Frymaster CF Series User Manual

Page 16

CF SERIES GAS FRYERS

CHAPTER 2: INSTALLATION INSTRUCTIONS

2-7

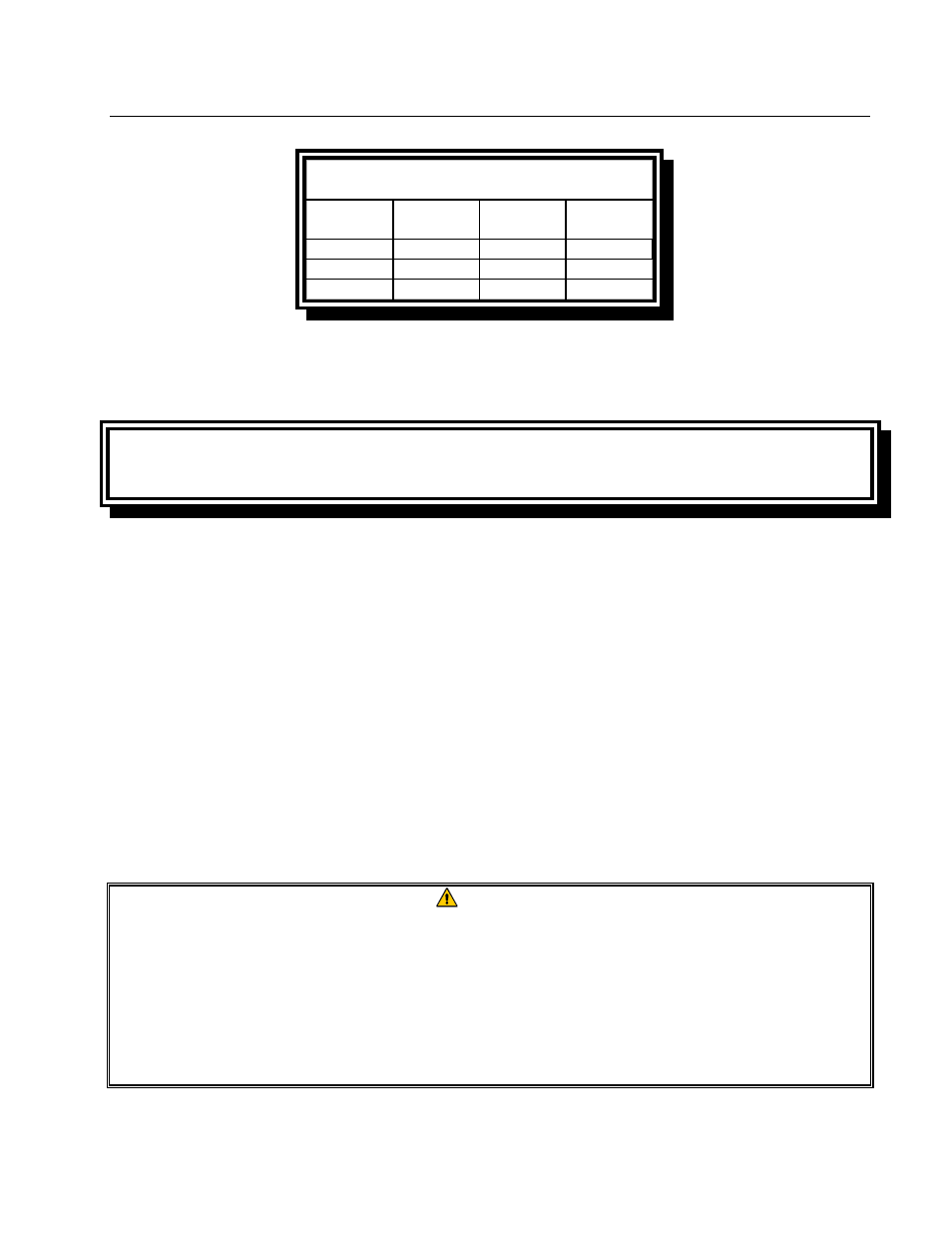

Gas Connection Pipe Sizes

[

Minimum incoming pipe size should be 1-1/2" (38 mm)]

Natural

3/4" (19 mm)

1" (25 mm)

1-1/4" (33 mm)

Propane

1/2" (13 mm)

3/4" (19 mm)

1" (25 mm)

Manufactured

1" (25 mm)

1-1/4" (33 mm) 1-1/2" (38 mm)

Gas

Single Unit

2 - 3 Units

4 or m ore

units*

* For distances of more than 20 feet (6 m) and/or more than

four fittings or elbows, increase the connection by one pipe

size.

CE Standard

CE regulations require a combustion air supply of 2m

3

/h per kW per fryer. (See rating plate affixed

to door for kW rating.)

1. Connect the quick-disconnect hose to the fryer quick-disconnect fitting under the front of the

fryer and to the building gas line.

NOTE: Some fryers are configured for a rigid connection to the gas supply line. These units are

connected to the gas supply line at the rear of the unit.

When using thread compound, use very small amounts on male threads only. Use a pipe thread

compound that is not affected by the chemical action of LP gases (Loctite PST567 sealant is one

such compound). DO NOT apply compound to the first two threads. Applying compound to the

first two threads will cause clogging of the burner orifices and control valve.

2. Open the gas-supply valve to the fryer and check all piping, fittings, and gas connections for

leaks. A soap and water solution should be used for this purpose.

DANGER

All connections must be sealed with a joint compound suitable for the gas being

used and all connections must be tested with a solution of soapy water before

lighting any pilots.

Never use matches, candles, or any other ignition source to check for leaks. If gas

odors are detected, shut off the gas supply to the appliance at the main shut-off

valve and immediately contact the local gas company or an authorized service

agency for service.