Operational checklist, General fan maintenance – MK Plastics AXTC Centrifugal Inline Fan IO&M User Manual

Page 6

M.K. Plastics Corp. Montréal, Québec www.mkplastics.com

Page. 6

Operational Checklist

Final Installation

F

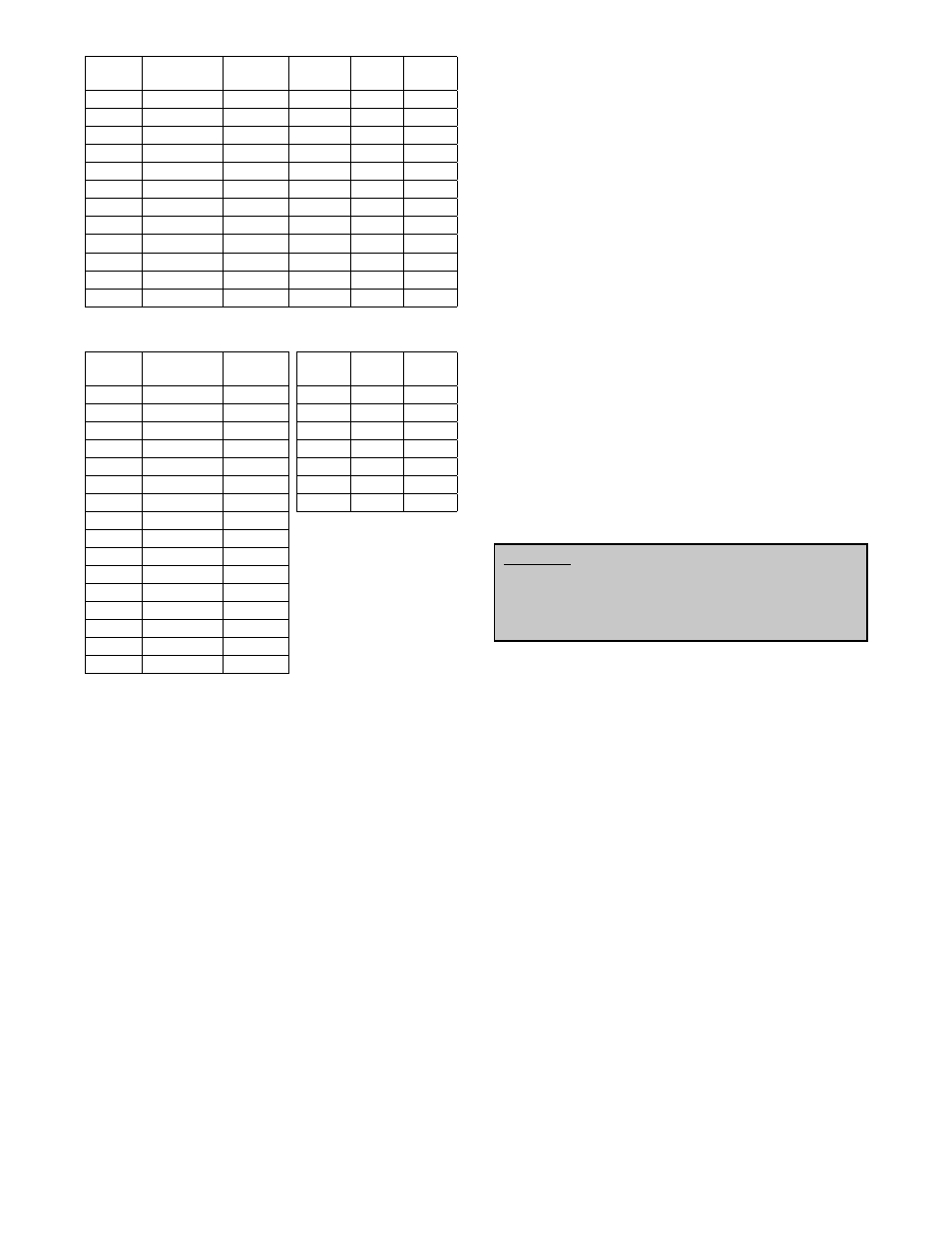

Inspect fasteners and setscrews, particularly fan

mounting and bearing fasteners, and tighten according

to the recommended torque shown in Tables 3 & 4.

F

Inspect for correct voltage with voltmeter.

F

Ensure all accessories are installed.

Pre-Start Checks

F

Shut off all primary and secondary power sources.

F

Ensure fasteners and setscrews are tightened.

F

Inspect belt tension and pulley alignment.

F

Inspect motor wiring.

F

Ensure belt touches only the pulleys.

F

Ensure fan and ductwork are clean and free of debris.

F

Inspect wheel-to-inlet clearance.

F

Close and secure all access doors.

F

Restore power to the fan.

