Aaonaire, Heat wheel, Cleaning – AAON M1-011 User Manual

Page 34

34

11. AAONAIRE

®

Heat Wheel

The AAONAIRE

®

Heat Wheel is a “total energy”

recovery wheel, which means that it can transfer both

sensible and latent energy, that is, heat and moisture,

from one air stream to another. The heat wheel is a

disc composed of spirally wound desiccant matrix

material. The wheel is divided across the center when

installed, and rotated by an electric motor at up to 60

RPM so that one half of the matrix material is exposed

at one moment to the exhaust air stream, and at the

next moment to the ventilation supply air stream. With

a heat wheel, efficiencies of 70 to 85% are achievable

for both sensible and latent energy transfer.

Figure 11 below shows the basics of a heat wheel.

For installation, maintenance, performance, or other

information, consult the AAONAIRE

®

Setup

Information booklet that came with your AAONAIRE

®

heat wheel.

Cleaning

The need for cleaning of the heat wheel will be

determined by the operating schedule, climate, and

regular contaminants of the conditioned space. The

AAONAIRE

®

Heat Wheel is “self-cleaning” in that the

smallest particles will pass through, and larger

particles will land on the wheel surface, and will then

be blown clear as the wheel rotates into the opposite

direction of laminar flow. The primary cleaning need

will be to remove oil based aerosols that have

condensed on energy transfer surfaces. These oily

films can clog micron sized pores in the desiccant

material reducing the wheel’s efficiency. It can take

several years in a reasonably clean environment such

as a school, or an office building, for measurable

efficiency loss to occur. Dirtier air, such as that from a

kitchen, industrial or machine shop, or a smoke filled

room in a bar, will reduce efficiency in a much shorter

period of time.

To clean the wheel, remove the segments from the

wheel frame, and brush foreign material from the face.

Soak the segments in a non-acid based coil cleaner,

or another alkaline detergent, and warm water.

Massaging the matrix with your hands will increase the

cleaning action. Rinse well, and shake excess water

away before reinstalling. For applications where

frequent cleaning is required, it is advisable to keep a

second set of wheel segments on hand. While a set is

soaking, or being cleaned, the spare set can be

replaced in the wheel.

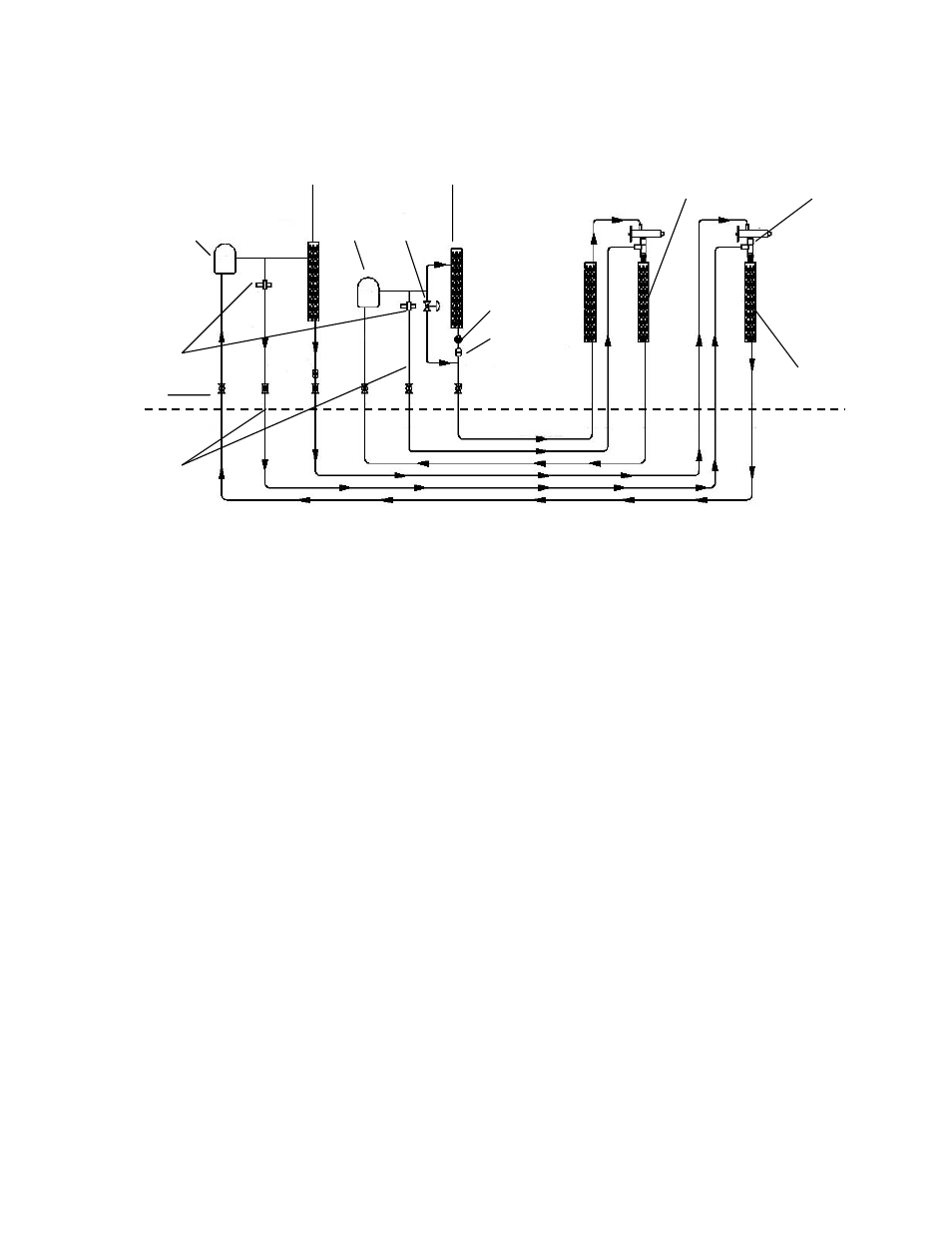

HGBP line connects to

ASC fitting between

TXV and distributor

HGBP

Valves

2

nd

Stage

Comp.

HGBP Lines

Factory Piping

Field Piping

Figure 10.2, HGRH with External HGBP Piping

TXV TXV

1

st

Stage

Condenser Coil

2

nd

Stage

Condenser Coil

1

st

Stage

Comp.

Reheat Coil

1

st

Stage

Evaporator Coil

2

nd

Stage

Evaporator Coil

HGRH

Valve

Check Valve

Filter Drier

Isolation

Valves

Filter

Drier