Problem probable causes corrective action – Frymaster GEN II LOVTM BIELA14 User Manual

Page 73

7-5

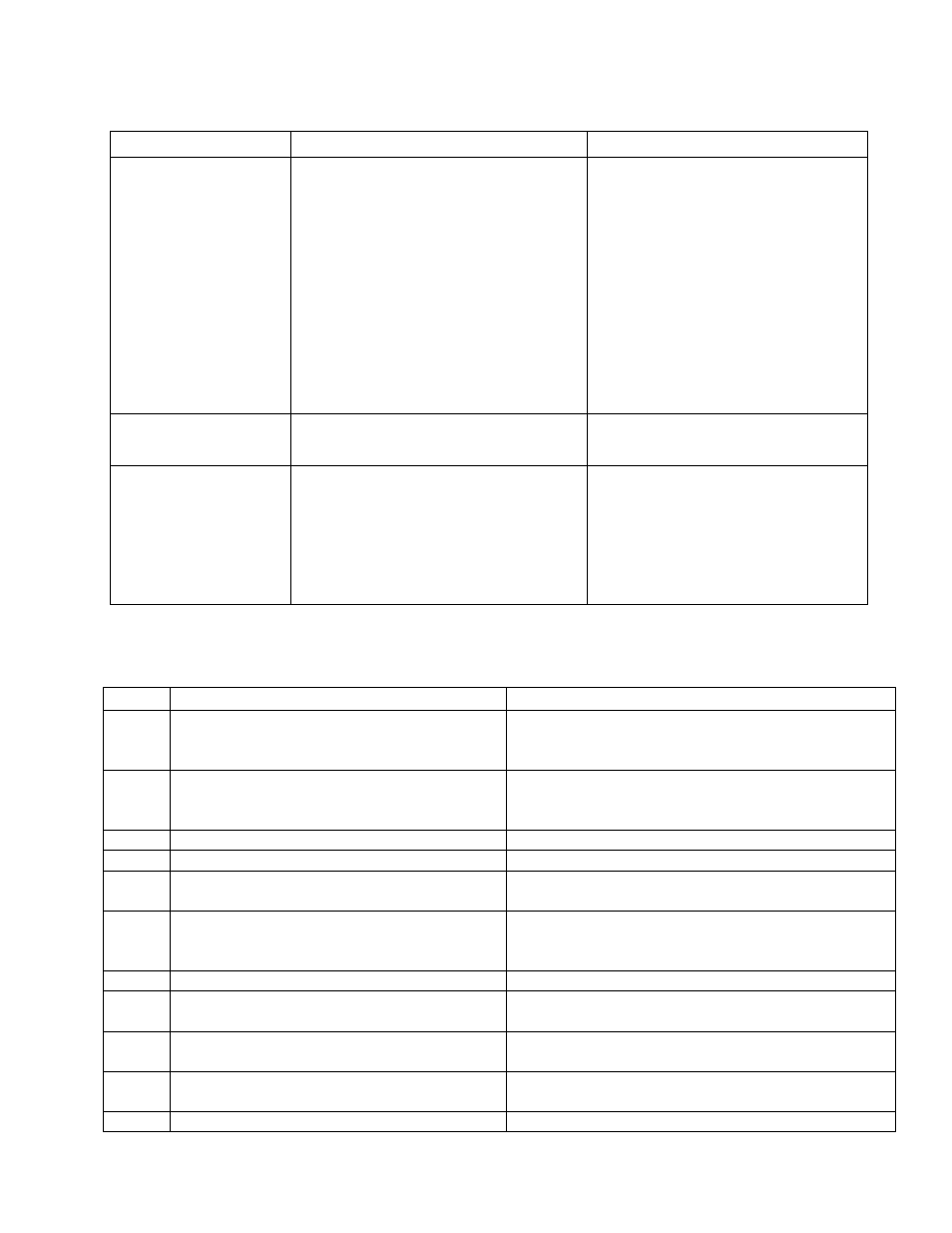

7.2.5 Bulk Oil System Problems

Problem

Probable Causes

Corrective Action

JIB won’t fill.

A.

Incorrect setup procedure.

B.

Another function is in process.

C.

Dispose valve not completely closed.

D.

Bulk oil tank is empty.

E.

Solenoid, pump or switch issue.

A.

Power cycle fryer by disconnecting

and reconnecting 5-pin control

power cord.

B.

If a filtration or any other filter

menu function is in process or

FILTER NOW? YES/NO,

CONFIRM YES/NO, or SKIM

VAT are displayed, wait until the

process is complete and try again.

C.

Ensure the dispose valve handle is

pushed fully closed.

D. Call your bulk oil provider.

E.

Call you ASA for assistance.

JIB or vat filling slow.

A.

Pump or line issues beyond the scope

of operator troubleshooting.

A.

Contact your bulk oil provider.

Frypot won’t fill.

A.

Incorrect setup procedure.

B.

Dispose valve not completely closed.

C.

Bulk oil tank is empty.

D.

RTI pump issue.

A.

Power cycle fryer by disconnecting

and reconnecting 5-pin control

power cord.

B.

Ensure the dispose valve handle is

pushed fully closed.

C. Call your bulk oil provider.

D. Call you ASA for assistance.

7.2.6 Error Log Codes

Code ERROR

MESSAGE

EXPLANATION

E01

REMOVE DISCARD (Right)

A product cook is started on the right side of a

split vat or in a full vat that has a different

setpoint other than the current vat temperature.

E02

REMOVE DISCARD (Left)

A product cook is started on the right side of a

split vat or in a full vat that has a different

setpoint other than the current vat temperature.

E03

ERROR TEMP PROBE FAILURE

TEMP Probe reading out of range

E04

HI 2 BAD

High limit reading is out of range.

E05

HOT HI 1

High limit temperature is past more than 410°F

(210°C), or in CE countries, 395°F (202°C)

E06

HEATING FAILURE

A component has failed in the high limit circuit

such as computer, interface board, contactor or

open-high limit.

E07

ERROR MIB SOFTWARE

Internal MIB software error

E08

ERROR ATO BOARD

MIB detects ATO board connection lost; ATO

board failure

E09 ERROR

PUMP

NOT

FILLING

Dirty pad and it needs changed or it was

bypassed; filter pump problem

E10

ERROR DRAIN VALVE NOT OPEN

Drain valve was trying to open and confirmation

is missing

E11

ERROR DRAIN VALVE NOT CLOSED

Drain valve was trying to close and confirmation