Indoor coil – Bryant 548J User Manual

Page 10

10

Avoid spraying in horizontal pattern to minimize poten-

tial for fin damage.

7. Ensure cleaner thoroughly penetrates deep into finned

areas.

8. Interior and exterior finned areas must be thoroughly

cleaned.

9. Finned surfaces should remain wet with cleaning

solution for 10 minutes.

10. Ensure surfaces are not allowed to dry before rinsing.

Reapply cleaner as needed to ensure 10--minute satur-

ation is achieved.

11. Thoroghly rinse all surfaces with low velocity clean

water using downward rinsing motion of water spray

nozzle. Protect fins from damage from the spray

nozzle.

Indoor Coil

Cleaning the Indoor Coil

1. Turn unit power off. Install lockout tag. Remove in-

door coil access panel.

2. If economizer or two--position damper is installed, re-

move economizer by disconnecting Molex plug and

removing mounting screws.

3. Slide filters out of unit.

4. Clean coil using a commercial coil cleaner or dish-

washer detergent in a pressurized spray canister. Wash

both sides of coil and flush with clean water. For best

results, back--flush toward return--air section to re-

move foreign material. Flush condensate pan after

completion.

5. Reinstall economizer and filters.

6. Reconnect wiring.

7. Replace access panels.

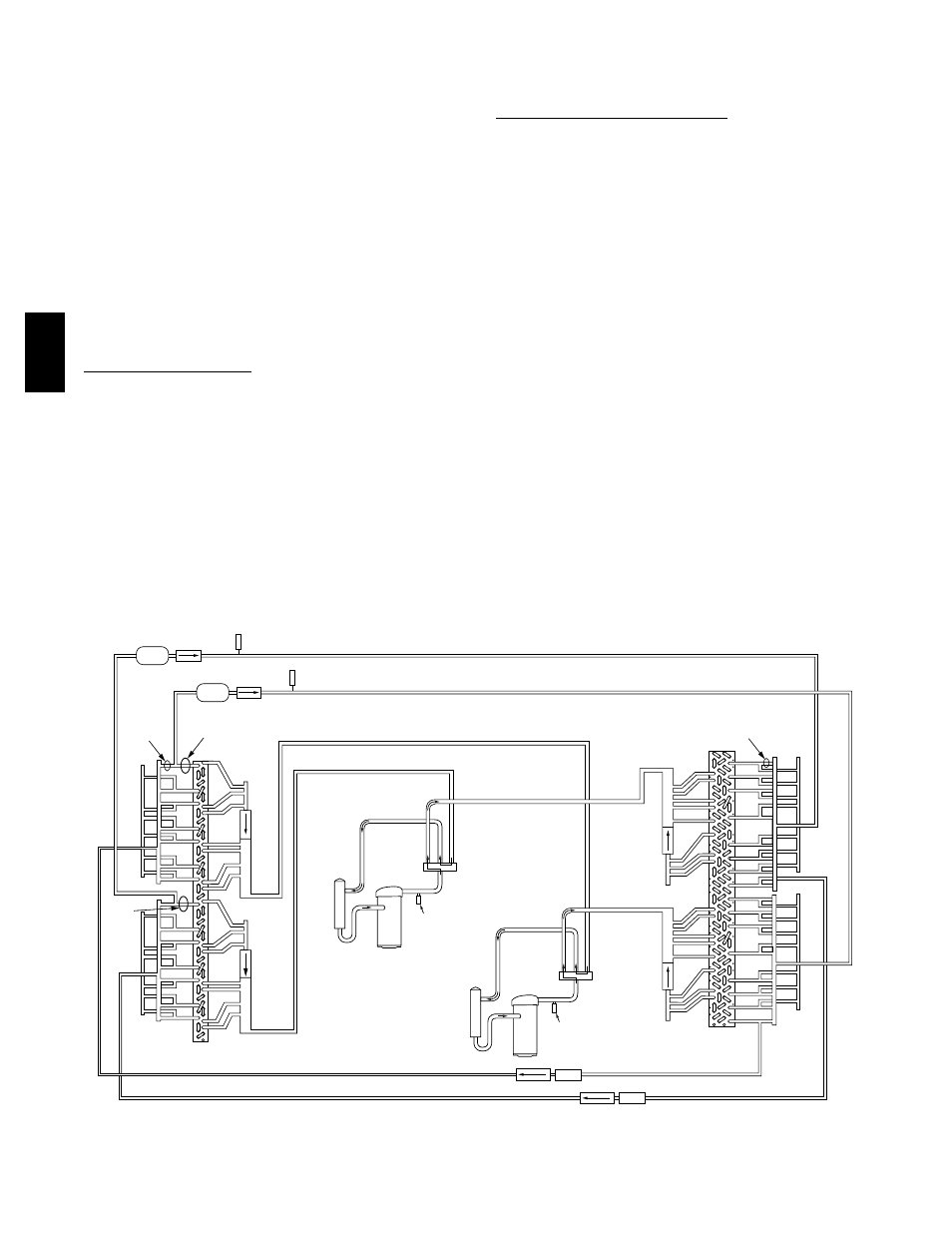

Refrigeration System Components

Each heat pump refrigeration system includes a

compressor, accumulator, reversing valve, dual--function

outdoor coil with vapor header check valve, cooling liquid

line with filter drier and check valve, dual--function

indoor coil with vapor header check valve, and heating

liquid line with check valve and strainer. Unit sizes

04A--07A have a single compressor--circuit; unit sizes

08D and 09D have two compressor--circuits. See Fig. 14

for typical unit piping schematic (unit size 09D (4--row

indoor coil) with two compressor--circuits is depicted).

Dual--function outdoor and indoor coils are designed to

provide parallel coil circuits during evaporator--function

operation

and

converging

coil

circuits

during

condenser--function operation.

Refrigerant flow metering in the evaporator--function

sequence is provided by multiple Acutrols – fixed--bore

metering devices that are located in the tee nipples

between the liquid header and the entrance to each coil

circuit. The Acutrol metering device is swaged into the

nipple tube between the liquid header end and the

side--port tube. See Fig. 15. During evaporator--function

operation, flow is straight through the nipple and into each

evaporator circuit. Flow continues through the parallel

evaporator circuits and into the vapor header.

COMPRESSOR

ACCUMULATOR

HPS

COMPRESSOR

ACCUMULATOR

HPS

Filter

Drier

2B

1B

LPS/LOC

Acutrol

DFT 1

Cooling Liquid Lines

DFT 2

2A

1A

1D

2D

Outdoor Coil

Indoor Coil

Comp 2

Comp 1

2C

1C

Strainer

Heating Mode Liquid Lines

Acutrol

C09228

Fig. 14 -- Typical Unit Piping Schematic (09D unit with 4--row indoor coil)

548J