Unpacking inventory, Assembly – Grizzly T23091 User Manual

Page 8

Model t23091

1

⁄

4

" Air die grinder

-6

-

your tool was carefully packaged for safe

transportation. remove the packaging

materials from around your tool and inspect

it. if you discover the tool is damaged,

please immediately call Customer Service

at (570) 546-9663 for advice.

save the containers and all packing

materials for possible inspection by the

carrier or its agent. otherwise, filing a

freight claim can be difficult. When you are

completely satisfied with the condition of

your shipment, inventory the contents.

if any non-proprietary parts are missing

(e.g., a nut or a washer), we will gladly

replace them; or for the sake of expediency,

replacements can be obtained at your

local hardware store.

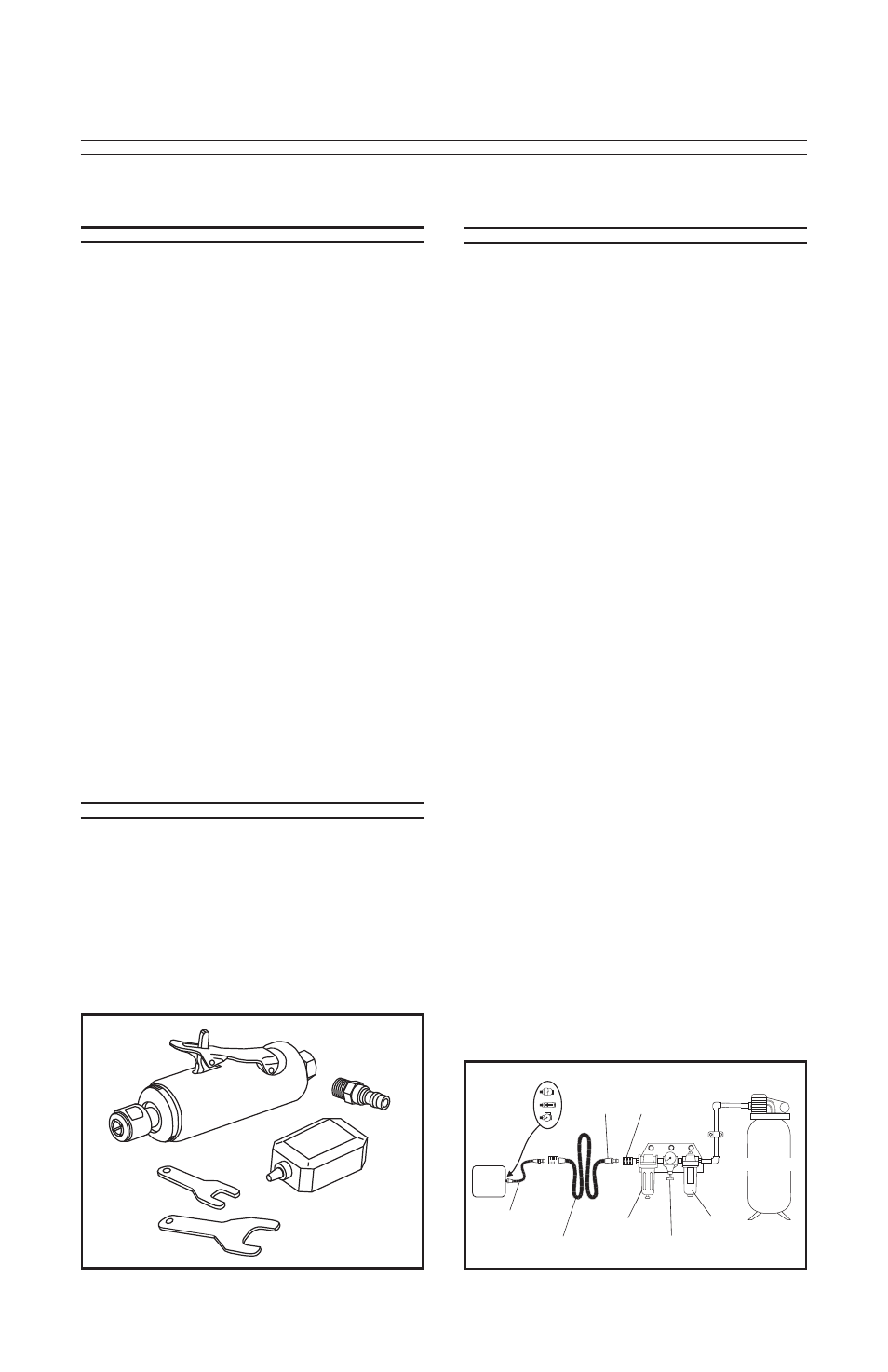

model t23091 inventory (figure 2)

a. die grinder .........................................1

b. Quick disconnect Air Fitting ...............1

c. Bottle for oil .......................................1

d. spindle Wrench

1

⁄

2

" ............................1

e. Collet nut Wrench

11

⁄

16

" ......................1

section 2: setup

unpacking

inventory

figure 2. inventory.

a

b

c

e

d

assembly

to assemble the grinder:

1. remove the plastic plug from the

grinder air inlet.

2. Apply pipe sealant on the quick

disconnect fitting threads, and install

the fitting into the grinder air inlet.

3. insert the shank of the desired grinding

bit into the collet until it bottoms, and

tighten the collet nut (see

figure 1)

using the spindle and collet wrenches.

4. release the trigger lock, depress the

trigger, place a few drops of air tool

oil into the air inlet, and release the

trigger. the grinder is ready for use.

air supply setup tips:

•

if the air hose is longer than 25-feet,

increase the air pressure to 100 psi to

compensate for air flow restriction.

•

For consistent air flow, use air hoses

with an inside diameter of

3

⁄

8

" or larger.

•

to eliminate air system moisture and

maintain automatic lubrication, install a

main or in-line filter water separator as

far as possible from the air compressor,

but before any automatic in-line oiler.

see examples in

figure 3.

Fittings

Water

Separator

Air

Regulator

Automatic

Oiler

Main Air

Supply Hose

Male Female

Air Piping

Filter

In-Line

Your

Tool

Oiler

Filter

Regulator

Quick-Disconnect

Lead-In Hose

(Optional)

(Optional)

Steel

Compressor

figure 3. typical air supply system.