Test 8- check sensing leads / power windings, Test 9- check brush leads – Guardian Technologies 4270 User Manual

Page 43

Section 7

DIAGNOSTIC TESTS

Page 41

TEST 8- CHECK SENSING LEADS / POWER

WINDINGS

DISCUSSION:

The Voltage Regulator “regulates” excitation current

flow to the Rotor by electronically comparing sensing

voltage to a pre-set reference voltage. The sensing

voltage is delivered to the Voltage Regulator via

Wires 11 and 22.

If an open circuit exists in sensing leads 11S or 22S,

the normal reaction of an unprotected Regulator

would be to increase the excitation current to the

Rotor in an effort to increase the actual AC output

voltage. This would result in a “full field” condition and

an extremely high AC output voltage.

To protect the system against such a high AC output

voltage, the Voltage Regulator will shut down if sens-

ing voltage signals are lost.

If the regulator shuts down, the generator's AC output

voltage will decrease to a value that is equal to the

Rotor's residual magnetism (about 5-12 VAC).

PROCEDURE:

Gain access to the generator control panel interior.

Test the Stator power windings, as follows:

1. From main breaker, disconnect Wires 11 and 44.

2. Also disconnect Wires 22 and 33 from the ground terminal.

3. Disconnect Wires 11 and 22 ( sensing leads) from the Voltage

Regulator.

4. Set a VOM to its “Rx1” scale and zero the meter.

5. Connect the meter test leads across Stator leads 11 and 22.

Normal power winding resistance should be read.

6. Connect the meter test leads across Stator leads 33 and 44.

Normal power winding resistance should be read.

7. Connect the meter test leads across Stator sensing leads 11

and 22. Normal Power Winding resistance should be read.

AC POWER WINDING RESISTANCE

*

QP75D

ACROSS WIRES:

OHMS

11 & 22

0.159W

33 & 44

0.184W

* Resistance values in ohms at 20° C. (68° F.). Actual readings

may vary depending on ambient temperature. A tolerance of

plus or minus 5% is allowed.

8. Now, set the VOM to its “Rx1 K” or “Rx10,000” scale and zero

the meter.

9. Connect the meter test leads across Stator lead 11 and

ground. “Infinity” should be read.

10. Connect the meter test leads across Stator lead 33 and

ground. The reading should be “Infinity”.

11. Connect the meter test leads across Stator leads Wire 11 and

Wire 33. The reading should be “Infinity”.

12. Connect the meter test leads across Stator leads Wire 11 and

Wire 66. The reading should be “Infinity”.

13. Connect the meter test leads across Stator leads Wire 33 and

Wire 66. The reading should be “Infinity”.

14. Connect the meter test leads across Stator leads Wire 11 and

Wire 2. The reading should be “Infinity”.

15. Connect the meter test leads across Stator leads Wire 33 and

Wire 2. The reading should be “Infinity”.

RESULTS:

1. If the Stator passes all steps except Step 7, repair, re-connect

or replace Sensing leads 11 and 22.

2. Replace the Stator if it’s power windings fail the test. (Note

Result No. 1).

3. If the Power Windings test good, perform the “Insulation

Resistance Test” on Page 13.

