Industrial Injection LLY Dual CP3 User Manual

Page 4

Dual Fueler CP3 Pump Kit for LLY

Dual Fueler CP3 Pump Kit for LLY

4

5

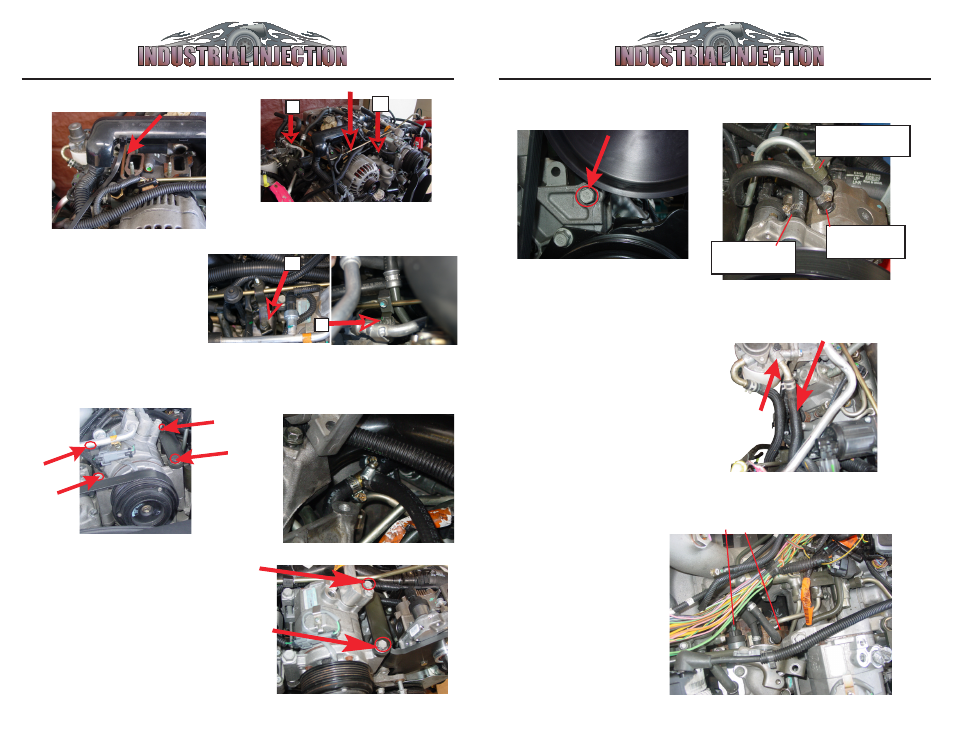

12. Attach lines by part

number as shown below:

#3

: Return

Line

#4

: High Pres-

sure Line

#2

: Inlet Fuel

Line

14. Follow flow direction arrow

A

exiting from fuel filter housing in

order to locate fuel supply hose

B.

Cut back nylon sheathing on hose

B.

Cut

stock fuel supply line

and

insert supplied

#2

1/2”x1/2”x3/8”

‘T’ connector in between 1/2” fuel

supply line, secure with

#10

1/2”

hose clamps.

A

B

9. Locate stock return line

D

from

Stock CP3 Pump. Cut rubber hose

and insert

#3

5/16”x5/16”x5/16” ‘T’

connector. Use

#11

hose clamps to

secure.

Now all 3 lines should be connected to the Dual Fueler Pump and

to the engine in the correct spots.

15. Locate Stock CP3

Pump

C

, and locate

electronic control wire

harness

E

. Unplug wire

Harness

E

.

C

E

16. Plug Wire Harness

E

into

#13

, then plug other

end of

#13

back into

Stock CP3 Pump

C

.

13. Then torque

#4 high pressure line nut

on both pump and fuel

rail ends to 30 ft lb. Re-install

Intake Manifold

.

11. Install 1 factory A/C Bolt that

you removed from top of A/C Unit

into bottom of Dual Fueler bracket.

10. Replace A/C compressor, and

reinstall Factory bolts on the left hand

side. Place

#6, (Dual Fueler Assembly

bracket with pump)

on top of the Right

A/C Compressor bolt holes on the right

hand side and use

#12 bolts

to attach

Dual Fueler Bracket Assembly to A/C

Compressor, torque 37 lb ft. Save 1

original A/C bolt for the next step.

6. Remove Intake Manifold to lay

#4 high pressure line

as shown

between intake manifold and EGR.

8. Remove

4 A/C Bolts

as

shown and set

A/C compres-

sor

to the left of the engine to

access fuel return line.

7. Install

#20 Bolt on

Brackets

to

#4 High Pres-

sure Line

as shown to

thermostat housing bolt

Q

and stud

R

next to fuel

filter bracket.

Q

R

Q

R

IMPORTANT

: If these brackets are not

installed properly high pressure line will

resonate and it will fail!