Drum adjustments – Grizzly G0459 User Manual

Page 31

G0459 12" Drum Sander

-29-

Tools Needed:

Qty

Hex Wrench 4mm .............................................. 1

Wrench 19mm ................................................... 1

Wrench 10mm ................................................... 1

Socket 14mm .................................................... 1

Measuring Tape ................................................ 1

Gauge Blocks (see

Page 26) ............................ 2

Feeler Gauge Set .............................................. 1

For the Model G0459 Drum Sander to function

properly, the sanding drum must be aligned in

two directions: (1) parallel to the conveyor belt

and (2) perpendicular to feed direction.

The drums can be adjusted in fine increments at

the pillow block bearings and in larger increments

by using the table lift screws (

Page 33).

While adjusting the drum, keep in mind that hav-

ing the drum parallel to the conveyor belt is critical

to the sanding operation. Care should be taken to

make the tolerances as close as possible (within

0.002" from one side to the other) when adjusting

the drum height.

The tolerances for having the drum perpendicular

to the feed direction are much more forgiving,

even allowing up to

1

⁄

8

" difference from one side

to the other before causing problems.

To align the sanding drum parallel to the con-

veyor belt (Figure 28):

Drum Adjustments

������������

�������������

Figure 28. Drum parallel to conveyor belt.

Locknut

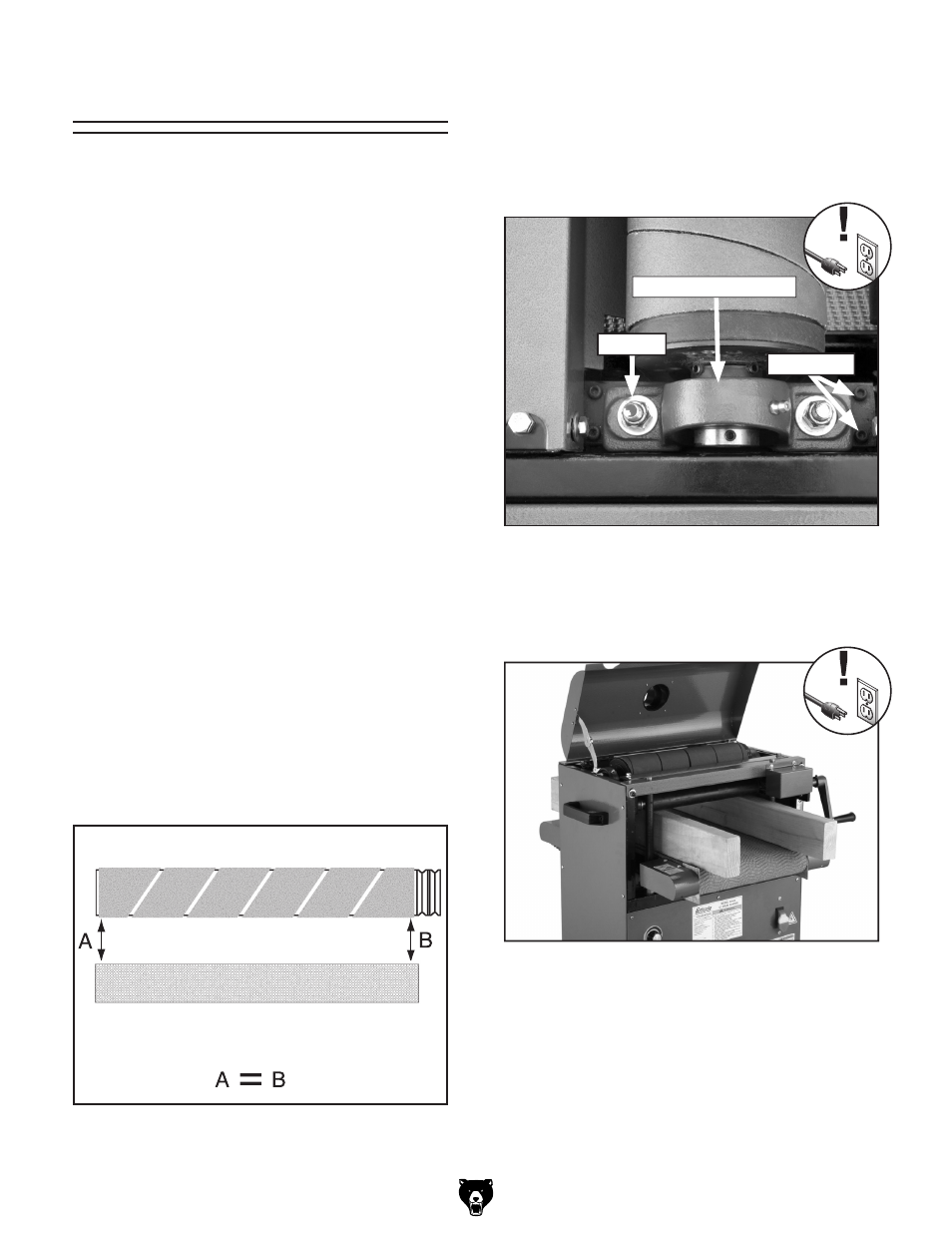

Figure 29. Pillow block bearing adjustments.

Pillow Block Bearing

4. Place the gauge blocks on the conveyor table

and position them under the pressure rollers,

as shown in

Figure 30.

Figure 30. Gauge blocks positioned under

pressure rollers and sanding drum.

5. Raise the table until the gauge blocks just

touch the bottom of the sanding drum.

N

ote: A good way to know when they are

touching is to rock the sanding drum back

and forth while raising the table until you hear

or feel contact with the gauge blocks.

1. DISCONNECT POWER TO THE SANDER!

2. Open the top cover.

3. Loosen the lock nuts (see Figure 29) on the

drum pillow block bearing.

Setscrews