Bryant 548J User Manual

Page 33

33

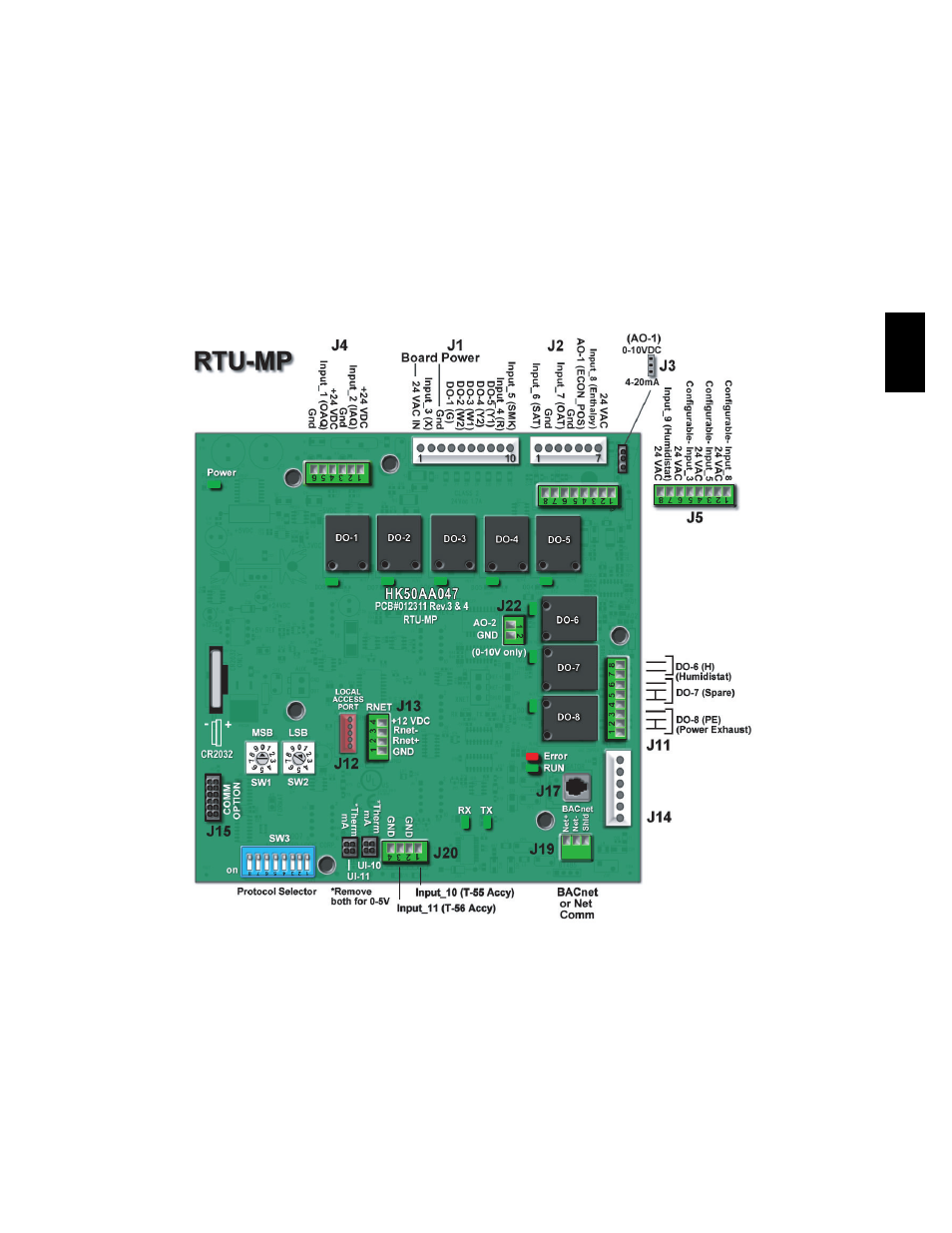

RTU--MP CONTROL SYSTEM

The RTU--MP controller, see Fig. 46, provides expanded

stand--alone operation of the HVAC system plus

connection and control through communication with

several Building Automation Systems (BAS) through

popular third--party network systems. The available

network systems are BACnet MP/TP, Modbus and

Johnson J2. Communication with LonWorks is also

possible by adding an accessory interface card to the

RTU--MP. Selection of the communication protocol and

baud rate are made at on--board DIP switches.

Bryant’s diagnostic display tools BACviewer6 Handheld

and Virtual BACview (loaded on a portable PC) must be

used with the RTU--MP controller. Connection to the

RTU--MP board is at the J12 access port, see Fig. 46.

The RTU--MP control is factory--mounted in the 548J

unit’s main control box, to the left of the CTB. See Fig. 47

(or Fig. 48). Factory wiring is completed through

harnesses connected to the CTB. Field connections for

RTU--MP sensors will be made at the Phoenix connectors

on the RTU--MP board. The factory--installed RTU--MP

control includes the supply--air temperature (SAT) sensor.

The outdoor air temperature (OAT) sensor is included in

the FIOP/accessory EconoMi$er 2 package.

Refer to Table 14, RTU--MP Controller Inputs and Outputs

for locations of all connections to the RTU--MP board.

C07129

Fig. 46 -- RTU--MP Multi--Protocol Control Board

548J