Using the parallel fence guide, Dust extraction, Using the redeye® system – Global Machinery Company LS236LS User Manual

Page 12

Note.

Since blade thickness varies, always make a trial

cut in scrap material along the guideline to determine

how much, if any, the guideline must be offset to get

an accurate cut.

Using the parallel fence guide

The parallel fence allows you to make parallel cuts in

a sheet of wood, all at the same width.

CAUTION.

Always ensure that the saw is switched off

and unplugged from the power supply before making

any adjustments.

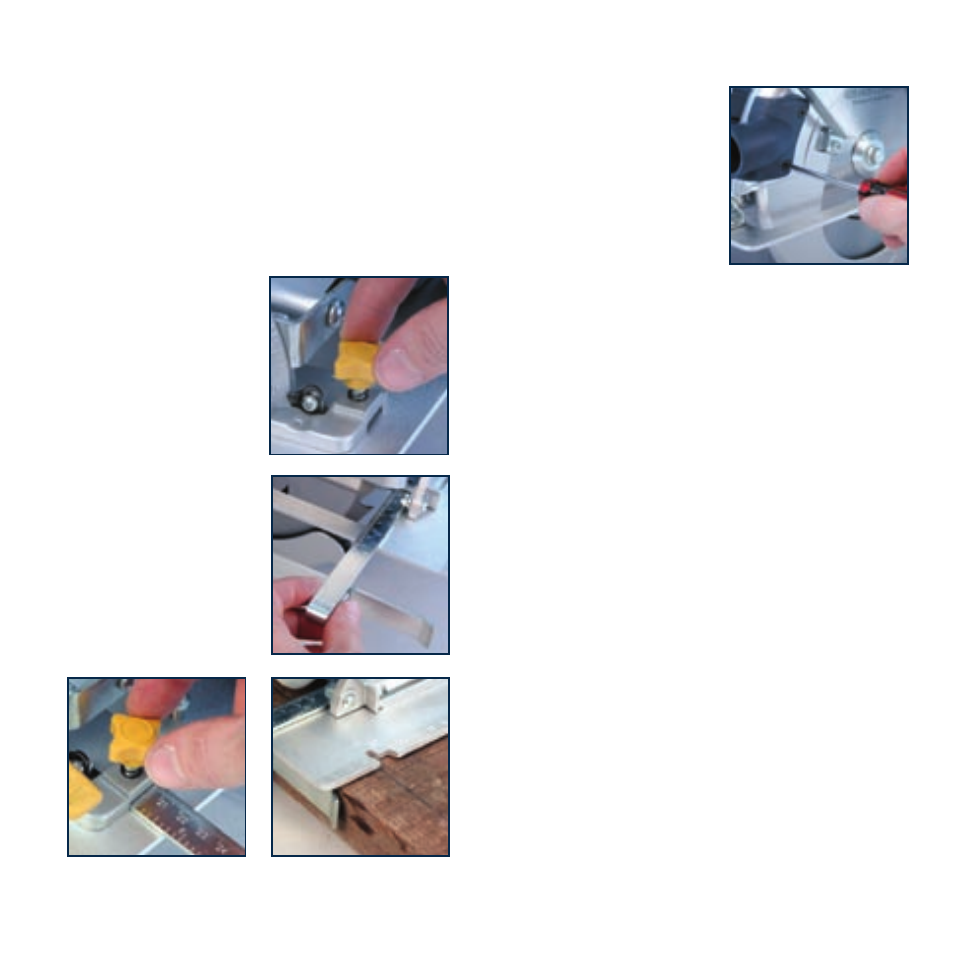

1. Loosen the parallel fence

locking knob (10)

2. Slide the parallel fence

(11) through the slots

in the base plate (14).

3. Adjust the parallel

fence to the

required width and

secure it in position with

the parallel fence locking

knob (10).

4. Ensure that the fence

rests against the wood

along its entire length

to give a consistent

parallel cut.

Dust extraction

The tool can be connected to a

dust extraction system via the

dust extraction adaptor (17).

1. Fit the dust extraction

adaptor (17) over the dust

extraction port (16).

2. Using the two phillips head

screws supplied secure the

dust extraction port onto

the saw.

3. Connect your dust extraction equipment onto the dust

extraction adaptor.

Using the REDEYE® system

WARNINGS.

Do not stare directly at the laser beam.

Never aim the beam at any person or an object other

than the work piece.

Do not deliberately aim the beam at personnel and ensure

that it is not directed towards the eye of a person for

longer than 0.25s.

Always ensure the laser beam is aimed at a sturdy work

piece without reflective surfaces. I.e. wood or rough

coated surfaces are acceptable. Bright shiny reflective

sheet steel or the like is not suitable for laser use as

the reflective surface could direct the beam back at the

operator.

Only turn laser beam on when tool is on work piece.

1. Mark the line of the cut on the work piece.

2. Adjust the depth of cut and bevel angle as required.

3. Rest the front edge of the base on the work piece.

4. Switch on the laser beam by pressing the laser light

on/off button (4).

5. Start the motor by squeezing the trigger switch (3).

12