Sanding drum/ sleeve installation, Sanding – Grizzly Oscilatign Spindle GO739 User Manual

Page 19

Model g0739 (Mfg. since 2/12)

-17-

Sanding Drum/

Sleeve Installation

to ensure the workpiece is supported during sand-

ing operations, use the table insert that matches

the corresponding drum and sleeve (see table

below). it is important to keep the gap between

the table insert and drum as small as possible to

reduce the risk of a pinch hazard.

Sanding

Sleeves

Sanding

Drums

Table

Inserts

Spindle

Washers

1

⁄

2

"

n/A

1

⁄

2

"

5

⁄

8

"

3

⁄

4

"

3

⁄

4

"

3

⁄

4

"

7

⁄

8

"

1"

1"

1"

7

⁄

8

"

1

1

⁄

2

"

1

1

⁄

2

"

1

1

⁄

2

"

1

3

⁄

4

"

2"

2"

2"

1

3

⁄

4

"

3"

3"

3"

1

3

⁄

4

"

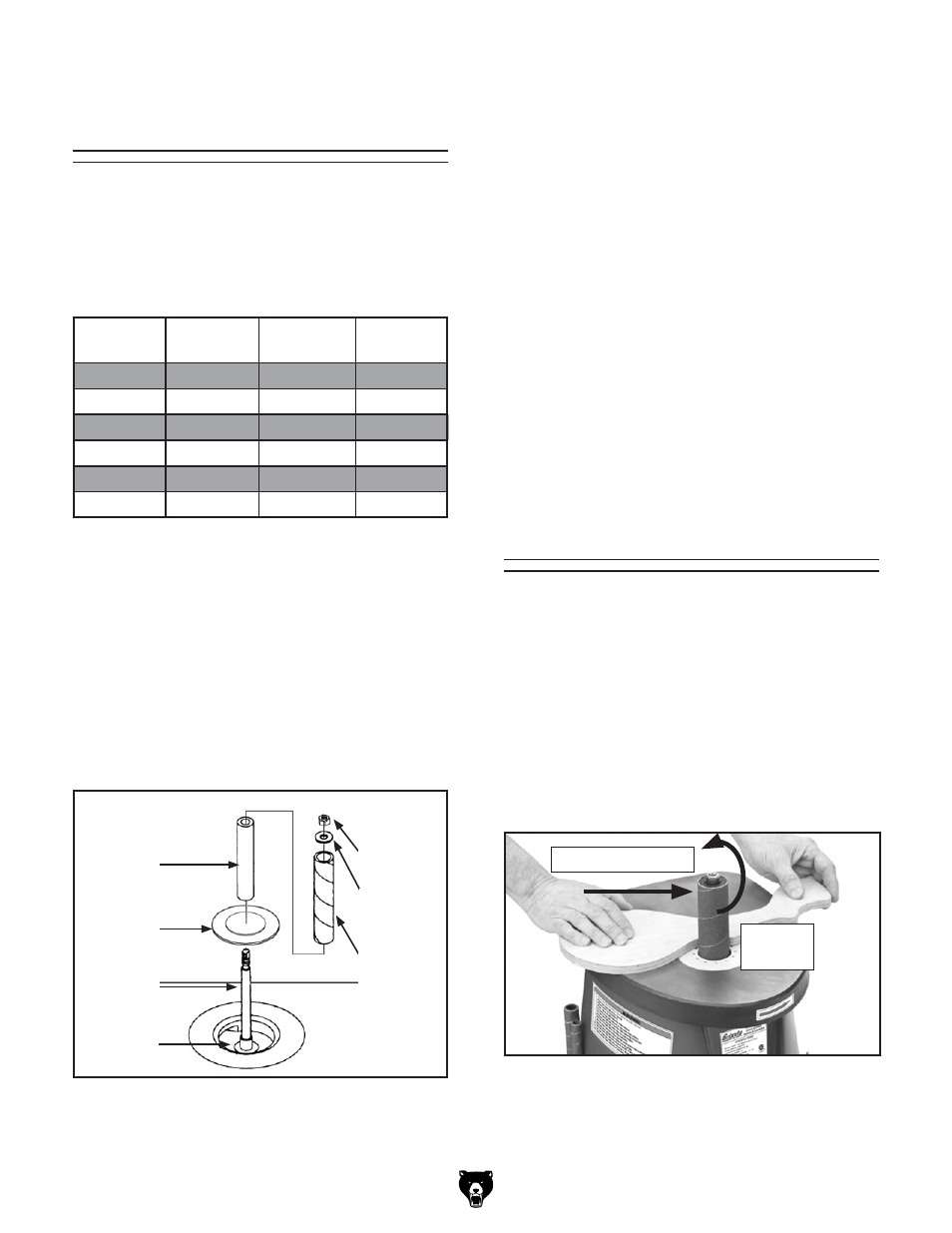

To install or replace a sanding drum/sleeve:

1. disConnECt sAndEr FroM poWEr.

2. While holding the sanding drum and sleeve,

use the arbor wrench to loosen and remove

the spindle hex nut.

3. remove the spindle washer, sanding sleeve,

sanding drum, table insert and base washer

(see

figure 13).

4. Clean the table opening for the table insert

and any other spindle areas as necessary.

there should be no sawdust on the ledge of

the table opening where the table insert is

placed or the table insert will not sit flush with

the table.

5. Use the table on this page to select the

required size of components for the sanding

drum/sleeve size you have chosen.

6. insert the base washer, then install the

desired sanding drum on the spindle shaft,

followed by the corresponding sanding sleeve

on the drum, as shown in

figure 13.

7. secure the sanding drum with the appropri-

ate spindle washer and the spindle hex nut.

tighten until the rubber sanding drum places

slight pressure on the sanding sleeve.

figure 13. removal/installation order of sanding

drum components and table inserts.

sanding

drum

table

insert

spindle

spindle

hex nut

spindle

Washer

sanding

sleeve

Base

Washer

Sanding

To sand a workpiece:

1. turn the spindle sander ON and allow it to

reach full speed.

2. Using both hands to maintain control of the

workpiece, guide the workpiece against the

rotation of the spindle, as shown in

figure

14. do not force the workpiece against the

sanding sleeve. Allow the machine to do the

work.

figure 14. sanding workpiece.

spindle

rotation

sanding direction