Yokogawa EJX430B User Manual

Page 98

<11. General Specifications>

11-7

IM 01C27B01-01EN

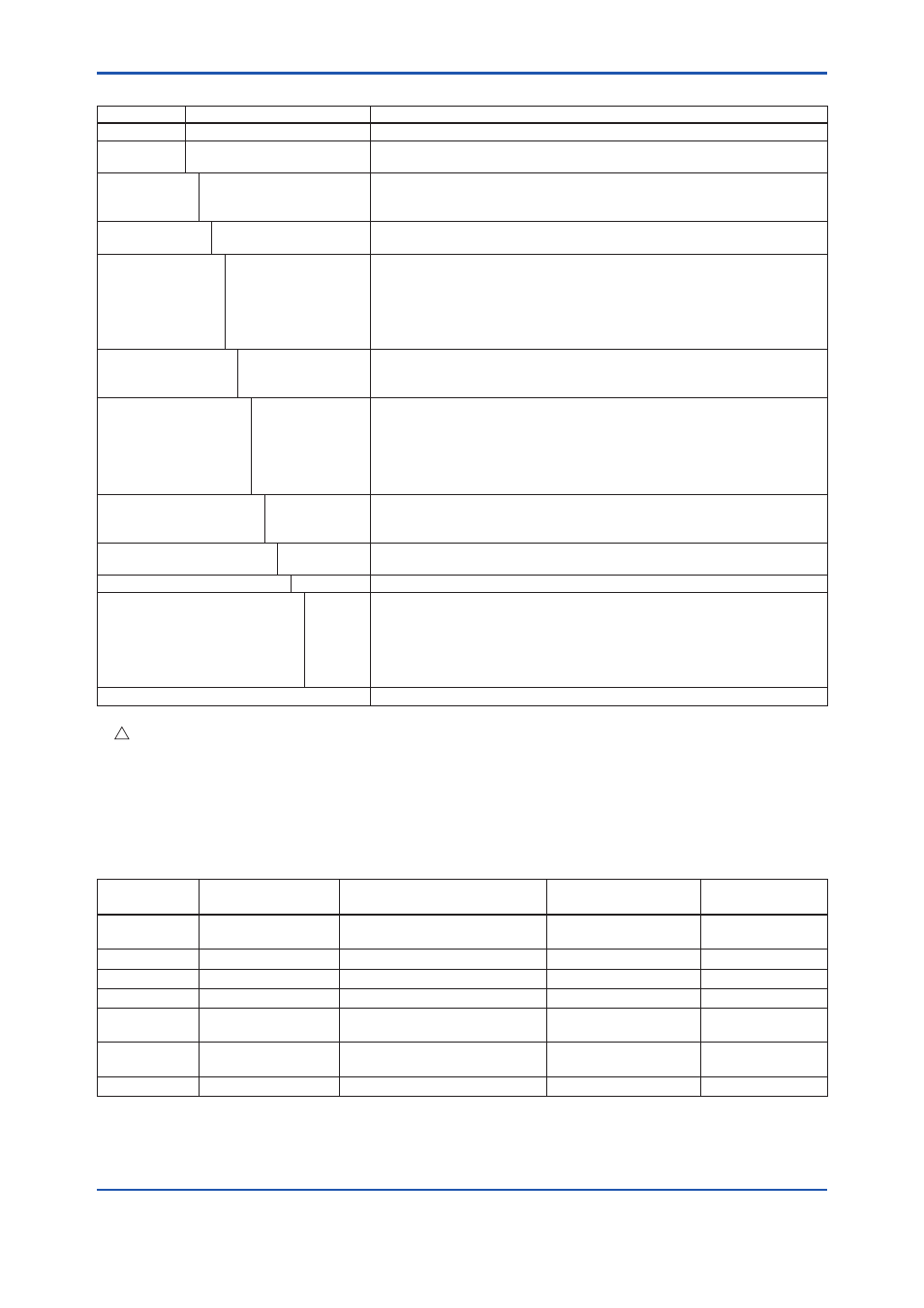

Model EJX430B

Model

Suffix Codes

Description

EJX430B

. . . . . . . . . . . . . . . . . . . . . . Gauge pressure transmitter

Output

signal

-L . . . . . . . . . . . . . . . . . . . .

Wireless communication (ISA100.11a protocol)

Measurement

span (capsule)

H. . . . . . . . . . . . . . . . . . .

A. . . . . . . . . . . . . . . . . . .

B. . . . . . . . . . . . . . . . . . .

2.5 to 500 kPa (10 to 2000 inH

2

O)

0.0175 to 3.5 MPa (2.5 to 500 psi)

0.08 to 16 MPa (12 to 2300 psi)

Wetted parts

material *

1

. . . . . . . . . . . . . . . . . Refer to “Wetted Parts Materials” Table 3.

