Closed loop control system, Process desired speed setting, The actual speed is calculated from – Motorola M68HC08 User Manual

Page 81: Processs speed control

Software Design

Data Flow

DRM028 — Rev 0

Designer Reference Manual

MOTOROLA

Software Design

81

5.3.6 Process Commutation Time Calculation, Corrective Calculation 1, Corrective

Calculation 2

These processes provide calculations of commutation time intervals

(periods) (Per_ZCros, Per_ZCrosFlt), from captured time (T_Cmt

,

T_ZCros, T_ZCros0), and sets Timer 2 with variable T2. These

calculations are described in

3.3.1.5 Starting — Commutation Time

3.3.1.3 Running — Commutation Time Calculation

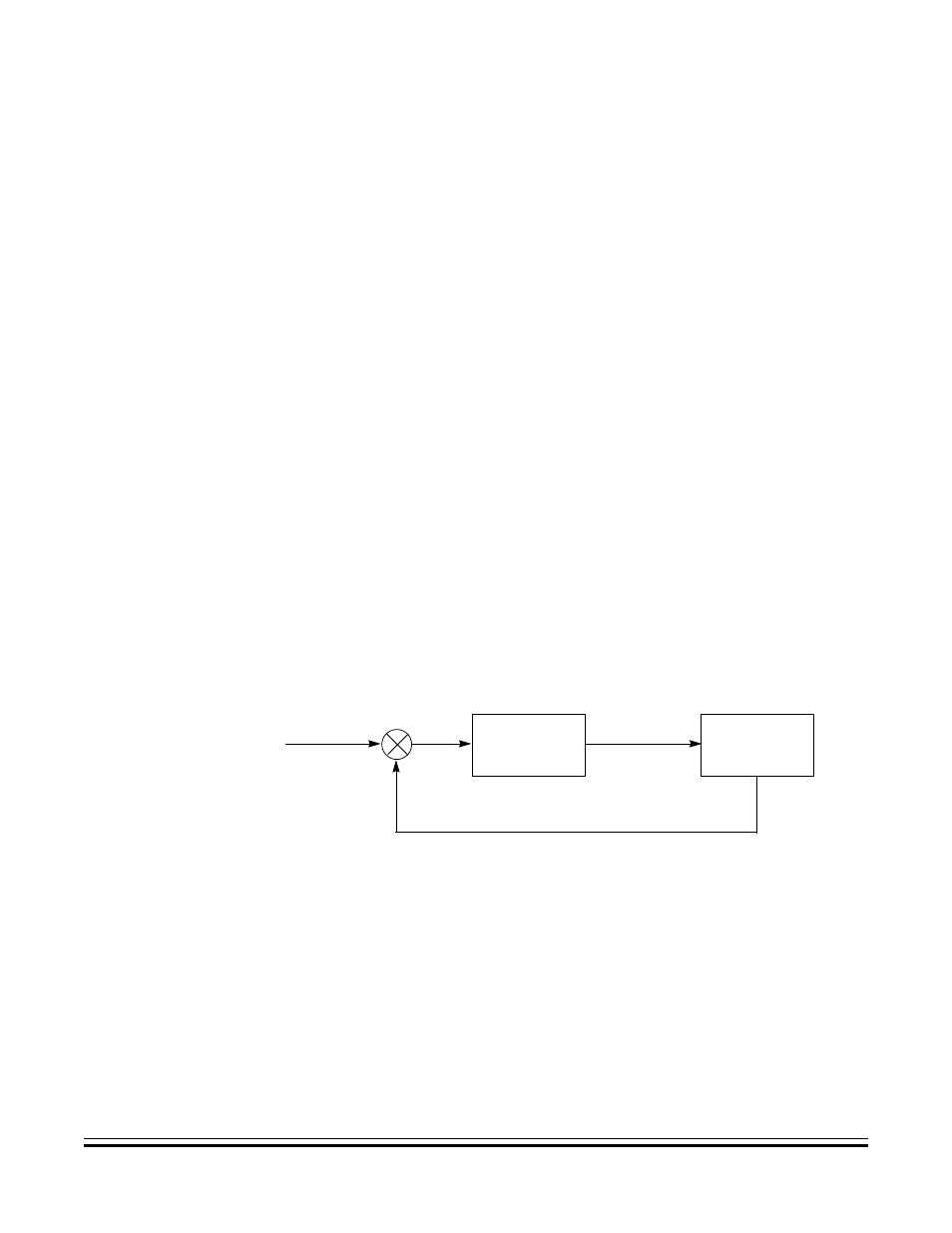

5.3.7 Process Desired Speed Setting

The desired speed, held in register Speed_Desired, is calculated from

the following formula:

Speed_Desired = Sp_Input*Coef_Speed_Inp/255 +

Speed_Min_U8

5.3.8 Processs Speed Control

The general principle of the speed PI control loop is illustrated in

.

Figure 5-3. Closed Loop Control System

The speed closed loop control is characterized by the feedback of the

actual motor speed.

The actual motor speed is calculated from zero crossing period:

Actual motor speed = 256*Per_Speed_MAX_Range/Per_ZCrosFlt_T2

(OutReg_U8)

(256*Per_Speed_MAX_Range/Per_ZCrosFlt_T2)

-

REFERENCE

SPEED

(Speed_Desired)

SPEED

ERROR

PI

CONTROLLER

PWM

DUTY CYCLE

CONTROLLED

SYSTEM

ACTUAL MOTOR

SPEED

F

re

e

sc

a

le

S

e

m

ic

o

n

d

u

c

to

r,

I

Freescale Semiconductor, Inc.

For More Information On This Product,

Go to: www.freescale.com

n

c

.

..