Rotor assembly, Stator assembly – Guardian Technologies 4270 User Manual

Page 10

Section 2

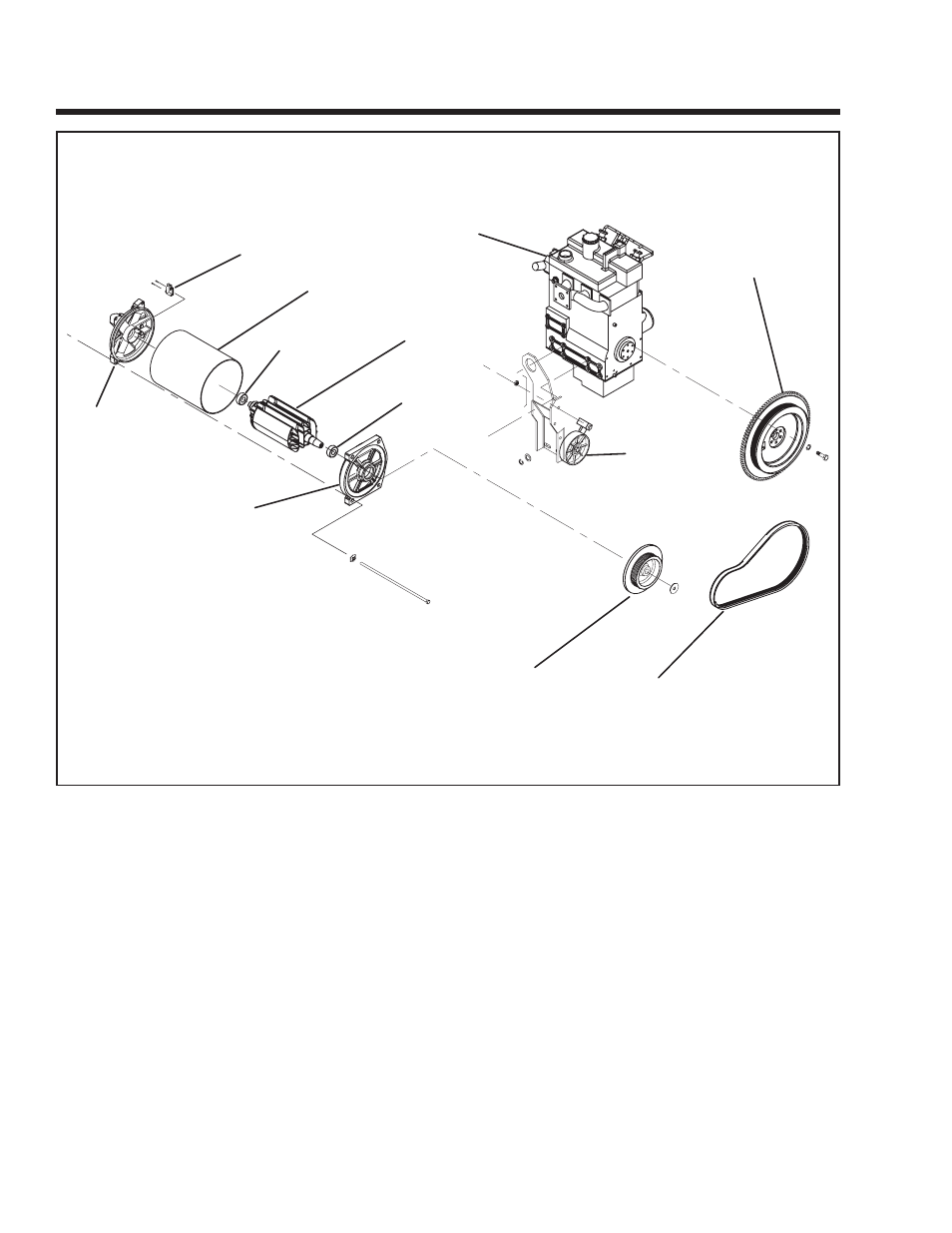

MAJOR GENERATOR COMPONENTS

ROTOR ASSEMBLY

The Rotor is sometimes called the “revolving field”,

since it provides the magnetic field that induces a

voltage into the stationary Stator windings. Slip rings

on the Rotor shaft allow excitation current from the

voltage regulator to be delivered to the Rotor wind-

ings. The Rotor is driven by the engine at a constant

speed through a pulley and belt arrangement.

The QUIETPACT 75D utilizes a 2-pole Rotor. This

type of Rotor must be driven at 3600 rpm for a 60-

Hertz AC output, or at 3000 rpm for a 50-Hertz output.

Slip rings should be cleaned. If dull or tarnished,

clean them with fine sandpaper (a 400 grit wet sand-

paper is recommended). DO NOT USE ANY METAL-

LIC GRIT OR ABRASIVE TO CLEAN SLIP RINGS.

STATOR ASSEMBLY

The Stator is assembled between the front and rear

bearing carriers and retained in that position by four

Stator studs. Windings included in the Stator assem-

bly are (a) dual AC power windings, (b) an excitation

or DPE winding, and (c) a battery charge winding. A

total of eleven (11) leads are brought out of the Stator

as follows:

1. Four (4) Stator power winding output leads (Wires No. 11, 22,

33 and 44). These leads deliver power to connected electrical

loads.

2. Stator Power winding “sensing” leads (11 and 22). These leads

deliver an “actual voltage signal to the electronic Voltage

Regulator.

Page 8

Figure 2-1. Exploded View of Generator

BRUSH HOLDER

STATOR

ROTOR

ENGINE

FLYWHEEL/PULLEY

PULLEY

TENSIONER

BELT

BEARING

BEARING CARRIER

BEARING

CARRIER

BEARING