Setting the open position limit, Step 3, Step 4 – GTO 2502 User Manual

Page 37: Step 1, Step 2, Step 5

33

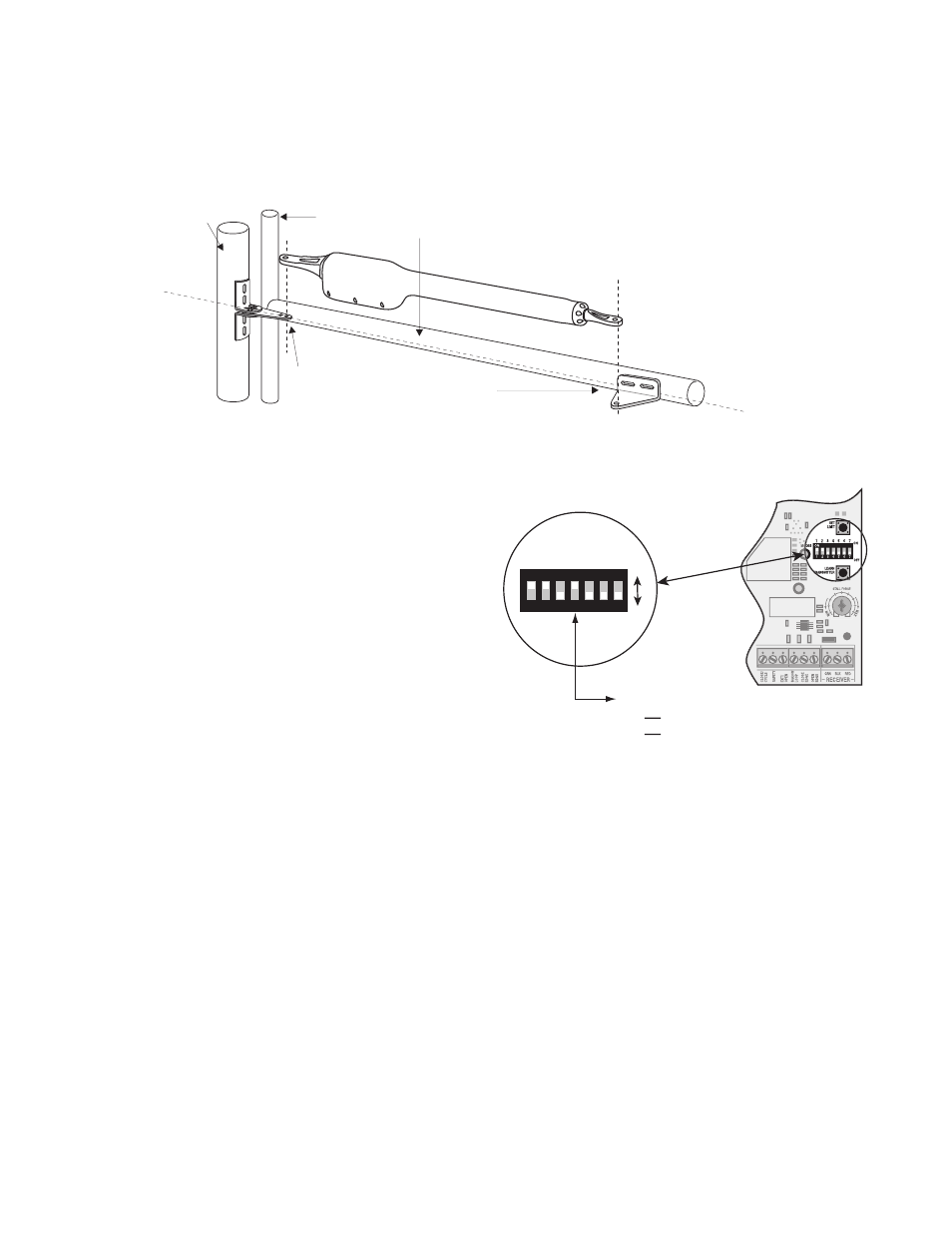

Operator

Fence Post

Gate Post and Gate Cross Member

(In Closed Position)

POST PIVOT BRACKET level with the

horizontal surface of the GATE BRACKET

LEVEL

LEVEL

LEVEL

Step 3

With the gate in the fully closed position and the opener retracted, swing the opener to the gate. Mark reference points for

bolt holes on gate cross member through middle of gate bracket slots. The opener must be level. (Some vertical adjustment

is possible by sliding the post bracket assembly up and down.) Drill

3

/

8

" holes into the gate cross member as marked. Fasten

gate bracket to cross member using (2) 3/8" x 3" bolts, washers, lock washers, and nuts. Attach the opener to the post bracket

assembly and gate bracket using clevis pins, bushings, and hairpins clips.

Step 4

Make sure the control box power switch is OFF. Use a small

screwdriver to move the

Number 4 DIP switch from the factory

setting (OFF / Pull-To-Open) to ON for Push-To-Open. Turn

power switch

ON. The control board is now configured to push

the gate open.

Setting the Open Position Limit

Step 1

Confirm that the power switch is in the ON position, and the gates are in the CLOSED POSITIONS.

Step 2

Activate your openers by pressing the entry transmitter button. Your gates should now be moving from the closed positions

toward their open position. Prepare to STOP gates by pressing the entry transmitter button again when the first gate reaches

the desired open position. This step may be repeated until desired open position is achieved. Once the desired OPEN

position has been achieved, proceed to step 3.

Step 5

Install the second gate opener on the other gate in the same

manner. Then refer to the CONTROL BOARD SETTINGS

on page 25 for gate sequencing and other programming steps

before proceeding.

1

ON

2 3 4 5 6 7

ON

OFF

1 2 3 4 5 6 7

DIP#4

ON

Push-to-open operation.

OFF

Pull-to-open operation (factory setting).