Fan bearing lubrication, Fan bearing replacement, Changing shaft speed – MK Plastics AXTC Centrifugal Inline Fan IO&M User Manual

Page 5

M.K. Plastics Corp. Montréal, Québec www.mkplastics.com

Page. 5

Fan Bearing Lubrication

Proper lubrication of the fan drive bearings helps assure

maximum bearing life. All AXTC bearings are lubricated

through a grease fitting on the outer housing and should

be lubricated by the schedule, Table 2. However, every

installation is different and the frequency of relubrication

should be adjusted accordingly.

On high moisture applications, the lubrication frequency

may need to be doubled or tripled to adequately protect the

bearings. Double the relubrication frequency on fans with

vertical shafts.

Observation of the conditions of the grease expelled from the

bearings at the time of relubrication is the best guide as to

whether regreasing intervals and amount of grease added

should be altered.

Greases are made with different bases. There are synthetic

base greases, lithium base, sodium base, etc. Avoid mixing

greases with different bases. They could be incompatible

and result in rapid deterioration or breakdown of the grease.

All bearings are filled with a lithium-based grease before

leaving the factory. When the fans are started, the bearings

may discharge excess grease through the seals for a short

period of time. Do not replace the initial discharge because

leakage will cease when the excess grease has worked out.

Sometimes the bearings have a tendency to run hotter during

this period. There is no reason for alarm unless it lasts over

48 hours or gets very hot (over 200°F). When relubricating,

use a sufficient amount of grease to purge the seals. Rotate

bearings by hand during relubrication.

Fan Bearing Replacement

Replacement of bearings requires disassembly of internal

components. For this procedure access must be available

to both the inlet/outlet ends and the lower fan casing half,

although it possible on smaller fans for bearing replacement

without access to the fan inlet. The following procedure

assumes belts have already been loosened and removed.

(Belts are removed by adjusting the motor pivot plate).

