GE EZ2 Series User Manual

Page 6

2.4

Feed Water Requirements

The following feed water requirements must be met before installing your E2/EZ2-Series

machine to ensure quality permeate and extended membrane element life. Refer to

Table 2.2 (

E2/EZ2-

Series Feed Water Requirements) for feed water information.

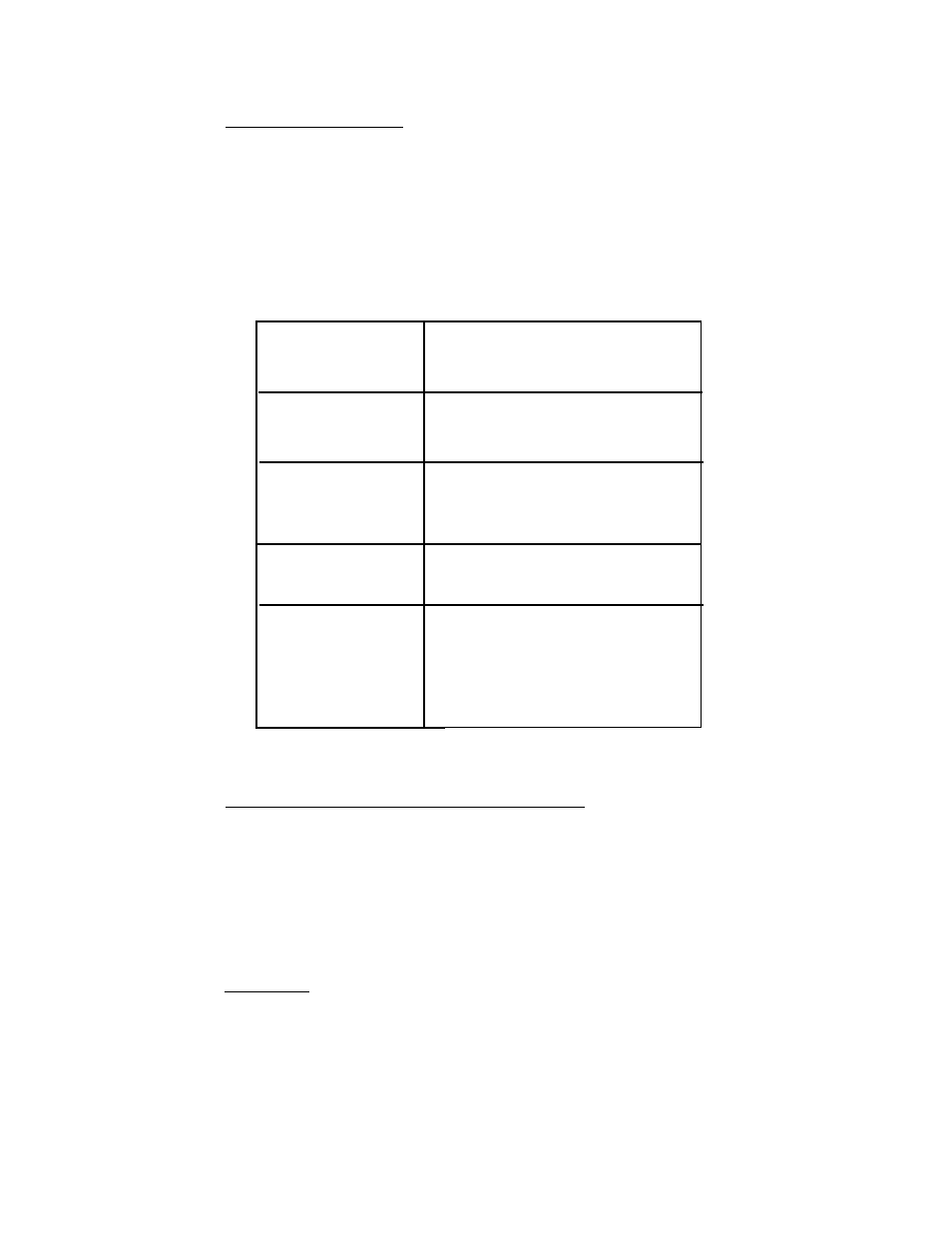

Table 2.2

E2/EZ2-Series Feed

Water Requirements

*

American Standard for Testing Materials

2.5

Transporting Pure Water (Permeate) to Point-of-Use

Pure water, or permeate, is in an aggressive state and should only be transported from the

machine to the point-of-use in food grade flexible nylon, stainless steel (SS) tubing, or

polyvinyl chloride (PVC) material for the inlet, permeate, and concentrate piping sizes.

Refer to Connections (Table 2.1, E2/EZ2-Series Machine Plumbing Connections) for

inlet, permeate, and concentrate piping sizes.

WARNING:

MACHINE DAMAGE MAY OCCUR IF PERMEATE BACK PRES-

SURE EXCEEDS 60 PSI (4.1 BAR) DURING OPERATION.

2

Temperature

Inlet Pressure

Chlorine

(continuous feed)

Operating pH

Silt Density Index

(SDI)

Typical: 50° - 85°F (10° - 29°C)

Limits:

33° - 104°F (0.60° - 40°C)

Minimum:

30 psig (2.1 barg)

Maximum:

60 psig (4.1 barg)

0 parts per million (ppm)

5.5 - 8.5

Less than or equal to 5 to minimize

membrane element fouling and

extend cleaning intervals. Refer to

ASTM* Standard D4189.