Process

connections

►

0 . . . . . . . . . . . . . . . .

1 . . . . . . . . . . . . . . . .

2 . . . . . . . . . . . . . . . .

3 . . . . . . . . . . . . . . . .

4 . . . . . . . . . . . . . . . .

5 . . . . . . . . . . . . . . . .

without process connector (Rc1/4 female on the cover flanges)

with Rc1/4 female process connector

with Rc1/2 female process connector

with 1/4 NPT female process connector

with 1/2 NPT female process connector

without process connector (1/4 NPT female on the cover flanges)

Bolts and nuts

materia

J . . . . . . . . . . . . . .

G. . . . . . . . . . . . . .

C. . . . . . . . . . . . . .

ASTM-B7 carbon steel

316L SST stainless steel

ASTM grade 660 stainless steel

Installation

►

-3 . . . . . . . . . . .

-7 . . . . . . . . . . .

-8 . . . . . . . . . . .

-9 . . . . . . . . . . .

-B . . . . . . . . . . .

-U . . . . . . . . . . .

Vertical piping, right side high pressure, and process connection down side

Vertical piping, left side high pressure, and process connection down side

Horizontal piping and right side high pressure

Horizontal piping and left side high pressure

Bottom Process Connection, left side high pressure*

2

Universal flange*

2

Amplifier housing

7 . . . . . . . . . .

8 . . . . . . . . . .

9 . . . . . . . . . .

Cast aluminum alloy with integral antenna

Cast aluminum alloy with detachable antenna (2 dBi)

*4

Cast aluminum alloy without antenna (N connector)

*3*4

Electrical connection

J . . . . . . . . . No electrical connection, battery-powered type (battery case only; battery

cells not included)

Integral indicator

D. . . . . . .

Digital indicator

Mounting bracket

►

B. . . . .

D. . . . .

G. . . . .

K. . . . .

M . . . .

N. . . . .

304 SST 2-inch pipe mounting, flat type (for horizontal piping)

304 SST 2-inch pipe mounting, L type (for vertical piping)

304 SST 2-inch pipe mounting (for bottom process connection type)

316 SST 2-inch pipe mounting, L type (for vertical piping)

316 SST 2-inch pipe mounting (for bottom process connection type)

None

Optional Codes

/ Optional specification

The “►” marks indicate the most typical selection for each specification.

*1:

!

Users must consider the characteristics of selected wetted parts material and the influence of process fluids. The use of

inappropriate materials can result in the leakage of corrosive process fluids and cause injury to personnel and/or damage to plant

facilities. It is also possible that the diaphragm itself can be damaged and that material from the broken diaphragm and the fill fluid

can contaminate the user’s process fluids.

Be very careful with highly corrosive process fluids such as hydrochloric acid, sulfuric acid, hydrogen sulfide, sodium hypochlorite,

and high-temperature steam (150°C [302°F] or above). Contact Yokogawa for detailed information of the wetted parts material.

*2:

Applicable for Wetted parts material code S.

*3:

Order the antenna separately from accessary option.

*4: Remote antenna cables can be attached. Order separately from accessary option.

Table 3.

Wetted Parts Materials

Wetted parts

material code

Cover flange and

process connector

Capsule

Capsule gasket

Drain/Vent plug

S

#

ASTM CF-8M *

1

Hastelloy C-276 *

2

(Diaphragm)

316L SST (Others)

Teflon-coated 316L SST

316 SST

H

ASTM CF-8M *

1

Hastelloy C-276 *

2

PTFE Teflon

316 SST

M

ASTM CF-8M *

1

Monel

PTFE Teflon

316 SST

T

ASTM CF-8M *

1

Tantalum

PTFE Teflon

316 SST

A

Hastelloy C-276

equivalent *

3

Hastelloy C-276 *

2

PTFE Teflon

Hastelloy C-276 *

2

D

Hastelloy C-276

equivalent *

3

Tantalum

PTFE Teflon

Hastelloy C-276 *

2

B

Monel equivalent *

4

Monel

PTFE Teflon

Monel

*1:

Cast version of 316 SST. Equivalent to SCS14A.

*2:

Hastelloy C-276 or ASTM N10276.

*3: Indicated material is equivalent to ASTM CW-12MW.

*4: Indicated material is equivalent to ASTM M35-2.

The ‘#’marks indicate the construction materials conform to NACE material recommendations per MR01-75. For the use of 316 SST

material, there may be certain limitations for pressure and temperature. Please refer to NACE standards for details.