Grizzly G0459 User Manual

Page 24

-22-

G0459 12" Drum Sander

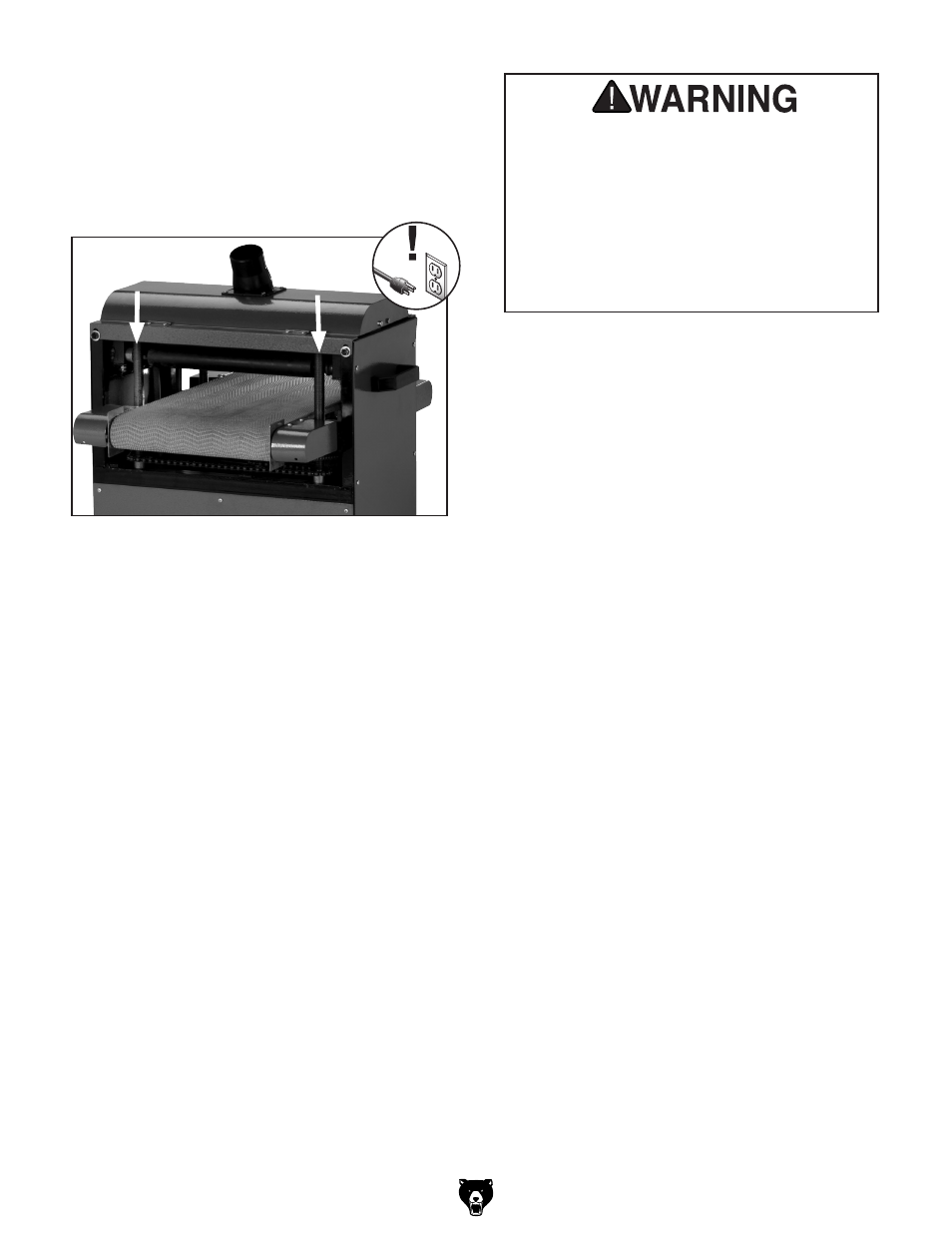

Table Lift Screws: These should be lubricated

with lithium grease every six months.

Clean the table lift screws (

Figure 21) and rub

lithium grease onto the threads. Move the table

up or down to spread the grease thoroughly over

the threads.

Failure to routinely inspect your drum sander

for damage and wear could result in unsatis-

factory work results, premature component

or machinery failure, or operator injury. We

recommend you create a checklist for routine

inspection and maintenance. Remember to

always disconnect the drum sander from its

power source before attempting to inspect,

adjust, or repair this machine!

Figure 21. Table lift screws.

See also other documents in the category Grizzly Grinding machines:

- G0574 (32 pages)

- H7760 (32 pages)

- H2881 (1 page)

- 9962ZX (80 pages)

- G0565 (32 pages)

- G0473 (24 pages)

- 6" random orbital sander H8120 (4 pages)

- G1276 (34 pages)

- G1071 (40 pages)

- Pneumatic Sanding Drum G1970 (1 page)

- G9983 (60 pages)

- Air Belt H0596 (4 pages)

- G1079 (54 pages)

- G1066 (54 pages)

- G9907 (10 pages)

- G0512 (44 pages)

- G1014Z (27 pages)

- G1600 (1 page)

- H7672 (20 pages)

- 7" Angle Sander H0592 (2 pages)

- G0547 (35 pages)

- G0489 (28 pages)

- G0459P (56 pages)

- G0563 (52 pages)

- 12" Drum Sander G0459 (56 pages)

- G1971 (1 page)

- G0486/G0487 (76 pages)

- Drum H2882 (1 page)

- 7" Angle Polisher H0593 (2 pages)

- G0679 (11 pages)

- H8192 (36 pages)

- H3140 (32 pages)

- G3105 (26 pages)

- G0458 (48 pages)

- H8215 (8 pages)

- G9984 (44 pages)

- G0445 (80 pages)

- G1066Z (54 pages)

- G5049Z (26 pages)

- G9910 (10 pages)

- G8749 (24 pages)

- G1870 (2 pages)

- G0571 (3 pages)

- G0475 (20 pages)

- Oscilatign Spindle GO739 (32 pages)