Calibrating the bevel angle – Festool Kapex KS 120 User Manual

Page 26

26

Kapex KS120 Miter Saw

Calibrating the Bevel Angle

Calibrating the bevel angle uses the same 4-cut method

page 24. Refer to the discussion on page 24 for an

explanation of the method.

Except for cutting tall miters, the bevel setting accuracy is

generally less critical than the miter setting accuracy. Take

care not to attempt to over-calibrate this setting.

Getting Started

You will need a piece of scrap wood that is between 4 and

4-3/4 inches on a side. The scrap does not need to be

perfectly square, but at least the first edge must be

straight. The larger the piece, the more accurate your final

measurement will be, but 4-3/4” is the maximum size that

can be cut using the Tall Miter Setting (see page 14).

The material can be anything, but Medium Density

Fiberboard (MDF) will give you the cleanest cuts, and

therefore, the easiest to measure.

►

High density plywood, such as Baltic birch, will also give

very accurate results.

►

Low-grade plywood may have rough edges, depending

on the quality, and therefore, may provide the lowest

accuracy.

►

Solid wood can also be used, but you may experience

burning on the rip-cuts if you are using a fine-tooth

blade.

You will need a ruler to measure the length of the final

offcut, and optionally, a dial caliper to accurately measure

the difference in the width of the offcut at both ends. This

width measurement is the most critical, so a dial caliper is

recommended.

It does not matter whether your measurements

are in metric units or imperial units.

Measuring the Error

Before adjusting the saw, you first need to measure

whether it is accurately calibrated to begin with. The

factory calibration threshold is ±0.5°. If you attempt to

exceed this calibration threshold, you may end up actually

making the saw less accurate.

1.

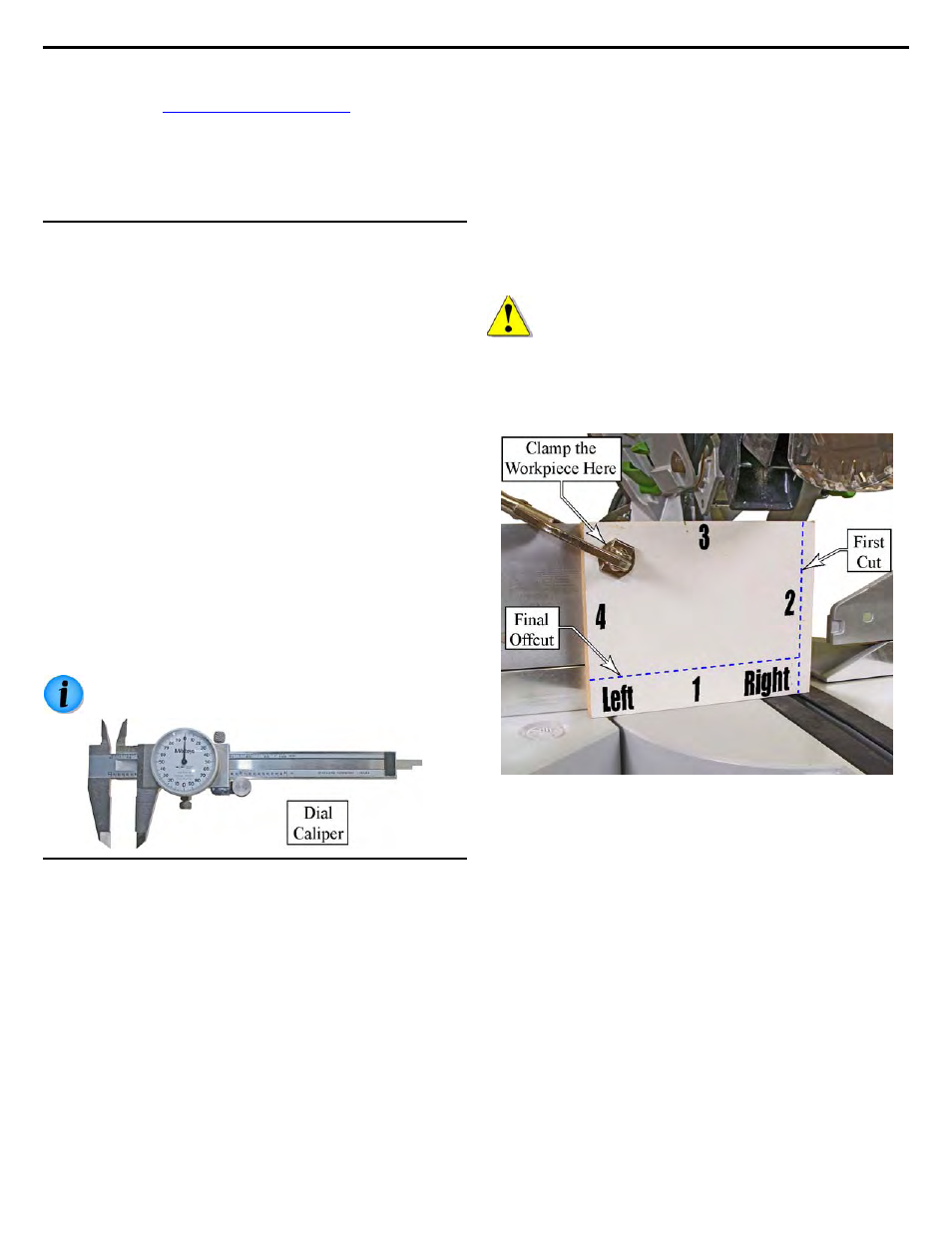

Number the sides of the scrap piece of wood from 1 to

4, starting with the best edge.

►

If you cut the wood on the left side of the blade (as

shown in this example), then number the sides in a

counterclockwise direction (as shown).

►

If you cut the wood on the right side of the blade,

then number the sides in a clockwise direction.

►

Note that this is the opposite from the miter

calibration numbering.

2.

On the #1 side, which will eventually become the final

calibration offcut, label it “Left” and “Right” as shown.

Do this regardless whether the cut is made on the left

or right side of the sawblade.

3.

Lock the saw in the Tall Miter position. Refer to page

4.

Make sure that both auxiliary fences are in place and

supporting the workpiece. Refer to page 13.

5.

Place the scrap on the saw with the number “1” facing

down against the base of the saw.

WARNING! This procedure involves cutting small

workpieces. To reduce the risk of injury, always

clamp the workpiece to the saw.

6.

Cut approximately 1/4-inch off the board, so that there

is at least a 1/8-inch offcut. This offcut ensures that

the sawblade will be stable because there is wood on

both sides of the blade during the entire cut.

7.

Rotate the board with side #2 against the base and

repeat the same cut. Note that the side previously cut

is now against the base for each of the four cuts

described below.

8.

Rotate the board to side #3 against the base and

repeat the same cut.

9.

Rotate the board to side #4 against the base, but this

time, make the cut a little wider, so that the offcut is

large enough to handle without breaking it

(approximately 1/4 to 1/2 inch wide).

10.

Discard the first three offcuts, but the fourth offcut is

the calibration offcut.