Valve switching – Valco electronic Valve Oven User Manual

Page 44

Chapter 4

Troubleshooting

44

Refer to the TRACE operations manual, Chapter 4, Gases and Controls, for leak

test suggestions and the necessary hardware required to pressure check a

plumbing system.

Valve Switching

Valco valves contain a rotor that is turned by the actuator. This rotor channels the

gas between the various ports of the valve. If the rotor is not being switched

properly, a flow path may be partially or fully blocked, or leaks may occur

between valve ports.

Each valve contains a mechanical stop that should reach an extreme when the

valve is rotated in the clockwise or counterclockwise direction. Close inspection

of the valve will indicate if the valve is being switched to its limits, Figure 2-4.

Actuator pressure should be 420 Kpa (60psig) to 630 Kpa (90 psig).

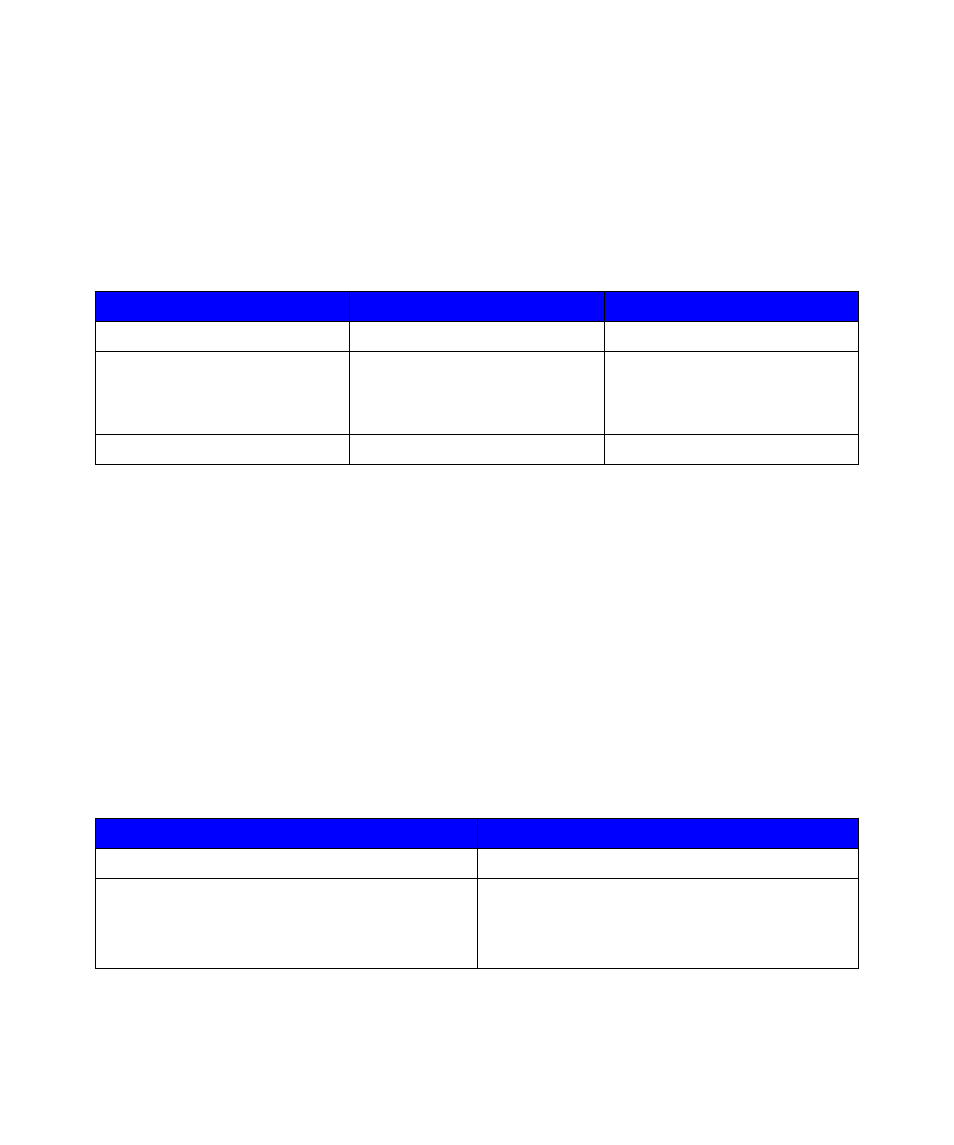

Table 4-1. Leak Testing for Valves

Symptom

Cause

Remedy

Valve leaking between ports

Defective rotor

Replace rotor or valve

Valve leaking around rotor

Valve rotor not seating

properly

Rotor Defective

Tighten rotor

Replace Rotor in valve

Leaking out valve ports

Ferrule not seating

Replace ferrule

Table 4-2. Causes and Remedies for Improper Valve Switching

Cause

Remedy

Low actuator line pressure

Increase line pressure

Solenoid not actuating

Verify timed event is set correctly

Check voltage at solenoid

Replace defective solenoid