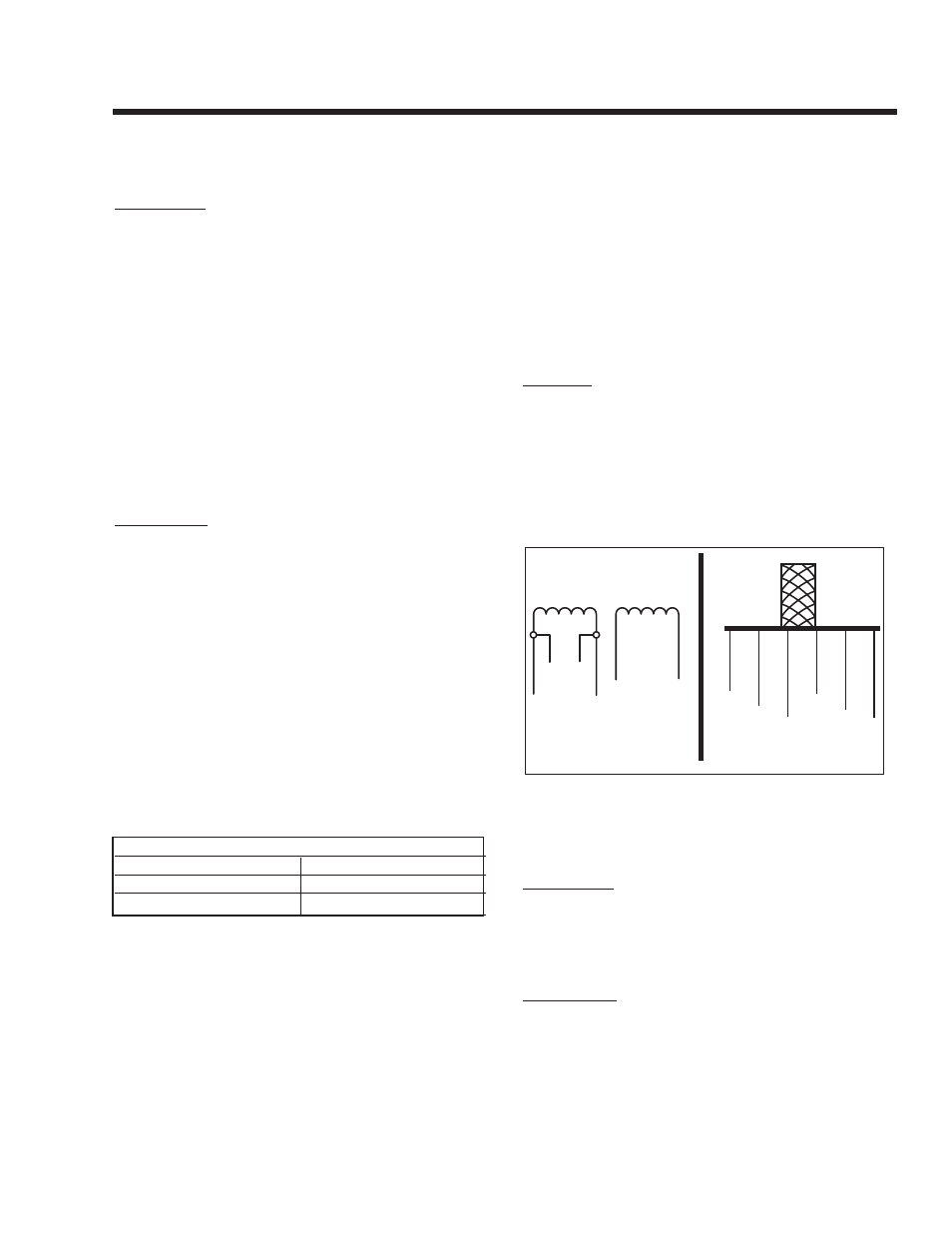

Figure 7-5. – Stator Power Winding Leads

TEST 9- CHECK BRUSH LEADS

DISCUSSION:

In Test 4, if application of battery voltage to the Rotor

did NOT result in an output of about one-half rated

voltage, the brush leads could be one possible cause

of the problem. This test will check Wires 4 and 1 for

an open circuit condition.

PROCEDURE:

1. Set a VOM to its “Rx1” scale and zero the meter.

2. Disconnect Wire 4 from the Voltage Regulator and from the

Rotor brush terminal.

3. Connect the VOM test leads across each end of the wire. The

meter should read “Continuity”.

4. Disconnect Wire 1 from the Rotor Brush Terminal. Connect

A. Schematic

B. Pictorial

33

33

44

44

11

11

11

22

11

22

22

22