1 general – Glow-worm EnergySaver 40 User Manual

Page 7

7

221834B

1 General

Rc

1

/

2

in.

GAS

CONNECTION

WATER

CONTENT

WATER

CONNECTION

28mm copper flow

at right return at left

LIFT

WEIGHT

240V ~ 50H

Z

, fused 3A.

ELECTRICITY

SUPPLY

1.6 Litre

(0.35 gal)

31.5 kg

(69.5 lb)

48.0 kg

(106 lb)

TOTAL

WEIGHT

40

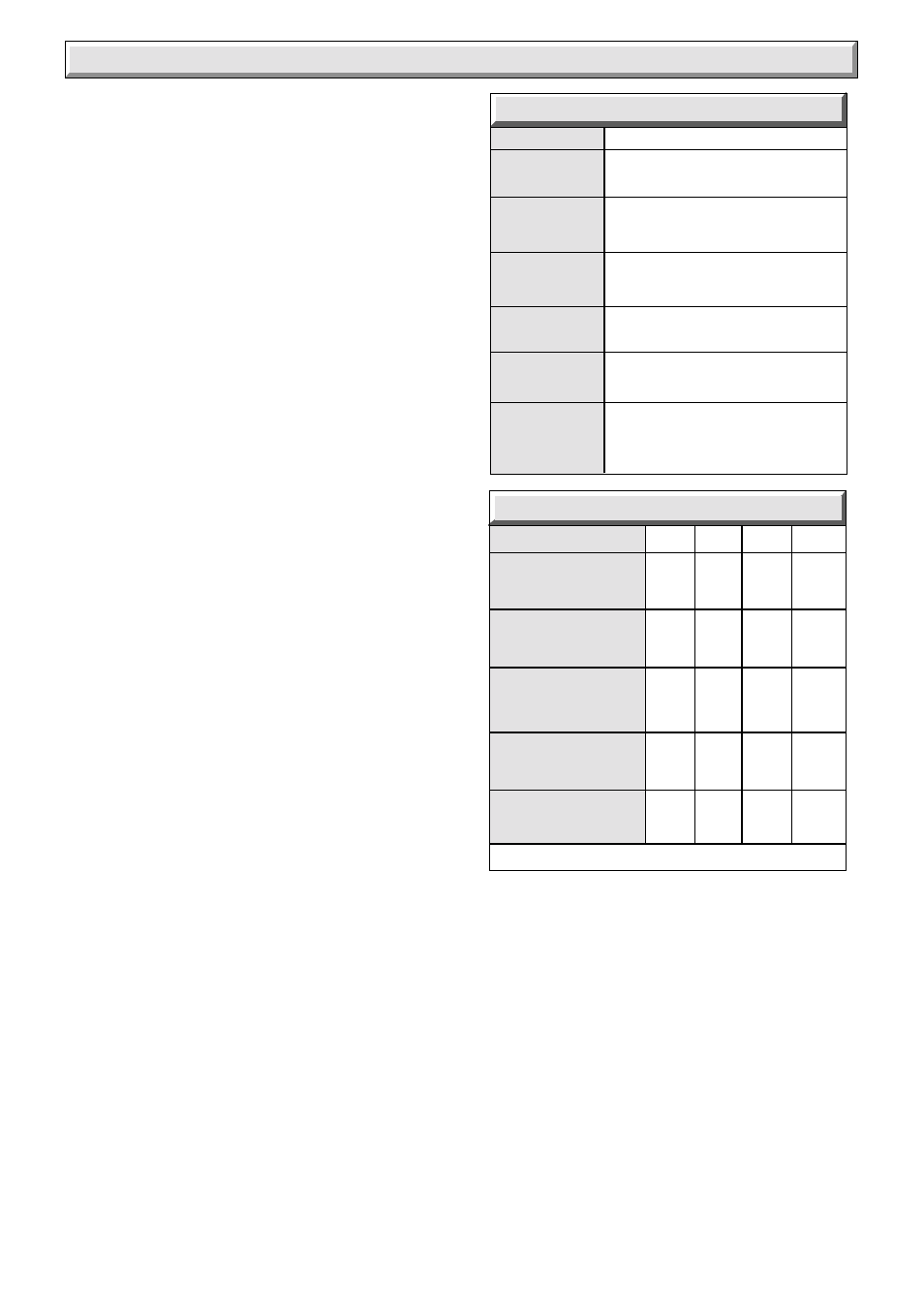

DATA TABLE 1.

MODEL

RANGE RATING

NOMINAL

kW

HEAT INPUT

(GROSS)

Btu/h

NOMINAL

kW

HEAT

OUTPUT

Btu/h

10.16

10.16

11.86

13.55

34,680 34,680 40,462 46,240

8.79

8.79

10.26

11.72

30,000 30,000 35,000 40,000

9.40

9.40

10.97

12.53

32,100 32,100 37,400 42,800

NOMINAL

kW

HEAT

OUTPUT

Btu/h

CONDENSING

BURNER

m bar

SETTING (HOT)

PRESSURE in.w.g

9.7

9.7

12.7

16.6

3.88

3.88

5.1

6.64

0.96

0.96

1.1

1.3

34

34

39.9

45.5

APPROX

m

3

h

GAS

RATE

ft

3

h

LOW

MIN

MID

MAX

TABLE 2.

Energysaver 40

BURNER INJECTOR MARKING: 40N

1.5 Gas Supply

The gas installation must be in accordance with the current

issue of BS6891.

The supply from the governed meter must be of adequate size

to provide a steady inlet working pressure of 20mbar (8in wg) at

the boiler.

On completion, test the gas installation for soundness using the

pressure drop method and a suitable leak detection fluid, purge

in accordance with the above standard.

1.6 Electrical Supply

WARNING. This boiler must be earthed.

All system components shall be of the approved type and be

wired and connected in accordance with the requirements of

the current issue of BS7671 and any applicable local regulations.

Connection of the boiler and system controls to the mains

supply must be through a common isolator and must be fused

3A maximum. This method of connection should be, preferably,

by a double pole isolating switch, provided it has a minimum

contact separation of 3mm on both poles. This should be

readily accessible and preferably adjacent to the appliance. It

should supply the appliance only and be easily identifiable as so

doing.

Alternatively, an unswitched shuttered socket outlet and 3A

fused 3 pin plug both to the current issue of BS1363 may be

used, provided that they are not used in a room containing a

bath or shower.

Wiring to the boiler must be PVC insulated type to the current

issue of BS6500 Table 16.

1.7 Condensate

The boiler condensate should, if possible, be discharged into

the household internal draining system, that is, sink or washing

machine drain. If this is not practicable, discharge can be

external, into the household drainage system or a purpose

designed soakaway

The boiler is fitted with a safety device to prevent the boiler from

working if the condensate pipe gets blocked by either ice or

debris.

It is, therefore, recommended that any external condensate

drain pipe is insulated to prevent it freezing up.

Alternatively, a larger diameter pipe can be used and insulated.

The condensate drain pipe should be checked during any

servicing and any debris found removed.

Refer to the British Gas publication “Guidance Note for the

Installation of Domestic Condensing Boilers” for further

information.

1.8 Heating System Controls

The heating system should have installed: a programmer and

room thermostat controlling the boiler.

Thermostatic radiator valves may be installed in addition to the

room thermostat.

Note: For further information, see The Building Regulations

1991 - Conservation of fuel and power, 1995 edition - Appendix

G, table 4b.

1.9 Anti-theft Kits

Anti-theft kits are available for these appliances, contact

Hepworth Heating Ltd. for further information.