Optional specifications – Yokogawa EJX430B User Manual

Page 100

<11. General Specifications>

11-9

IM 01C27B01-01EN

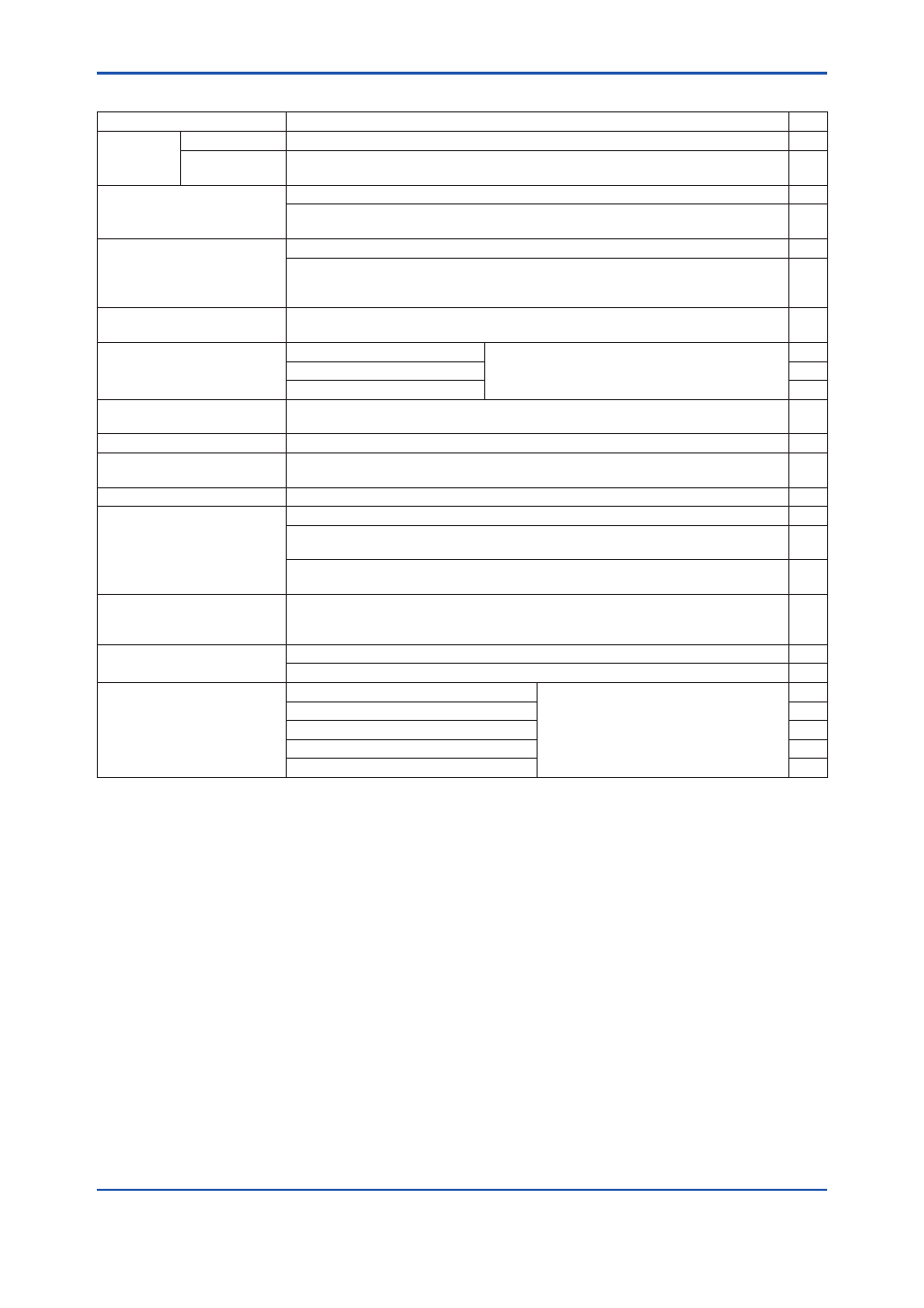

OPTIONAL SPECIFICATIONS

Item

Description

Code

Painting

Color change

Amplifier cover only

P

Coating

change

Anti-corrosion coating

*1

X2

Oil-prohibited use

*2

Degrease cleansing treatment

K1

Degrease cleansing treatment and with fluorinated oilfilled capsule.

