6 pre-installation (cont.), 7 air supply and ventilation – Frymaster BK1814 User Manual

Page 13

Frymaster BK1814 Series Gas Fryer

Chapter 2: Important Information

2-4

2.6 Pre-installation (cont.)

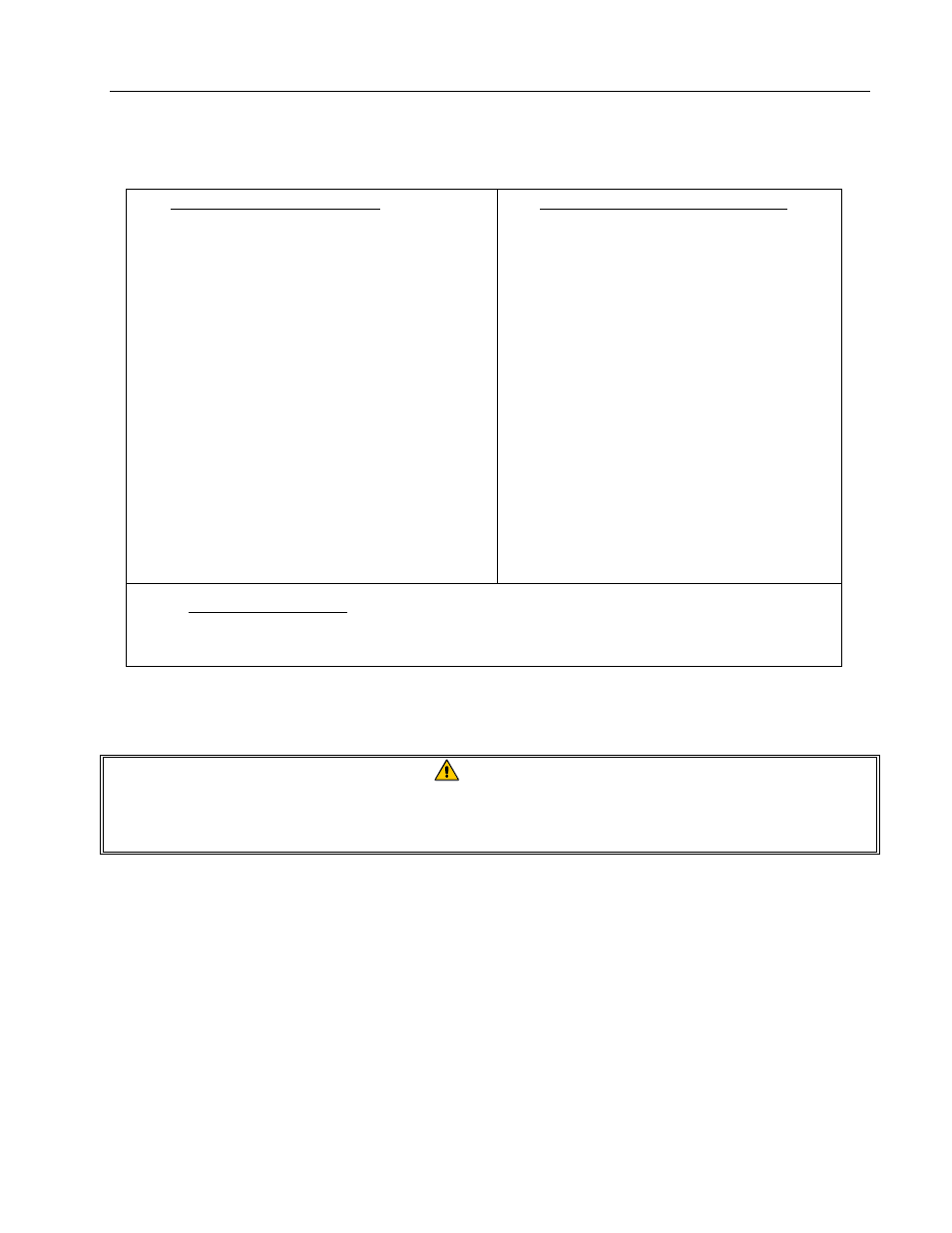

C. Installation Standards

1. U.S. installations must meet:

2. Canadian installations must meet:

American National Standard Institute

CAN 1-B149 Installation Codes

ANSI Z83.11

Canadian Gas Association

American Gas Association

55 Scarsdale Road

8501 E. Pleasant Valley Road

Don Mills, ONT, M3B 2R3

Cleveland, OH 44131

National Electrical Code

Canadian Electric Code c22.1, part 1

ANSI/NFPA #70

Canadian Standards Association

American National Standard Institute

178 Rexdale Blvd.

1430 Broadway

Rexdale, ONT, M9W 1R3

New York, NY 10018

NFPA Standards #96 and #211

National Fire Protection Association

470 Atlantic Avenue

Boston, MA 02110

3. CE/Export Standards: Fryer installation must conform with local codes, or, in the

absence of local codes, to the appropriate national or European Community (CE)

standards.

2.7 Air Supply and Ventilation

DANGER

This appliance must be installed with sufficient ventilation to prevent the occurrence

of unacceptable concentrations of substances harmful to the health of personnel in

the room in which it is installed.

Keep the area around the fryer clear to prevent obstruction of combustion and ventilation airflow as

well as for service and maintenance.

A. Do not connect this fryer to an exhaust duct.

B. Correct installation and adjustment will ensure adequate airflow to the fryer system.

C. A commercial, heavy-duty fryer must vent its combustion wastes to the outside of the building.

A deep-fat fryer must be installed under a powered exhaust hood, or an exhaust fan must be

provided in the wall above the unit, as exhaust gas temperatures are approximately 800-1000°F

(427-538°C). Check air movement during installation. Strong exhaust fans in the exhaust

hood or in the overall air conditioning system can produce slight air drafts in the room.