Maintenance, Warning, Caution – Leslie Controls NYC Heat Exchanger User Manual

Page 15

Page 15 of 25

MAINTENANCE

HEAT EXCHANGERS

(Refer to manufactures specific IOM)

(ref. Valve listing)

Shut down steam and supply water to heat exchanger by

turning off valves on the side to be flushed (59), and two

(41).

Open plugs (19) on the ends of the water pipes to the heat

exchanger.

Flush the heat exchanger per manufactures instructions.

Replace the plugs (19) after Teflon taping the threads to

insure no leakage.

Re-turn all valves to there run position.

BLEND VALVES

(Refer to manufactures specific IOM)

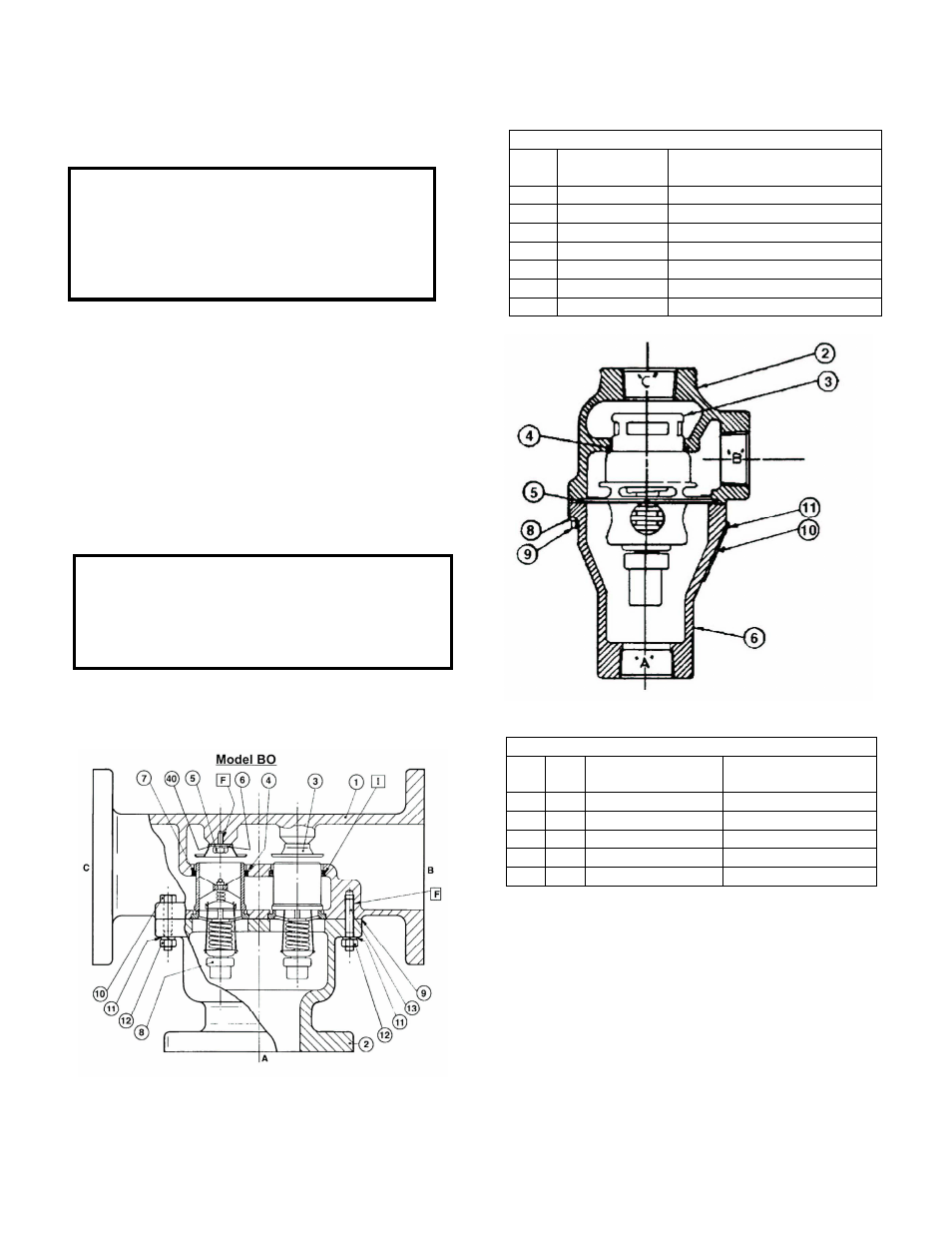

Figure 13 - MODEL B

Service Parts For Model BO

Ref

No

Part No

Description

3

9585L001

Seat, Bolted-In

4

1182

Sleeve

5

11132L050

Capscrew

6

11133

Lockwasher

7

1183

Element O-Ring, Buna-N

8

1096X(TEMP) Element Assembly

9

761

O-Ring

Figure 14 - MODEL C

Service Kit No. 9167X(Temp.) Standard Element

Ref

No

Qty Description

Part No.

3

1

Element

1125X(A83723)

4

1

O-Ring

1205

5

1

O-Ring

277L145

6

1

O-Ring

11080L001

7

1

O-Ring

11079L001

An element may be quickly checked by immersing it in an

agitated bath of water. Never use oil for checking the

element. Element number and nominal temperature setting

(last three numbers of part number) are stamped on flange

of element. At 10

o

F to 13

o

F above nominal setting ,

bypass port B should be closed.

Order new element by Part No. and Nominal Temperature

Setting, which is found on element flange. If these are not

known, send complete Model No. and Serial No. on Valve

Nameplate.

WARNING!

Warranty will be void if heat exchanger tubes are not

flushed every six months. Reports on this

maintenance by Heater Serial number must be

provided to Leslie after each flushing. These reports

are to be sent to [email protected]

CAUTION!

Do not torque the U-bolts nuts more than 10 ft-lbs.

Over tightening of the nuts can cause the U-bolts to

collapse the shell of the heat exchanger.