Industrial Injection LB7 Dual CP3 User Manual

Industrial Injection For the car

Dual Fueler CP3 Pump Kit for LB7

Dual Fueler CP3 Pump Kit for LB7

8

Industrial Injection

1201 S. 700W.

SLC, UT 84104

www.industrialinjection.com

Dual Fueler CP3 Pump Kit

Installation Guide for

LB7

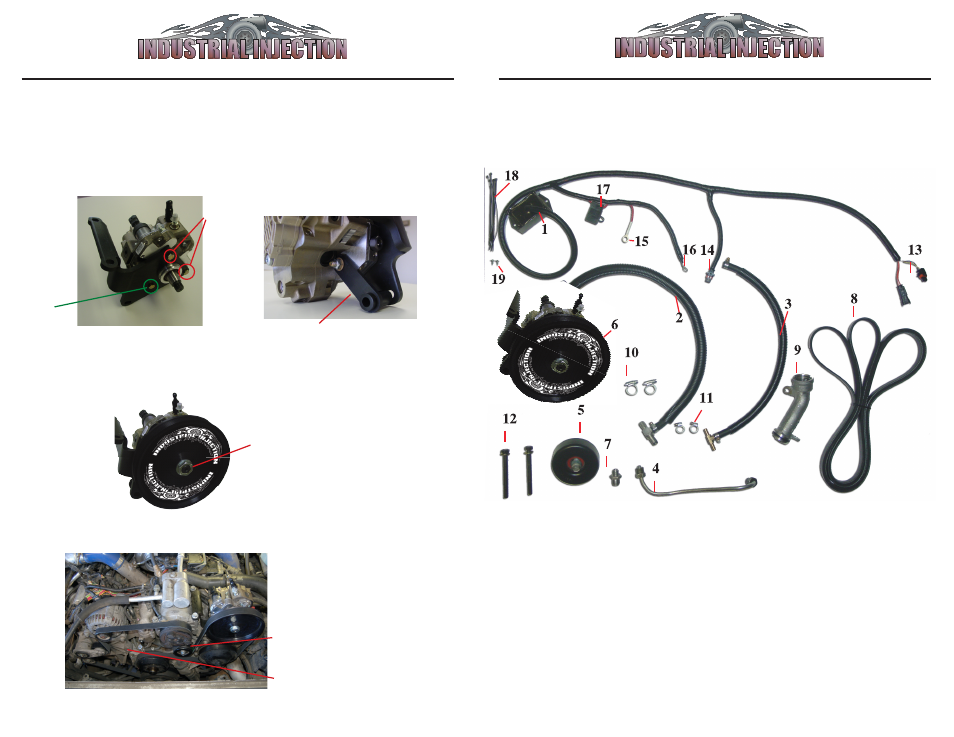

Supplied Parts:

Rev: 07/06, v1.0

1. Control Module

2. 3/8” Inlet Fuel Line with Attached 1/2” x

1/2” x 3/8” ‘T’ Connector

3. 5/16” Return Fuel Line with Attached

5/16” x 5/16” x 5/16” ‘T’ Connector

4. High Pressure Steel Fuel Supply Line

5. Idler Pully with attached parts (02-04

models only, see appendix C)

6. Assembled CP3 Pump, Wheel, and

bracket

7. Fuel Rail Fitting

8. #6 Rib Belt

Technical Support: 800-955-0476

9. Oil Filler Tube

10. 2 #6 hose Clamps

11. 6 #4 hose Clamps (4 already on hoses)

12. 2 10x1.5x100 bolts with 2 washers

13. Control Module Internal Engine Pump

connectors

14. Control Module Dual Fueler Connector

15. Control Module +12V (Red Wire)

16. Control Module Ground (Black Wire)

17. Control Module Fuse 10A

18. Control Module Harness Tie Straps

19. Control Module Mounting Screws

Please note these part numbers, they will be used in installation descriptions!

Appendix B: Fuel Pump with Bracket Assembly

3. Pully on pump by placing pully on

pump with, washer and nut, and torque

fuel injection pump drive pully nut to 52

lb ft.

1. Install Main Bracket and

insert 3 supplied bolts. Make

sure the

longer bolt L

and 2

shorter bolts S

are used as

shown.

L

S

2. Install

Smaller Support

Bracket

and secure with washer

and nut on the back of the pump

as shown. Secure other 2 bolts S

with washer and nut on the back

of the pump.

Smaller Support Bracket

drive pully nut

Appendix C: 2001 Installation

For 01 Installs, move

Idler factory idler pully

from location

i1

to loca-

tion

i2

. No other idler

pullys are required.

Route belt as shown to

the left.

i1

i2