Operating temperature -20 to 80°C ( -4 to 176°F)

K2

Oil-prohibited use

with dehydrating treatment

*2

Degrease cleansing treatment and dehydrating treatment

K5

Degrease cleansing treatment and dehydrating treatment with fluorinated oilfilled

capsule.

Operating temperature -20 to 80°C ( -4 to 176°F)

K6

Capsule fill fluid

Fluorinated oil filled in capsule

Operating temperature -20 to 80°C ( -4 to 176°F)

K3

Calibration units

*3

P calibration (psi unit)

(See Table for Span and Range Limits.)

D1

bar calibration (bar unit)

D3

M calibration (kgf/cm

2

unit)

D4

Long vent

*4

Total length: 119 mm (standard: 34 mm); Total length when combining with option

code K1, K2, K5, and K6: 130 mm. Material: 316 SST

U1

Gold-plated capsule gasket

*5

Gold-plated 316L SST capsule gasket. Without drain and vent plugs.

GS

Gold-plated diaphragm*

6

Inside of isolating diaphragms (fill fluid side) are gold plated, effective for hydrogen

permeation.

A1

130 Pa abs calibration*

7

Minimum input puressure at calibration testing: 130 Pa abs (1 mmHg abs)

S1

Body option

*8

Without drain and vent plugs.

N1

N1 and Process connection, based on IEC61518 with female thread on both sides

of cover flange, with blind kidney flanges on back.

N2

N2 and Material certificate for cover flange, diaphragm, capsule body, and blind

kidney flange.

N3

European Pressure

Directive

*9

PED 97/23/EC

Category III, Module H, Type of Equipment: Pressure Accessory-Vessel,

Type of Fluid: Liquid and Gas, Group of Fluid: 1 and 2.

PE3

Material certificate

*10

Cover flange

*11

M01

Cover flange, Process connector

*12

M11

Pressure test/

Leak test certificate

Test Pressure: 16 MPa (2300 psi)*

13

Nitrogen(N

2

) Gas

*18

Retention time: one minute

T12

Test Pressure: 25 MPa (3600 psi)*

14

T13

Test Pressure: 3.5 MPa (500 psi)*

15

T01

Test Pressure: 500 kPa (2000 inH

2

O)*

16

T11

Test Pressure: 50 kPa (200 inH

2

O)*

17

T04

*1:

Not applicable with color change option.

*2:

Applicable for Wetted parts material code S, H, M, and T.

*3:

The unit of MWP (Max. working pressure) on the name plate of the housing is the same unit as specified by Option code D1, D3,

and D4.

*4:

Applicable for vertical impulse piping type (Installation code 7) and Wetted parts material code S, H, M, and T.

*5:

Applicable for wetted parts material code S; process connection code 0 and 5; and installation code 8 and 9. Not applicable for

option code U1, N2, N3 and M11. No PTFE is used for wetted parts.

*6:

Applicable for wetted parts material code S.

Overpressure effects for EJX110B M, H, and V capsules: ±0.06% of URL.

*7:

Applicable only for EJX310B M and A capsules whose upper range value is set as smaller than 53.3 kPa abs.

*8:

Applicable for Wetted parts material code S, H, M, and T; Process connection code 3, 4, and 5; Installation code 9; and Mounting

bracket code N. Process connection faces on the other side of zero adjustment screw.

*9:

Applicable for M, H and V capsules of EJX110B with wetted parts material code S.

*10: Material traceability certification, per EN 10204 3.1B.

*11: Applicable for Process connections code 0 and 5.

*12: Applicable for Process connections code 1, 2, 3, and 4.

*13: Applicable for Capsule code L of EJX110B, Capsule code B of EJX430B and EJX310B, and all the capsules of EJX110B with

wetted parts maerial code H, M, T, A, D, and B.

*14: Applicable for Capsule code M, H, and V of EJX110B with wetted parts material code S.

*15: Applicable for Capsule code A of EJX430B and EJX310B.

*16: Applicable for Capsule code H of EJX430B.

*17: Applicable for Capsule code L and M of EJX310B.

*18: Pure nitrogen gas is used for oil-prohibited use (Option code K1, K2, K5, and K6).