Guardian Technologies 4270 User Manual

Page 14

Section 3

INSULATION RESISTANCE TESTS

EFFECTS OF DIRT AND MOISTURE

Moisture and dirt are harmful to the continued good

operation of any generator set.

If moisture is allowed to remain in contact with the

Stator and Rotor windings, some of the moisture will

be retained in voids and cracks of the winding insula-

tion. This will result in a reduced insulation resistance

and, eventually, the unit's AC output will be affected.

Insulation used in the generator is moisture resistant.

However, prolonged exposure to moisture will gradu-

ally reduce the resistance of the winding insulation.

Dirt can enhance the problem, since it tends to hold

moisture into contact with the windings. Salt, as from

sea air, contributes to the problem since salt can

absorb moisture from the air. When salt and moisture

combine, they make a good electrical conductor.

Due to the detrimental affects of dirt and moisture, the

generator should be kept as clean and as dry as pos-

sible. Rotor and Stator windings should be tested

periodically with an insulation resistance tester (such

as a megohmmeter or hi-pot tester).

If the insulation resistance is excessively low, drying

may be required to remove accumulated moisture.

After drying, perform a second insulation resistance

test. If resistance is still low after drying, replacement

of the defective Rotor or Stator may be required.

INSULATION RESISTANCE TESTERS

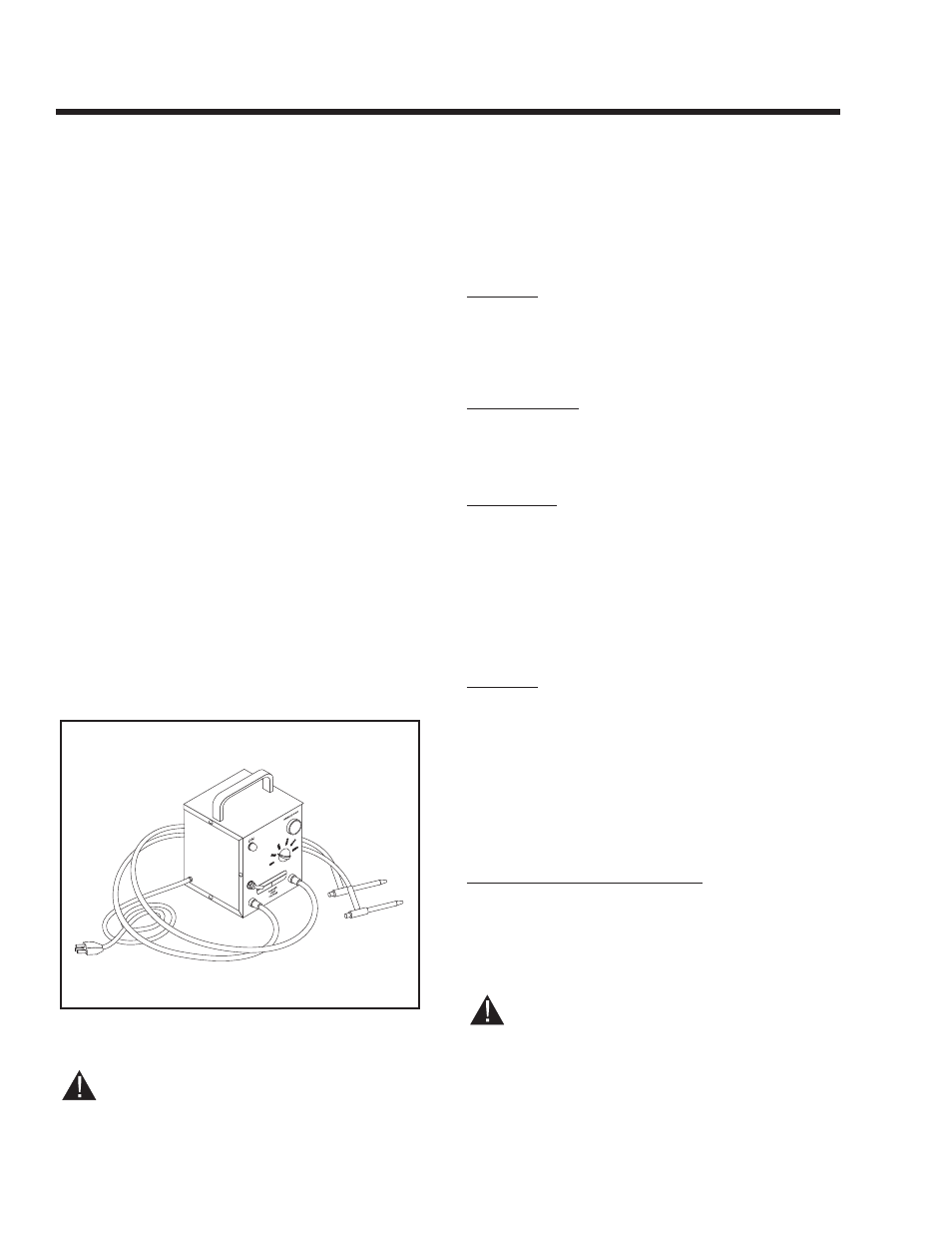

Figure 3-1 shows one kind of hi-pot tester. The tester

shown has a “Breakdown” lamp that will glow during

the test procedure to indicate an insulation break-

down in the winding being tested.

Figure 3-1. – One Type of Hi-Pot Tester

DANGER! INSULATION RESISTANCE

TESTERS SUCH AS HI-POT TESTERS AND

MEGOHMMETERS ARE A SOURCE OF HIGH

AND DANGEROUS ELECTRICAL VOLTAGE.

FOLLOW THE TESTER MANUFACTURER'S

INSTRUCTIONS CAREFULLY. USE COMMON

SENSE TO AVOID DANGEROUS ELECTRICAL

SHOCK

DRYING THE GENERATOR

GENERAL:

If tests indicate the insulation resistance of a winding

is below a safe value, the winding should be dried

before operating the generator. Some recommended

drying procedures include (a) heating units and (b)

forced air.

HEATING UNITS:

If drying is needed, the generator can be enclosed in

a covering. Heating units can then be installed to

raise the temperature about 15°-18° F. (8°-10° C.)

above ambient temperature.

FORCED AIR:

Portable forced air heaters can be used to dry the

generator. Direct the heated air into the generator’s

air intake openings. Remove the voltage regulator

and run the unit at no-load. Air temperature at the

point of entry into the generator should not exceed

150° F. (66° C.).

CLEANING THE GENERATOR

GENERAL:

The generator can be cleaned properly only while it is

disassembled. The cleaning method used should be

determined by the type of dirt to be removed. Be sure

to dry the unit after it has been cleaned.

NOTE: A shop that repairs electric motors may be

able to assist you with the proper cleaning of gen-

erator windings. Such shops are often experi-

enced in special problems such as a sea coast

environment, marine or wetland applications,

mining, etc.

USING SOLVENTS FOR CLEANING:

If dirt contains oil or grease a solvent is generally

required. Only petroleum distillates should be used to

clean electrical components. Recommended are

safety type petroleum solvents having a flash point

greater than 100° F. (38° C.).

CAUTION!: Some generators may use epoxy

or polyester base winding varnishes. Use sol-

vents that will not attack such materials.

Use a soft brush or cloth to apply the solvent. Be

careful to avoid damage to wire or winding insulation.

After cleaning, dry all components thoroughly using

moisture-free, low-pressure compressed air.

Page 12