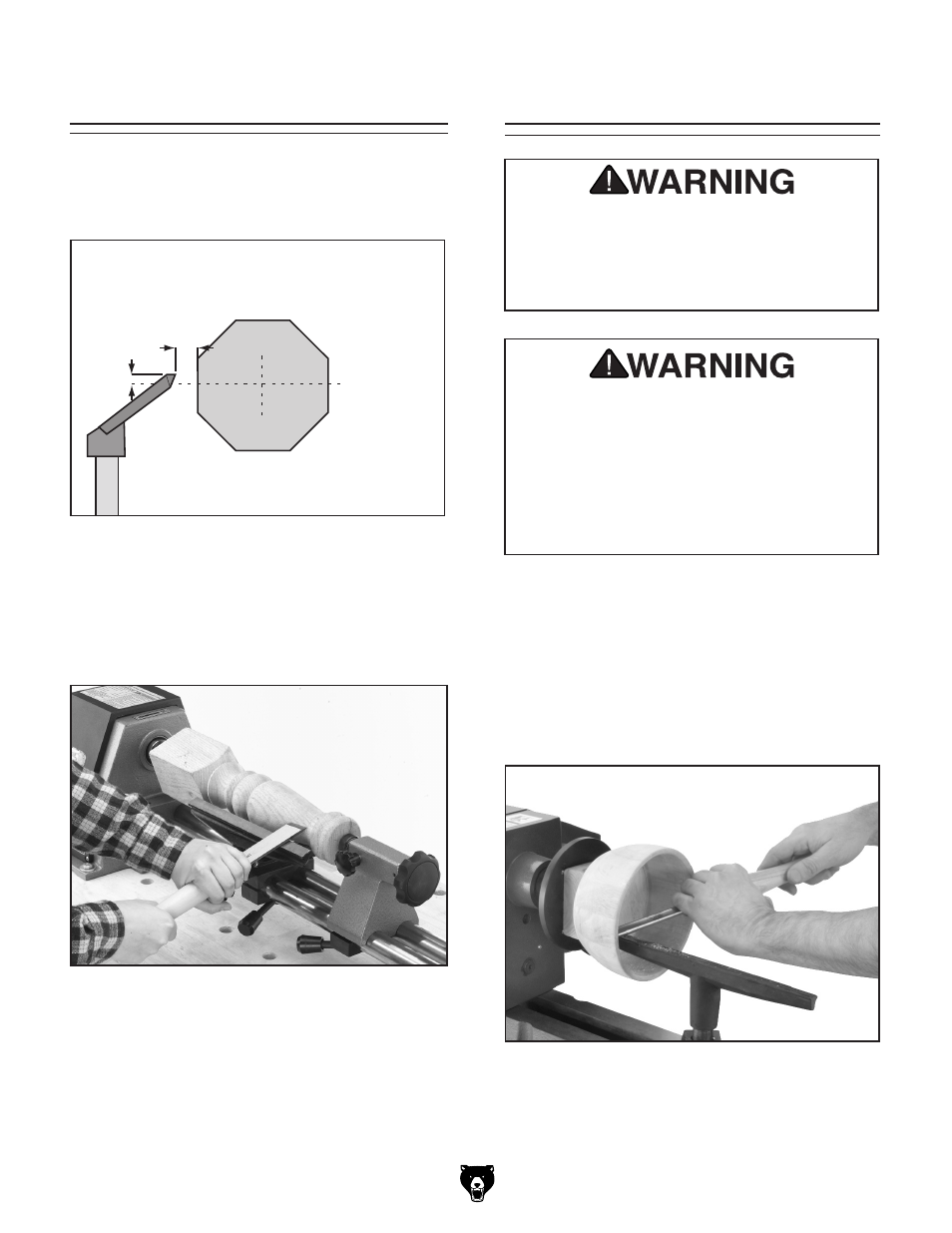

test by hand-turning the workpiece before turning

the lathe on. ensure that the lathe chisel is fully

supported by the tool rest. support the lathe chisel

on the tool rest with one hand, while the other

hand controls the chisel. see

figure 16.

figure 16. Correct hand placement for opera-

tion.

position the tool rest approximately

1

⁄

4

" away from

the workpiece and approximately

1

⁄

8

" above the

center line, as shown in

figure 15.

Ldg`e^ZXZ

8ZciZgA^cZ

9^hiVcXZh

IddaGZhi

&$-

&$)

figure 15. tool rest position.

Faceplate turning (

figure 17) is when a workpiece

is mounted to the faceplate, which is mounted to

the headstock spindle. this type of turning is usu-

ally done with open-faced workpieces like bowls.

if screws cannot be placed in the workpiece, then

a backing block can be glued to the workpiece

and attached to the faceplate with screws.

figure 17. typical faceplate turning operation.

faceplate turning

the contact area between the workpiece

and the faceplate must be flush with one

another. failure to do this could result in

the faceplate distorting or breaking, causing

injury or death.

the joints of glued-up workpieces should be

high quality to prevent them from breaking

under the extreme forces of lathe turning.

consult in-depth trade manuals and instruc-

tional books for correct techniques when

gluing up a workpiece from multiple pieces.

if a joint fails during a lathe turning opera-

tion, serious injury or death could occur.