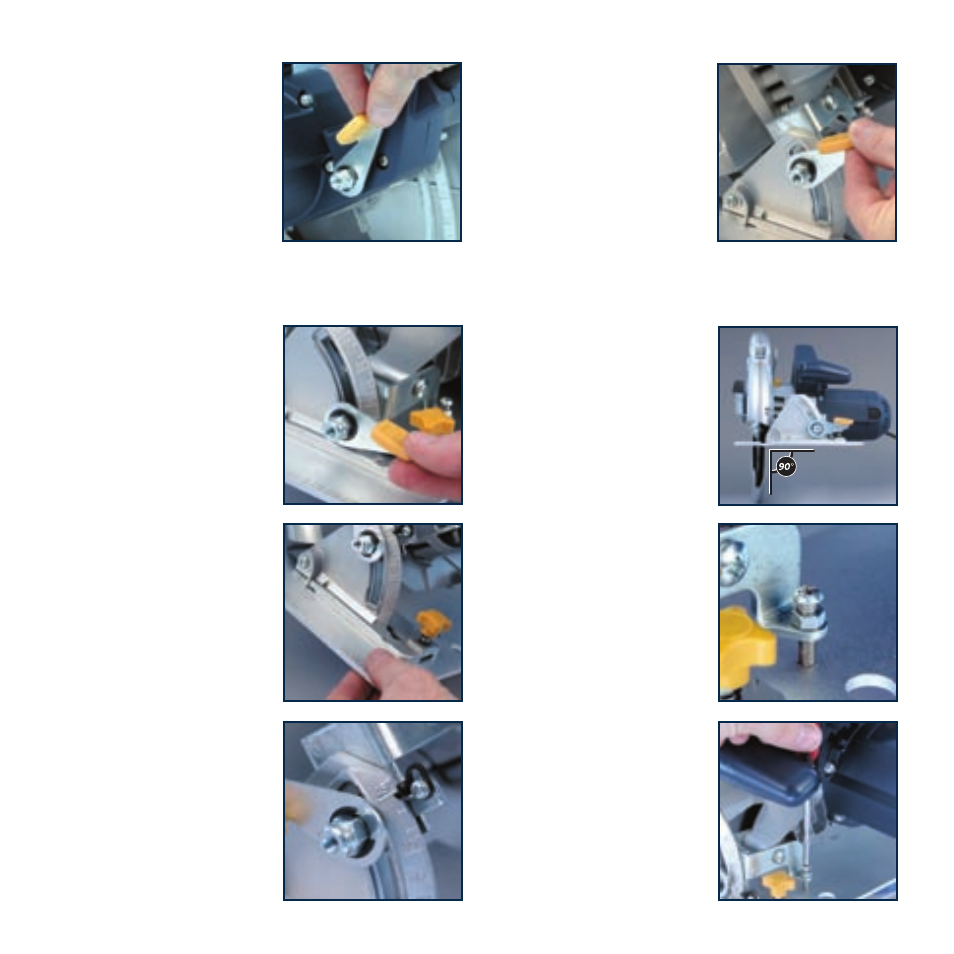

Adjusting the bevel angle, Adjusting the bevel setting – Global Machinery Company LS236LS User Manual

Page 10

Note.

Always use the correct

blade depth setting. The

correct blade depth setting for

all cuts should not be more

than 6mm below the material

being cut. Allowing more

depth will increase the chance

of kickback and result in a

rough cut.

Adjusting the

bevel angle

CAUTION.

Always ensure that

the saw is switched off and

unplugged from the power

supply before making any

adjustments.

1. The saw can be adjusted to

cut at any angle between

0° and 45°. When making

45° bevel cuts, there is

a notch (23) in the saw

base to help you line up

the blade with the line of

cut. Align your line of cut

with the inner blade guide

notch on the base of the

saw when making 45°

bevel cuts.

2. Loosen the bevel

adjustment lever (8)

located at the front of the

base plate.

3. Tilt the body of the saw

until the required angle is

reached using the bevel

scale (9) as a guide.

4. Tighten the bevel

adjustment lever (8) to

secure the base plate.

Note.

Always make a trial

cut in a scrap piece of

material along a guideline

to determine how much you

should offset the blade from

the guideline to make an

accurate cut.

Adjusting the bevel

setting

CAUTION.

Always ensure that the saw is switched off

and unplugged from the power supply before making any

adjustments.

1. Ensure power is

disconnected from the

mains socket.

2. With the saw turned upside

down and the lower guard

fully retracted, check that

the saw blade is at 90° to

the base.

3. If adjustment is necessary,

adjust as follows.

4. Loosen the lock nut of the

stop screw found beside the

parallel fence locking knob

(10) and turn it either in

or out to adjust the base

down onto the screw.

4. Re-check the blade until it

is at 90° to the base.

5. Lock the screw with the

lock nut.

10