Grizzly Gear-Head G9036 User Manual

Page 22

-20-

Model g9036 Mfg. 7/08+

spindle speed levers

the spindle speed levers (

figure 14) control the

speed that the spindle rotates. the chart below

the levers indicates the different lever configura-

tions required to make the spindle rotate at vari-

ous speeds.

never move this lever while the

spindle is moving.

feed direction lever

the feed direction lever (

figure 14) controls

which direction the feed rod rotates when the

spindle lever is used. this allows you to change

feed directions without changing the direction of

spindle rotation.

never move this lever while the

spindle is moving. refer to page 35 for details of

how to use this lever for operations.

feed speed controls

these knobs and levers (

figure 14) control feed

speeds and leadscrew engagement for threading

and turning.

figure 15. Brake.

Brake

carriage handwheel

the carriage handwheel (

figure 16) moves

the carriage left or right along the bed. this

handwheel is used when setting up the machine

or when manual control is desired during turning

operations.

cross slide handwheel

the cross slide handwheel (

figure 16) moves

the cross slide toward and away from the work.

turning the dial clockwise moves the slide toward

the workpiece. the graduated dial can be adjust-

ed by holding the handwheel with one hand and

turning the dial with the other.

compound slide handwheel

the compound slide handwheel (

figure 16) con-

trols the position of the cutting tool relative to the

workpiece. this slide is adjustable to any angle

within its range. the graduated dial is adjustable

using the same method as the dial on the cross

slide. Angle adjustment is locked by hex nuts on

the base of the top slide.

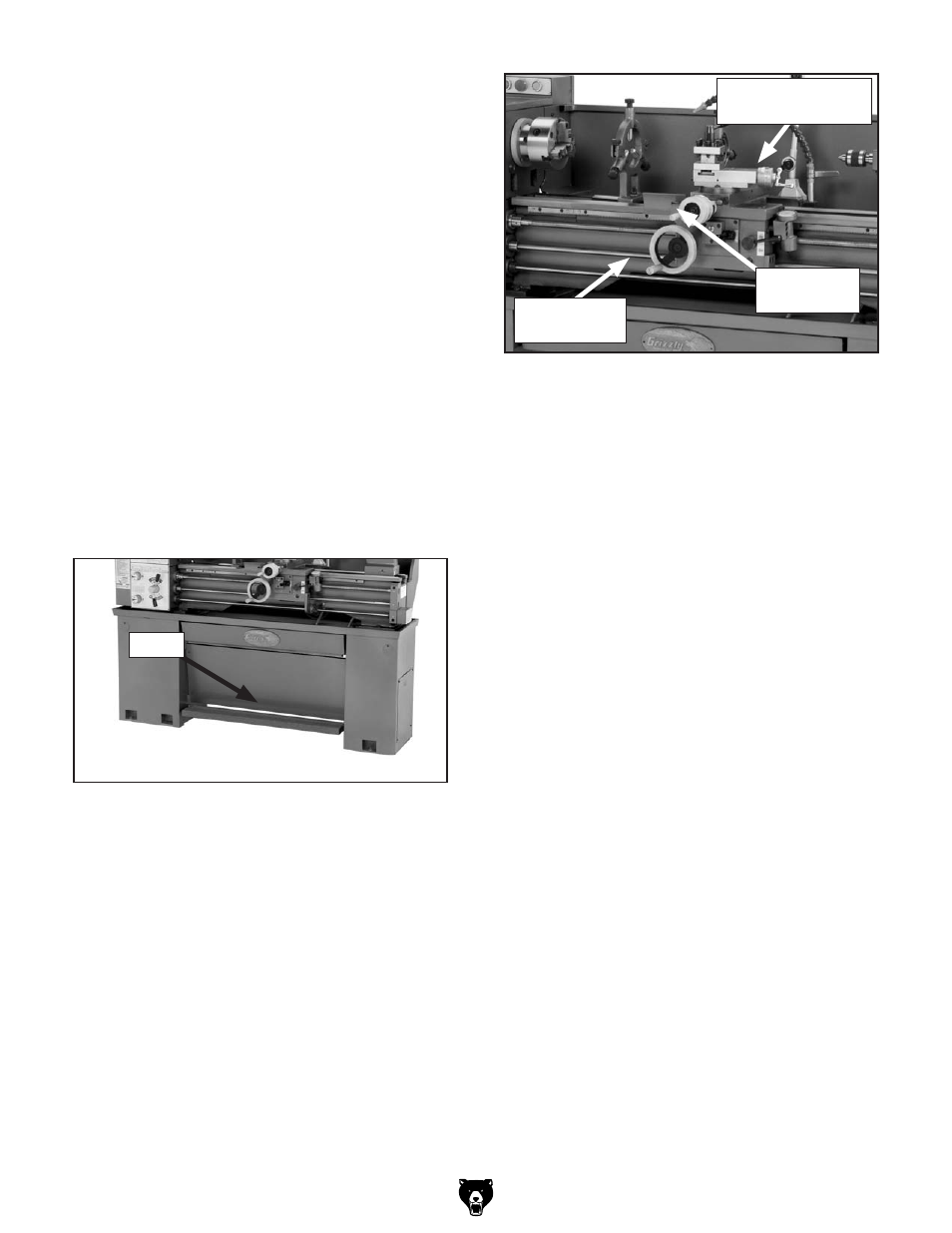

figure 16. Carriage handwheel controls.

Cross slide

handwheel

Carriage

handwheel

Compound slide

handwheel

brake

the brake (

figure 15) physically stops the spin-

dle and cuts power to the motor when pressed

down.