Notice – Grizzly Gear-Head G9036 User Manual

Page 19

Model g9036 Mfg. 7/08+

-17-

4. Make sure all tools and objects used during

setup are cleared away from the machine.

5. disengage the half nut lever and the feed

lever (

figure 12), and make sure the saddle

lock bolt is loosened (do not loosen the sad-

dle lock bolt too much—see

page 52).

9. push the poWer stArt button, then move

the spindle lever (

figure 12) down to start

the spindle.

—When operating correctly, the machine

runs smoothly with little or no vibration or

rubbing noises.

— investigate and correct strange or unusual

noises or vibrations before operating the

machine further. Always disconnect the

machine from power when investigating

or correcting potential problems. if the

problem is not readily apparent, refer to

troubleshooting on page 48.

10. Move the spindle lever up to the center posi-

tion, and press the stop button in.

11. Without resetting the stop button, move

the spindle lever down. the machine should

not start.

—if the machine does not start, the stop but-

ton safety feature is working correctly.

—if the machine does start (with the stop

button pushed in), immediately disconnect

power to the machine. the stop button

safety feature is not working correctly. this

safety feature must work properly before

proceeding with regular operations. Call

tech support for help.

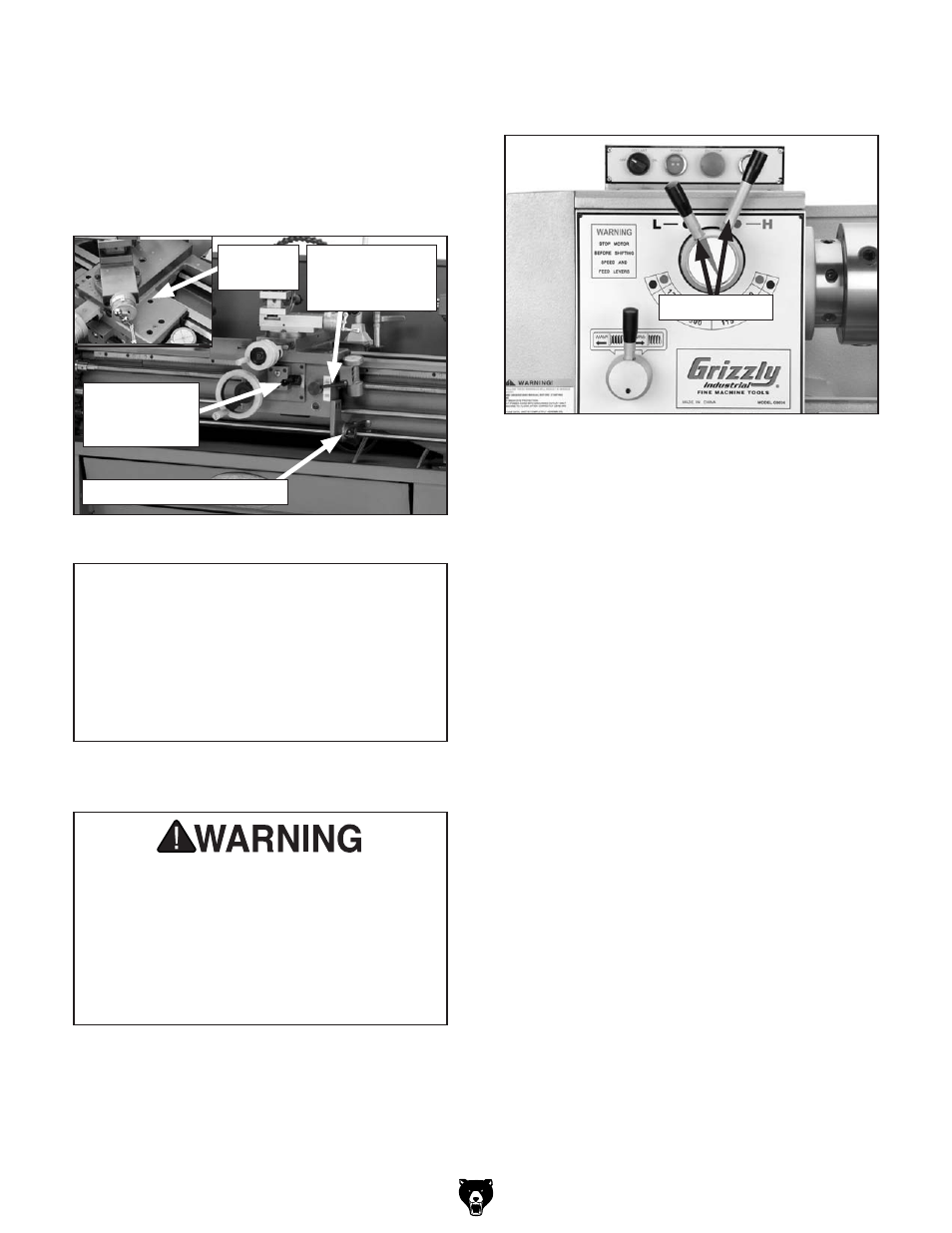

figure 13. headstock controls.

speed levers

8. Move the spindle speed levers to 70 rpM

(

figure 13).

7. rotate the red stop button (figure 13) clock-

wise so it pops out.

NOTICE

never shift lathe gears when lathe is

operating, and make sure both the half nut

lever and the feed lever are disengaged

before you start the lathe! otherwise the

lathe may feed the apron into the chuck or

tailstock and cause severe lathe damage.

before starting the saw, make sure you

have performed any preceding assembly

and adjustment instructions, and you have

read through the rest of the manual and

are familiar with the various functions and

safety features on this machine. failure to

follow this warning could result in serious

personal injury or even death!

6. Connect power to the machine.

figure 12. Apron controls.

half nut lever

is pulled up

(disengaged)

Feed lever is

horizontal

(disengaged)

spindle lever is Centered

saddle

lock Bolt