Size

Pillow Block

Bearing

Bearing Cap

Bolt Torque

Mounting

Bolt

304 SS Bolt

Torque

316 SS Bolt

Torque

1825

NSK,SNN,1-7/16

389 in-lbs

1/2-13UNC

517 in-lbs

542 in-lbs

2225

NSK,SNN,1-7/16

389 in-lbs

1/2-13UNC

517 in-lbs

542 in-lbs

2450

NSK,SNN,1-11/16

389 in-lbs

1/2-13UNC

517 in-lbs

542 in-lbs

2700

NSK,SNN,1-11/16

389 in-lbs

1/2-13UNC

517 in-lbs

542 in-lbs

3000

NSK,SNN,2-3/16

673 in-lbs

5/8-11UNC

1110 in-lbs

1160 in-lbs

3300

NSK,SNN,2-3/16

673 in-lbs

5/8-11UNC

1110 in-lbs

1160 in-lbs

3650

NSK,SNN,2-3/16

673 in-lbs

5/8-11UNC

1110 in-lbs

1160 in-lbs

4025

NSK,SNN,2-7/16

673 in-lbs

5/8-11UNC

1110 in-lbs

1160 in-lbs

4450

NSK,SNN,2-15/16

1682 in-lbs

3/4-10UNC

1530 in-lbs

1582 in-lbs

4900

NSK,SNN,2-15/16

1682 in-lbs

3/4-10UNC

1530 in-lbs

1582 in-lbs

5425

NSK,SNN,2-15/16

1682 in-lbs

3/4-10UNC

1530 in-lbs

1582 in-lbs

6000

NSK,SNN,3

1682 in-lbs

3/4-10UNC

1530 in-lbs

1582 in-lbs

Tapered

Bushing

Cap Screw

Torque

P1-P3

5/16-18UNC

80 in-lbs

Q1-Q3

3/8-16UNC

143 in-lbs

Q1-Q3

1/4-20UNC

45.6 in-lbs

JA

No.10-24UNC

60 in-lbs

QT

1/4-20UNC

108 in-lbs

SH-SDS-SD

1/4-20UNC

108 in-lbs

SK

5/16-18UNC

180 in-lbs

SF

3/8-16UNC

360 in-lbs

E

1/2-13UNC

720 in-lbs

F

9/16-12UNC

1320 in-lbs

J

5/8-11UNC

1620 in-lbs

M

3/4-10UNC

2700 in-lbs

N

7/8-9UNC

3600 in-lbs

P

1-8UNC

5400 in-lbs

W

1-1/8-7UNC

7200 in-lbs

S

1-1/4-7UNC

9000 in-lbs

MSK

Bushing

Cap Screw

Torque

H

1/4 x 3/4

95 in-lbs

P

5/16 x1

192 in-lbs

Q

3/8 x 1-1/4

348 in-lbs

R

3/8 x 1-3/4

348 in-lbs

S

1/2 x 2-1/4

840 in-lbs

U

5/8 x 2-3/4

1680 in-lbs

W

3/4 x 3

3000 in-lbs

Table 3. - Fan Bearing Torque

Table 4. - Bushing and Pulley Torque

WARNING

Disconnect and secure to the ‘Off’ position all electri-

cal power to the fan prior to inspection and servicing.

Failure to comply with this safety precaution could

result in serious injury or death.

Start Up

Turn the fan on. In variable speed units, set the fan to its

lowest speed and inspect for the following:

F

Direction of rotation.

F

Excessive vibration.

F

Unusual noise.

F

Bearing noise.

F

Improper belt alignment or tension (listen for squeal-ing).

F

Improper motor amperage or voltage.

If a problem is discovered, immediately shut the fan off. Lock

out all electrical power and check for the cause of the trouble.

See Troubleshooting.

Inspection

Inspection of the fan should be conducted at the first

30 minute, 8 hour and 24 hour intervals of satisfactory

operation. During the inspections, stop the fan and inspect.

F

30 Minute Interval: Inspect bolts, setscrews, and motor

mounting bolts. Adjust and tighten as necessary.

F

8 Hour Interval: Inspect belt alignment and tension.

Adjust and tighten as necessary.

F

24 Hour Interval: Inspect belt tension. Adjust and tighten

as necessary.

General Fan Maintenance

Once the unit has been put into operation, a routine

maintenance schedule should be set up to accomplish the

following:

1. Lubrication of bearings and motor.

2. Wheel, housing, bolts and set screws on the entire fan

should be checked for tightness.

3. Any dirt accumulation on the wheel or in the housing

should be removed to prevent unbalance and possible

damage.

4. Isolation bases should be checked for freedom of

movement and the bolts for tightness. Springs should be

checked for breaks and fatigue. Rubber isolators should

be checked for deterioration.

5. Inspect fan impeller and housing looking for fatigue,

corrosion or wear.

6. Check V-belt drives on a regular basis for wear, tension,

alignment and dirt accumulation.