Installation – Glow-worm Ultracom2 cxi User Manual

Page 29

0020085231_02 - 05/10 - Glow-worm

- 27 -

• On completion, test the gas installation for tightness using

the pressure drop method and suitable leak detection fluid,

purge in accordance with the above standard.

i

Due to the modulating operation of the boiler and the

need to check the gas inlet pressure and measure

the gas rate at maximum rate, it will be necessary to

force it to maximum.

• Activate the test mode "P.01" and set the value to 100 in

order to force the burner at P. max. See chapter "Specific

adjustment ► Appliance technical settings and parameter list

► Test modes".

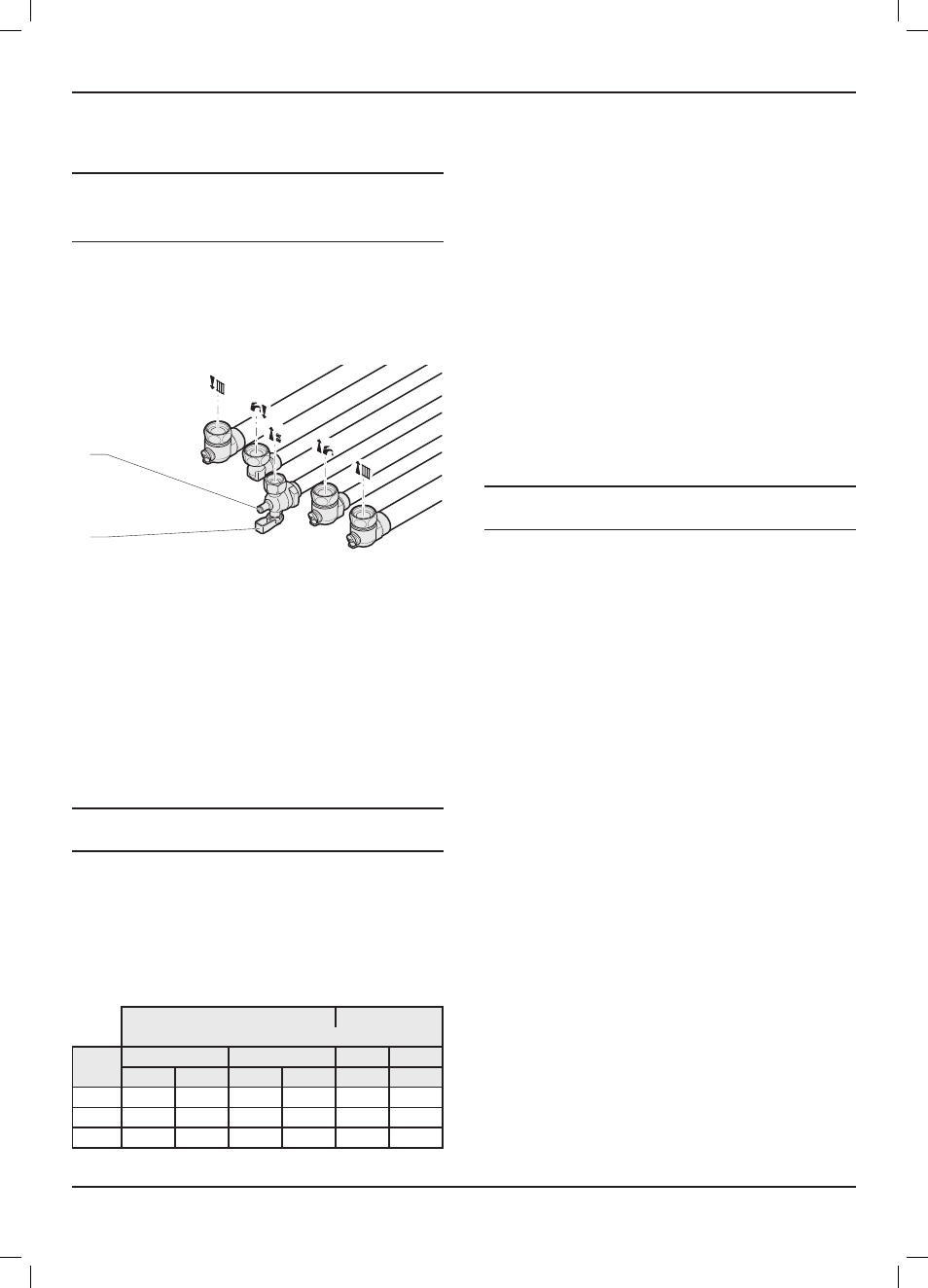

12.6.1

Operational Gas Inlet Pressure

1

2

Key

1 Gas service isolation valve

2 Test point

• With all other gas appliances operating, check the

operational supply pressure at the gas service isolation valve

test point.

The nominal supply pressure for Natural Gas (G20) is 20mbar.

The nominal supply pressure for LPG (G31) is 37mbar.

• Turn the taps and appliances off, then disconnect the

pressure gauge.

Additionally the safe nominal maximum heat input of the

appliance can be achieved at an inlet pressure down to 15mbar.

i

The burner pressure cannot be measured and is not

used to measure the gas rate.

12.6.2

Gas Rate

• Make sure that all other gas burning appliances and pilot

lights are off.

• Check the gas rate using the gas meter test dial and stop

watch, at least 10 minutes after the burner has lit, see table

below for approximate rates.

Gas rates (G20)

Gas rates (G31)

(approx) after 10 mins from cold

Model

MIN

MAX

MIN

MAX

m

3

/h

ft

3

/h

m

3

/h

ft

3

/h

kg/h

kg/h

24cxi

0.54

19.07

2.70

95.35

0.40

1.98

30cxi

0.65

22.95

3.24

114.42

0.47

2.38

35cxi

0.95

33.55

3.77

133.14

0.68

2.77

In communal or LPG installations where the gas rate cannot be

measured it is acceptable to measure the combustion rate as

described in the servicing section.

• On completion, press the "reset" button to reset the boiler.

12.7 Testing heating system

• Ensure that the external controls and programmer are calling

for heat.

• Fully open all radiator valves, see chapter "Appliance

installation

► Recommendations before installing ► Heating

circuit design".

• Activate the C.H. function on the appliance's control panel.

• Balance the radiators as required to give the required system

differential.

• Turn off all radiators that can be shut off by the user and

check to see if less than the maximum differential allowed of

20°C can be achieved across flow and return.

i

Should the appliance require adjustment refer to the

"Specific adjustment" section overleaf.

• Allow the system to reach maximum temperature then switch

off the boiler by isolating from the electrical supply.

• Drain the entire system rapidly whilst hot, using the drain

taps at all the low points of the system. Fill and vent the

system as described previously in chapter "Commissioning

► Filling the CH system (Central heating)".

• Adjust the boiler temperature controls and any system

controls to their required settings.

12.8 Testing domestic hot water system

• Open a hot-water tap.

• Check that the temperature obtained is compliant with the

setting on the appliance.

12.9 Completion

• Ensure that the magnetic lighting instruction label is placed

on the surface of the boiler casing.

GB: It is a requirement that the “Benchmark” Installation,

Commissioning and Service Record is completed and left with

the user.

IE: it is necessary to complete a “Declaration of Conformity” to

indicate compliance to I.S.813. An example of this is given in

the current edition of I.S.813.

INSTALLATION