Industrial Injection LB7 Dual CP3 User Manual

Page 3

Dual Fueler CP3 Pump Kit for LB7

Dual Fueler CP3 Pump Kit for LB7

16. Remove Fuse box Cover

F

and

place

#1

(Control Module) as shown to

the right.

#1

(photo is taken from the drivers

side of the vehicle)

18. Replace fuse box cover

F

,

taking care of not to pinch harness,

and re-assemble stock parts

G

and

H

as shown in step 15.

6

3

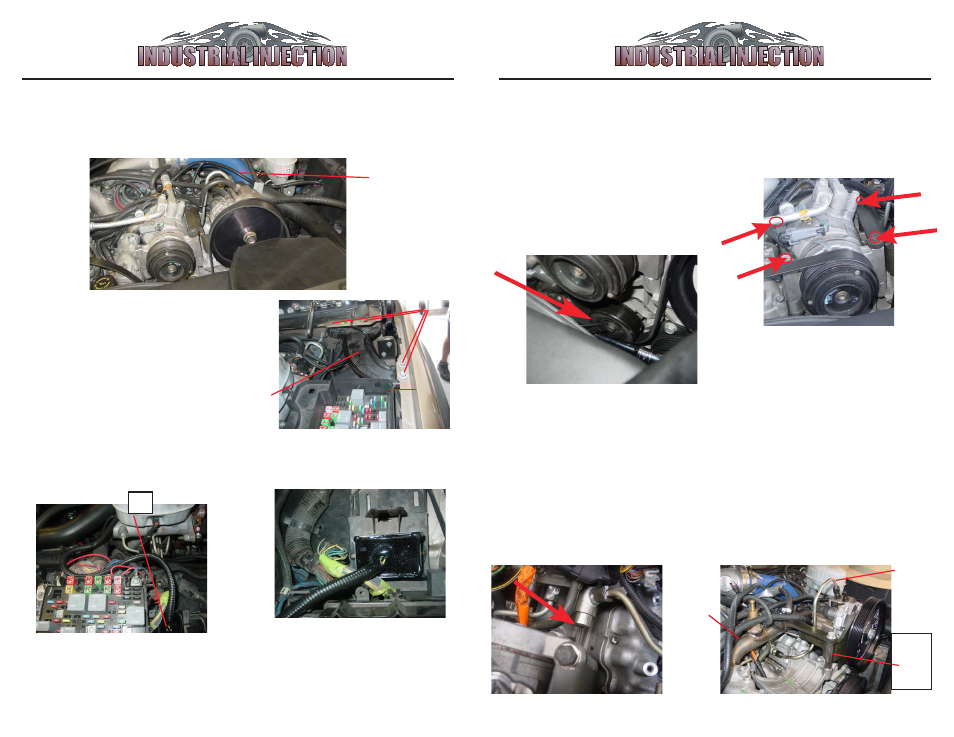

1. 02-04 Models: Remove belt and

Install

#5

Idler Pully

in existing

threaded hole on engine bracket as

shown below. Torque to 27 lb ft.

01 Models refer to appendix C.

2. Remove

4 A/C Bolts

as shown and

set

A/C compressor

to the left of the

engine to access fuel rail below.

Fig. 1

Fig. 2

3. Remove plug from end of fuel

rail with a TB50 Torx wrench or

socket and install

#7, Fuel Rail

Fitting

.

I

mportant: Early Model LB7

trucks may have a block off

plate behind torx plug fitting, if

so Remove this block off plate

and drill out to same size as sup-

plied fuel rail adapter fitting.

Fig. 3

17. Secure

#1

with

#19

screws

as shown below.

14. Route

#1

, (Control Module) Wiring from Stock CP3 Pump

C

as

shown and attach to other wiring with

#18

(tie straps). Connect

#14

to

back of Dual Fueler CP3 Pump.

15. Temporarily remove Metal Support

G

as shown by removing 4 bolts

H

and set

aside to remove fuse box cover

F

.

#1

will

be tucked inside fuse box cover

F

.

G

F

H

Wire Routing

4. Remove Water Line

W

so to

access the

#4 steel high perssure

line

when

A/C compressor

is

placed back and

Dual Fueler

is

installed.

Then attach

#4, Steel high

pressure line

, BUT DO NOT

TORQUE IT YET! Route it so it

will lay under

A/C compressor.

Ignore

this

spacer

W

#4

First: Install “Dual Fueler” bracket

and pully if not assembled on

pump. Refer to Appendix B on

page 8.