Installation – Glow-worm Ultracom2 cxi User Manual

Page 13

0020085231_02 - 05/10 - Glow-worm

- 11 -

7.2.2

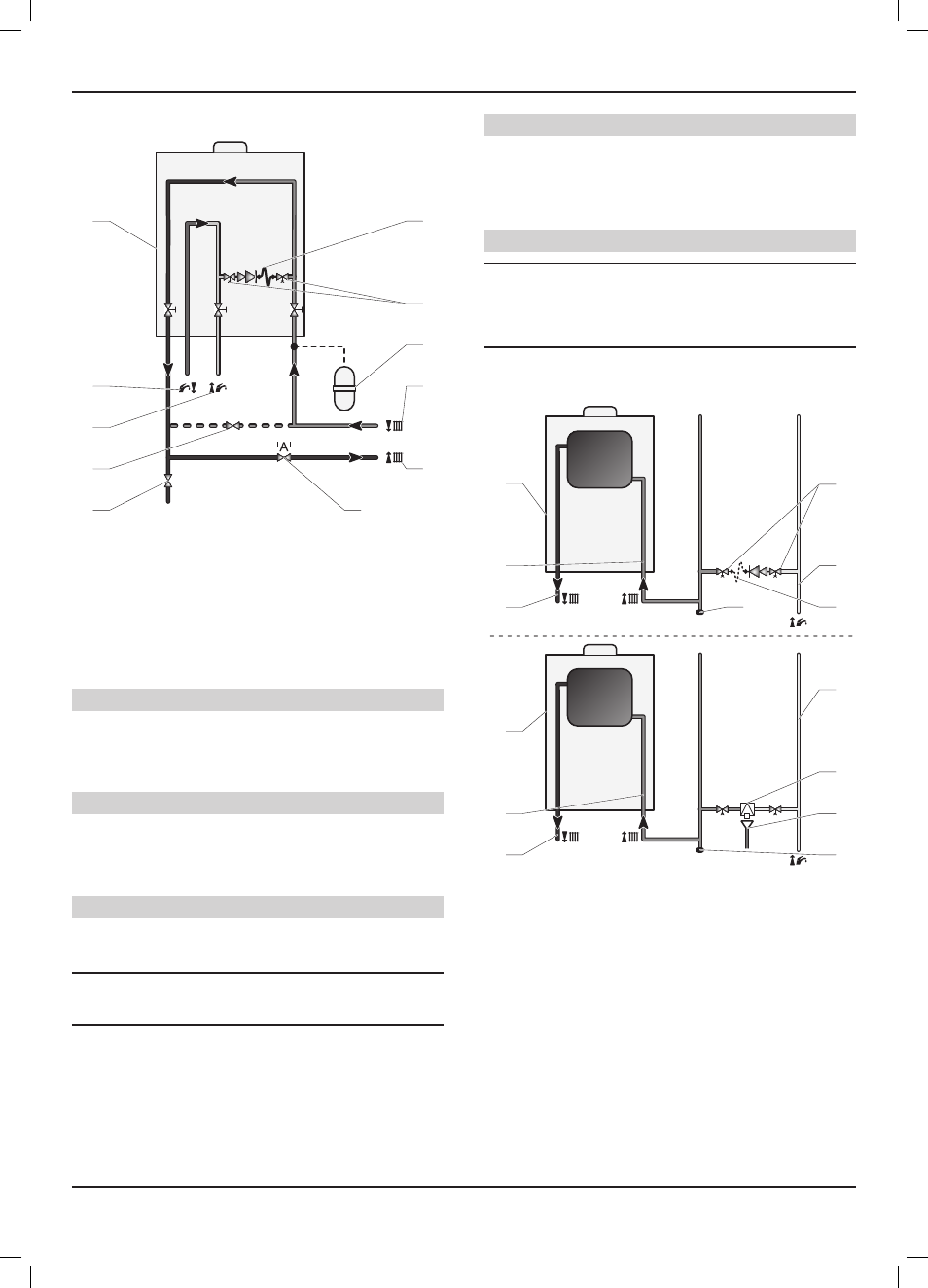

Heating circuit design

5

4

3

2

1

6

8

7

9

10

11

Key

1 Drain point

2 External bypass (if required)

3 Domestic hot water out

4 Domestic cold water supply in

5 boiler

6 filling loop - to be unlocked and disconnected after use.

7 Double check valve assembly

8 Additional expansion vessel (if required)

9 Heating return circuit

10 Heating flow circuit

General

This boiler is designed for use as part of a sealed water central

heating system with fully pumped circulation. The pump,

expansion vessel and associated safety devices are all fitted

within the boiler.

Safety valve

The safety valve is an integral part of the boiler and it cannot

be adjusted. The pipe from the safety discharge valve must

discharge safely in accordance with standards.

Expansion vessel

The boiler has an integral expansion vessel with a capacity of 8

litres (1.76 gallons), with a charge pressure of 0.75bar.

i

The heating system volume should be calculated to

ensure that the expansion vessel is suitable, it may

be necessary to add an additional vessel.

- In GB, Guidance on vessel sizing is also given in the current

issue of BS5449 and BS7074 Part 1.

- In IE, current edition of I.S.813 “Domestic Gas Installations”.

Bypass

The boiler is fitted with an automatic bypass which can be

adjusted to suit your system requirements.

• Ensure that under no circumstances does the flow rate drop

below the figure specified, refer to chapter "Technical data".

Filling the sealed system

i

The water pressure at the boiler must be at least

1.2bar to operate the filling loop. If the pressure

is less than 1.2bar an external filling loop must be

fitted. If this pressure is not available contact the

local water authority.

Suitable external filling systems are shown diagrammatically,

see diagram below.

3

2

1

3

2

1

4

8

9

7

5

7

6

5

Key

1 Heating flow circuit

2 Heating return circuit

3 boiler

4 Double check valve assembly

5 Domestic cold water supply in

6 Temporary filling loop (remove immediately after filling)

7 Drain point

8 Back flow prevention device

9 Tundish

The system should be pressurised to 0.8bar, indicated on the

digital display with no heating demand.

INSTALLATION