Notice, Outboard turning – Grizzly 18" x 47" Wood Lathe G0733 User Manual

Page 32

-30-

Model G0733 (Mfg. Since 10/11)

3. thread and secure the faceplate onto the

headstock spindle (refer to

Headstock

faceplate on page 25 for faceplate mount-

ing instructions).

— if wood screws cannot be placed in the

workpiece, the faceplate can be mount-

ed to a backing block attached to the

workpiece (see

Mounting the Workpiece

to a backing block).

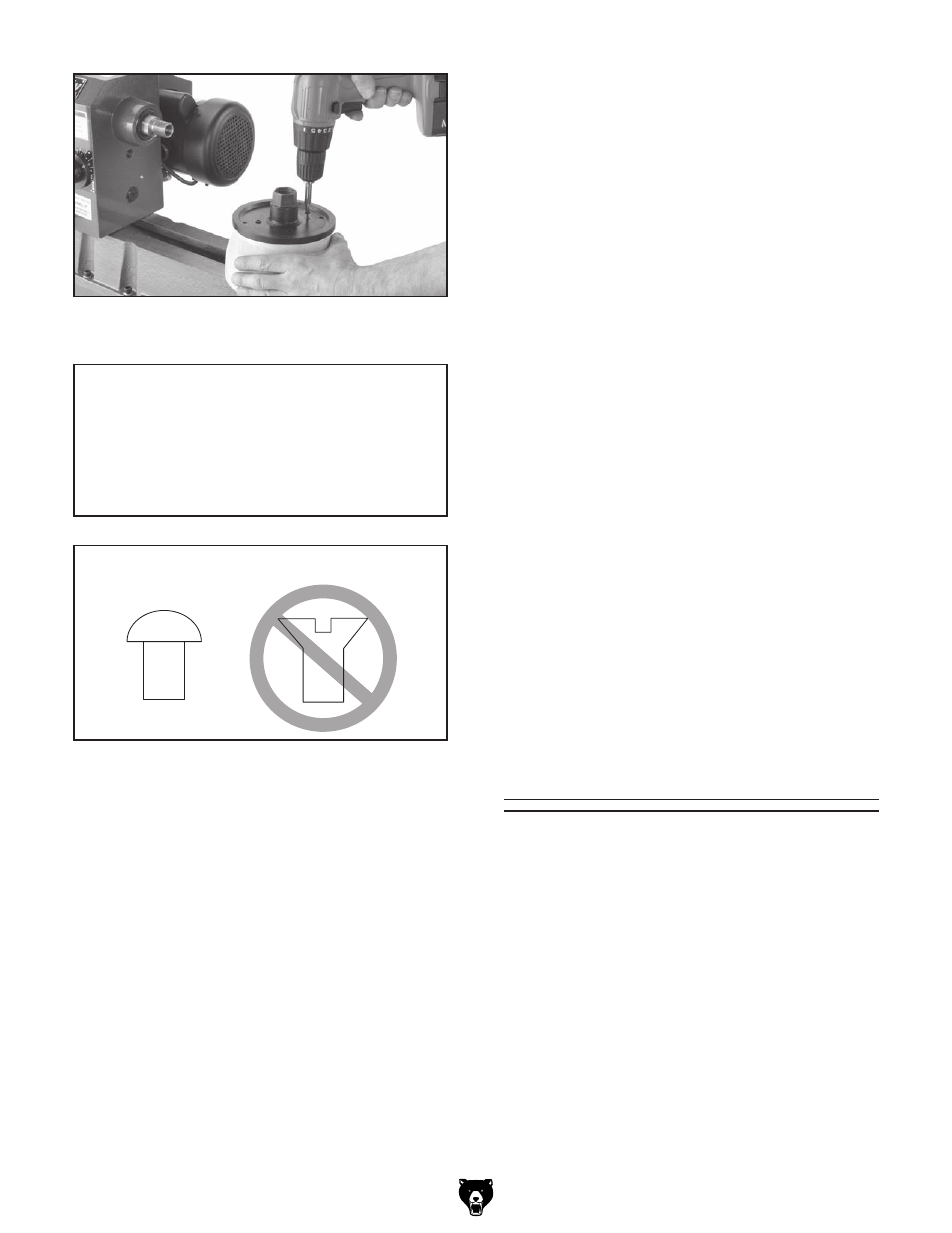

Correct

Incorrect

figure 41. Correct and incorrect screw types.

NOTICE

Only use screws with non-tapered heads

(see figure 41) to attach the faceplate to

the workpiece. Screws with tapered heads

can split the faceplate or snap off during

operation.

figure 40. typical attachment of faceplate to

workpiece.

1. make the backing block from a suitable size

piece of scrap wood.

Note:

The faces of the backing block must be

flat and parallel to each other, or the uneven

surfaces will cause the workpiece to spin

eccentricly, causing unnecessary vibration

and runout. It is best to mount the backing

block to the faceplate and turn the other sur-

face flat prior to mounting.

2. locate and mark the center of both the

workpiece and backing block.

3. drill a

1

⁄

4

" hole through the center of the

backing block.

4. look through the hole in the backing block

to line up the center with the workpiece and

glue and clamp the backing block to the

workpiece.

Note: Allow the glue to cure according to the

manufacturer's instructions.

5. Follow Steps 1–3 under Mounting the

Workpiece onto the faceplate (see page

33) to attach the backing block to the face-

plate.

Mounting Workpiece to backing

block

Outboard Turning

outboard turning is a variation of faceplate turning

and is accomplished with the headstock positioned

so the faceplate is not directly over the bed, allow-

ing a larger turning capacity than the swing speci-

fication of the lathe. on the g0733, the maximum

workpiece diameter that can safely be outboard-

turned is limited to 17".

the only way to rotate the headstock on this

machine is to remove it from the bed first, which

can be a heavy and cumbersome task. a much

simpler alternative to removing the headstock

is to simply remove the tailstock and slide the

headstock to the other end of the bed. this will

position the spindle so it is not directly over the

bed whereby outboard turning can safely be

accomplished.