Duct connections, Wheel-inlet overlap, Drive maintenance and installation – MK Plastics AXTC Centrifugal Inline Fan IO&M User Manual

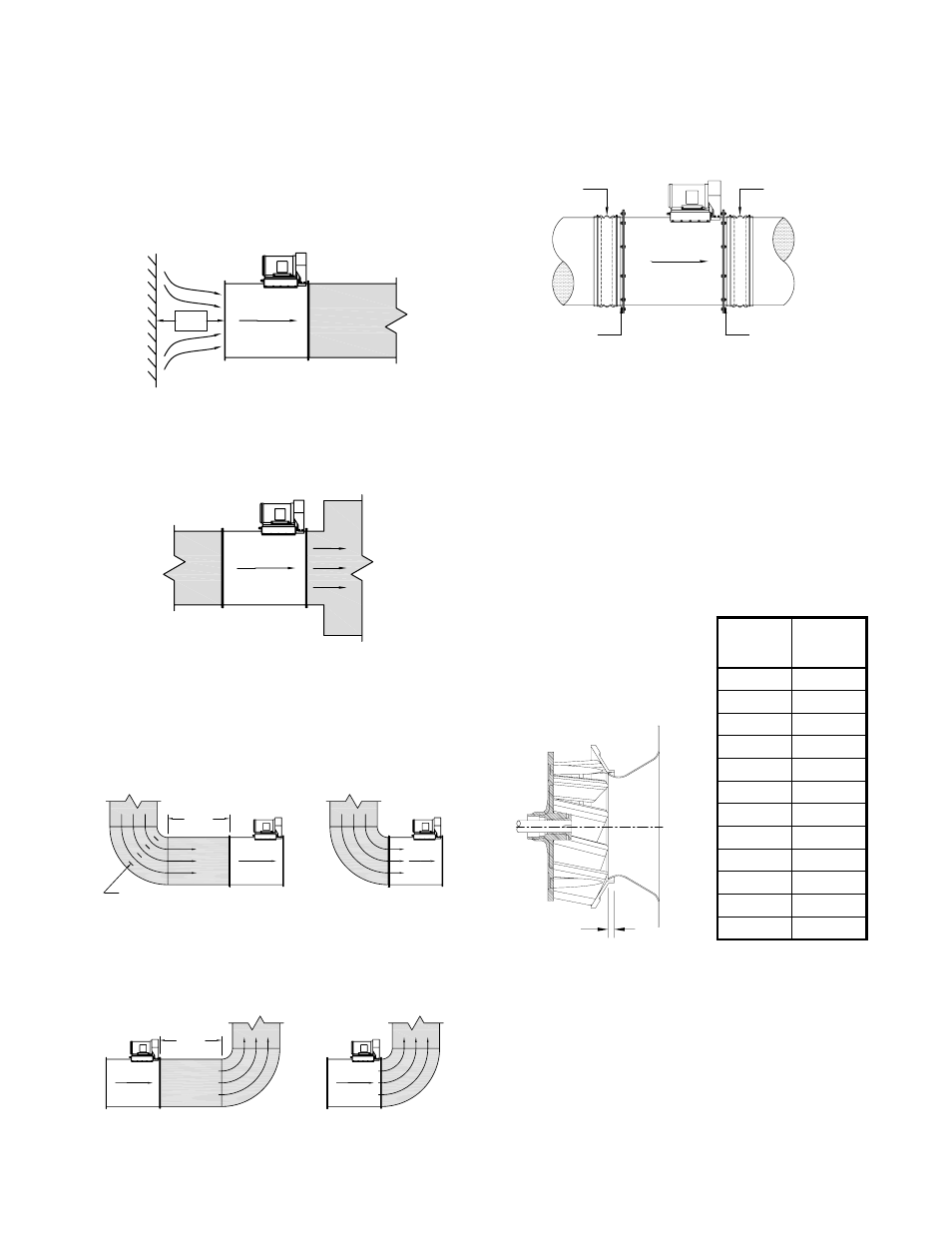

Page 3: Ducted installations, Non-ducted inlet, Free discharge, Inlet duct turns, Discharge duct turns

Duct Connections

To reduce possible vibration transmission through the

ductwork, M.K. Plastics recommends the use of flexible

connectors instead of a rigid duct connection (e.g. flange-

to-flange connection). Companion flanges are standard

accessories for flexible connection.

Wheel-Inlet Overlap

Efficient performance is achieved by having the correct wheel

to inlet overlap and uniform radial gap. This should always be

verified before initial start-up and if possible after the fan has

been in operation for 24 hours.

The overlap is adjusted by loosening the wheel hub on the

shaft and moving the wheel to the correct position - refer to

Table 1. for values. A uniform radial gap (between the edge of

wheel inlet and edge of inlet cone) is achieved by loosening

the bolts on the inlet cone and centering it on the wheel. In

both cases, a trim balance maybe required.

Drive Maintenance and Installation

V-belt drives need periodic inspection, retensioning, and

occasional belt replacement. When inspecting drives, look for

dirt buildup, burrs or obstructions that can cause premature

belt or drive replacement. If burrs are found, use fine emery

cloth or a stone to remove them. Be careful that dust does not

enter the bearings.

M.K. Plastics Corp. Montréal, Québec www.mkplastics.com

Page. 3

Ducted Installations

Efficient fan performance relies on the proper installation

of inlet and discharge ducts. Installations with poor inlet or

discharge configurations may result in reduced performance.

Make sure the following recommendations are followed.

Non-Ducted Inlet

If the AXTC has an open inlet (no duct work) that is too close

to a wall or bulkhead, this may cause performance problems.

The fan needs to have a minimum of two effective wheel

diameters away from inlet to the wall.

Free Discharge

If possible, avoid a free discharge into a plenum which could

result in lost efficiency because the effect of discharge static

regain is not allowed.

Inlet Duct Turns

Installation of a duct turn or elbow too close to the fan inlet

reduces fan performance. To achieve full fan performance,

there should be at least two effective wheel diameters

between duct turns or elbows and the fan inlet.

Discharge Duct Turns

Where possible, allow minimum two duct diameters between

duct turns or elbows and fan outlet.

Min.

2 x Dia.

Turning Vanes

Min.

2 x Dia.

Min.

2 x Dia.

Figure 4. - Open Inlet

Min.

2 x Dia.

Turning Vanes

Min.

2 x Dia.

Min.

2 x Dia.

Figure 5.

Free Discharge

Min.

2 x Dia.

Turning Vanes

Min.

2 x Dia.

Min.

2 x Dia.

Good

Poor

Figure 6 - Inlet Ducting

Min.

2 x Dia.

Turning Vanes

Min.

2 x Dia.

Min.

2 x Dia.

Good

Poor

Figure 7 - Discharge Ducting

Size

Overlap

[inches]

1825

0.75

2225

0.94

2450

1.00

2700

1.06

3000

1.31

3300

1.38

3650

1.50

4025

1.63

4450

1.81

4900

2.00

5425

2.13

6000

2.38

Overlap

Figure 9.

Wheel/Inlet Overlap

Table 1.

Wheel/Inlet Overlap

Inlet Flexible

Connector

Inlet Companion

Flange

Outlet Flexible

Connector

Outlet Companion

Flange

Inlet

Duct

Outlet

Duct

Figure 8. - Inlet/Outlet Flexible Duct Connection