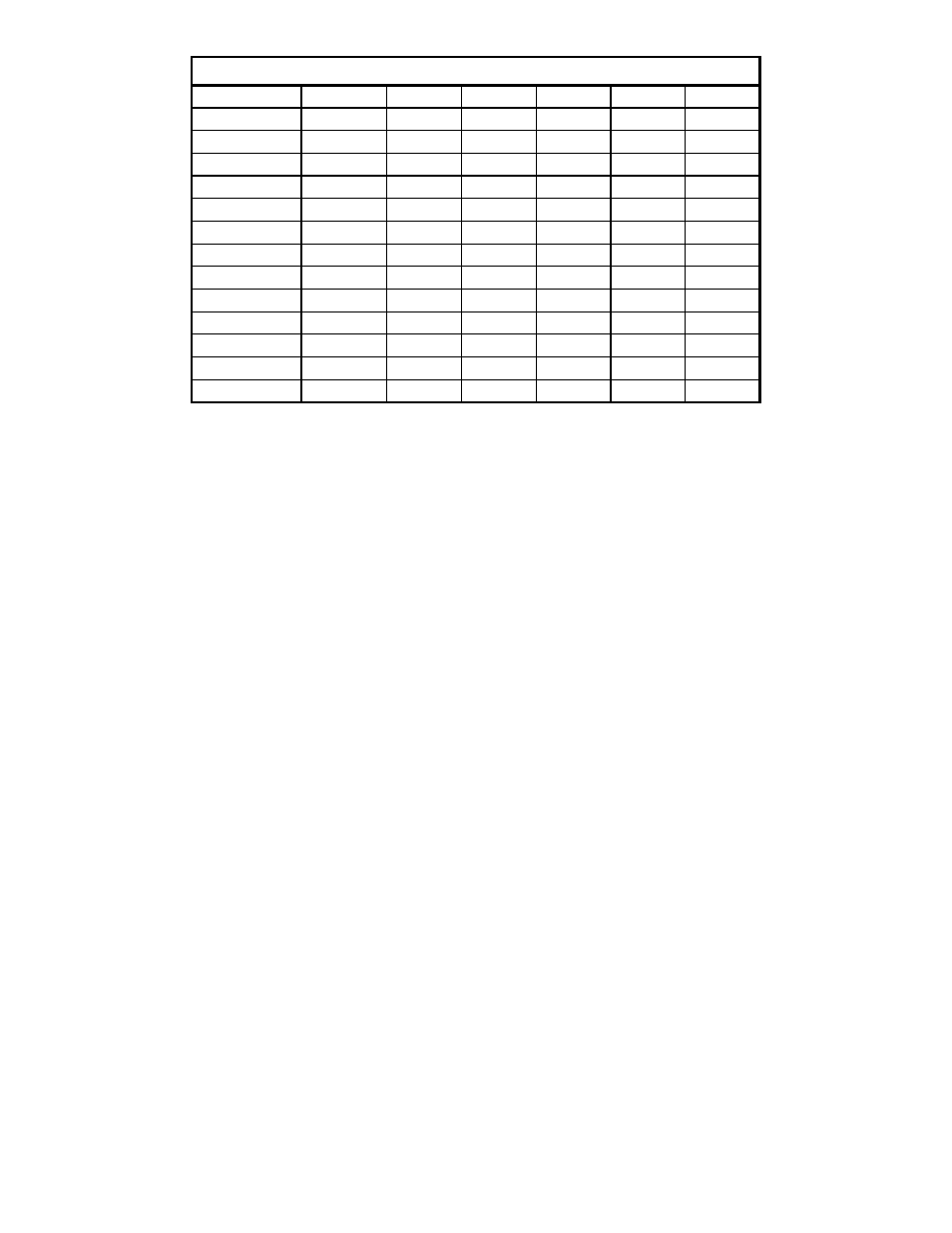

Relubrication Schedule [Months]

Speed [rpm]

500

1000

1500

2000

2500

3000

Size

1825

6

6

5

3

3

3

2225

6

6

5

3

3

-

2450

6

6

5

3

-

-

2700

6

6

5

3

-

-

3000

6

5

4

-

-

-

3300

6

5

4

-

-

-

3650

6

5

-

-

-

-

4025

5

4

-

-

-

-

4450

5

4

-

-

-

-

4900

5

4

-

-

-

-

5425

5

4

-

-

-

-

6000

4

3

-

-

-

-

Table 2. - Relubrication Schedule [Months]

AXCT fans have split-pillow block type bearings on horizontal

applications and the addition of a flange-type bearing on

vertical applications. Replacement is similar for both. Refer

to the fan parts list on Page 8.

1. Unbolt and remove the lower casing section, belt and

shaft guards.

2. Remove the inlet cone by removing the bolts around the

perimeter.

3. Remove the wheel hub cover, loosen the wheel bushing

and slide the wheel off the shaft. Note, on smaller fans

it may be possible to leave the wheel on the shaft and

remove the wheel/shaft/bearing assembly as one piece

out of the fan housing.

4. Note the location of the fan sheave on the end of the

shaft and remove the sheave.

5. Note the distance from the bearing to the end of the

shaft.

6. Unbolt both sets of bearings from the support plates and

remove the shaft/bearing assembly out the fan casing.

7. Reinstall components in reverse order of removal and

reference the Overlap, Radial Gap and Alignment

sections on Page 3. and 4.

8. Test run the fan and retighten all hardware, trim balance

if necessary.

Changing Shaft Speed

All belt driven fans with motors up to and including 5 HP

are equipped with variable pitch pulleys. To change the fan

speed, perform the following:

1. Loosen setscrew on driver (motor) pulley and remove

key, if equipped.

2. If the pulley has multiple grooves, all must be adjusted

to the same width.

3. After adjustment, inspect for proper belt tension.

4. To reduce speed, open the pulley in order that the belt

rides deeper in the groove (smaller pitch diameter).

5. To increase speed, close the pulley so that the belt rides

higher in the groove (larger pitch diameters). Make sure

the maximum fan RPM and motor HP is not reached.