9 troubleshooting guides – Frymaster Dean FPHD User Manual

Page 42

HIGH EFFICIENCY DECATHLON SERIES GAS FRYERS

CHAPTER 1: SERVICE PROCEDURES

1-37

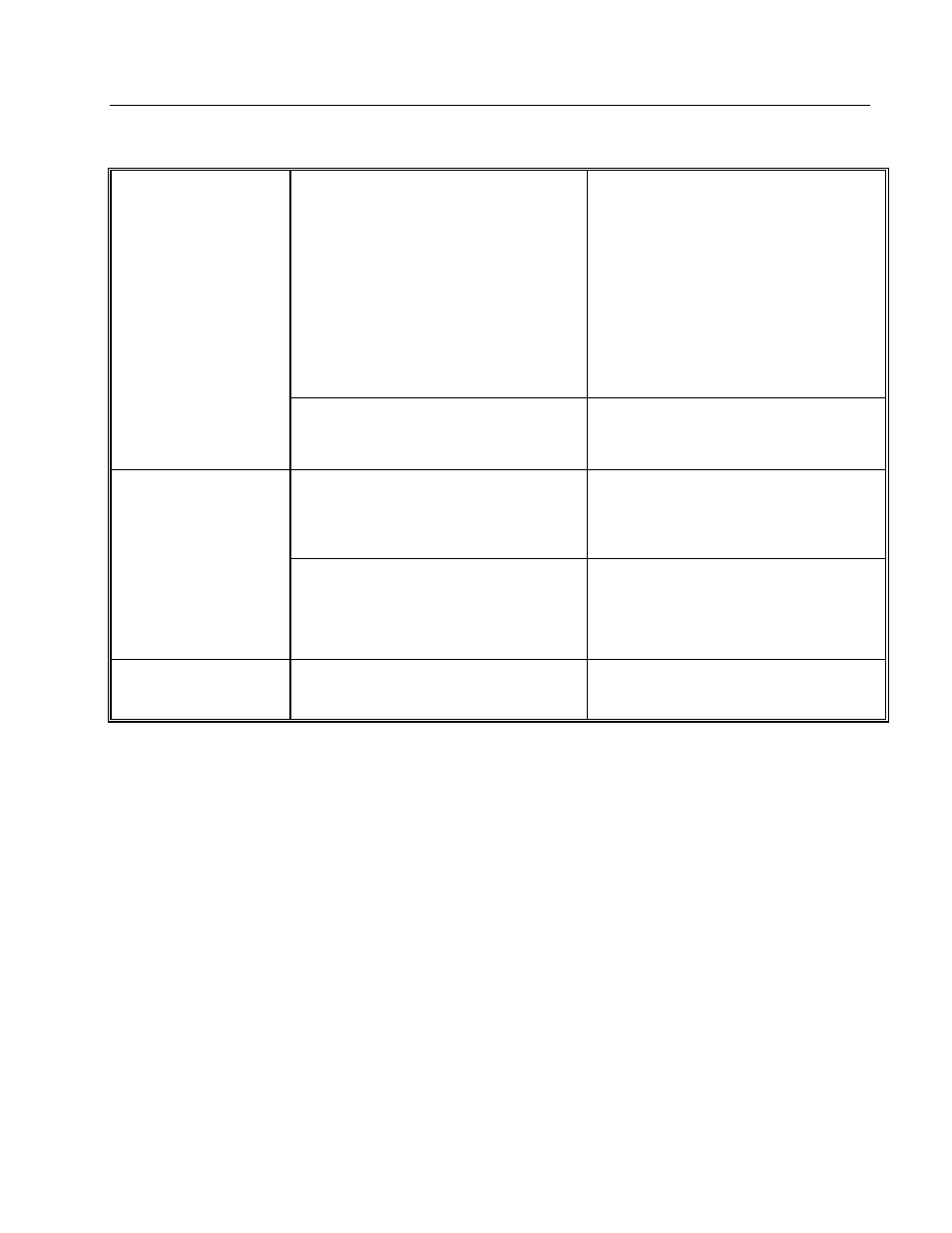

1.9 Troubleshooting

Guides

(cont.)

C. Gas valve is known to be good, but

there is not 24 VAC (120VAC on

systems so equipped) at the gas valve

terminals.

D. Inspect electronic sensor (while still in

frypot) for damage. Replace if bent,

dented, or cracked. Inspect leads for

fraying, burning, breaks, and/or kinks.

If found, remove and replace

thermostat(s). Remove leads from

terminal block, allow oil to cool 15°F

(8°C) below thermostat setting, and

check continuity. If continuity is not

"0,” then thermostat has failed.

Replace thermostat(s).

No burner flame.

E. Continuity from terminal block to gas

valve electronic/operating thermostat

wire is not "0."

E. Inspect wiring for breaks or shorts and

repair if necessary.

A. Incoming gas supply pressures are not

within range [Natural- 6-14" W.C.

(1.49-3.49 kPa); Propane- 11-14"

W.C. (2.74-3.49 kPa)]

A. Inspect gas supply to fryer. Repair

and/or replace faulty components

(defective supply shut-off valves,

incorrect piping size, etc.)

Fluctuating or erratic

lighting of burner flame. B. Air in gas supply lines (new

installation).

B. Allow unit to cycle on and off for

approximately 30 minutes to force air

from gas manifold and lines.

Electronic/operating

thermostat will not adjust

to correct temperature.

A. Electronic/operating thermostat is out

of calibration.

A. Calibrate electronic/operating

thermostat. Replace if calibration is

not possible.