Caution, Warning – Goodman Mfg GKS9 User Manual

Page 24

24

T

O

PREVENT

UNRELIABLE

OPERATION

OR

EQUIPMENT

DAMAGE

,

THE

GAS

MANIFOLD

PRESSURE

MUST

BE

AS

SPECIFIED

ON

THE

UNIT

RATING

PLATE

. O

NLY

MINOR

ADJUSTMENTS

SHOULD

BE

MADE

BY

ADJUSTING

THE

GAS

VALVE

PRESSURE

REGULATOR

.

CAUTION

Inlet gas supply pressures must be maintained within the ranges

specified below. The supply pressure must be constant and avail-

able with all other household gas fired appliances operating. The

minimum gas supply pressure must be maintained to prevent

unreliable ignition. The maximum must not be exceeded to pre-

vent unit overfiring.

Propane Gas

Natural Gas

Inlet Gas Supply Pressure

Minimum:5.0" W.C. Maximum :10.0" W.C.

Minimum:11.0" W.C. Maximum :13.0" W.C.

H

IGH

A

LTITUDE

D

ERATE

When this furnace is installed at high altitude, the appropriate High

Altitude orifice kit must be applied. This is required due to the

natural reduction in the density of both the gas fuel and combus-

tion air as altitude increases. The kit will provide the proper design

certified input rate within the specified altitude range.

High altitude kits are purchased according to the installation alti-

tude and usage of either natural or propane gas. Contact your

distributor for a tabular listing of appropriate altitude ranges and

corresponding manufacturer’s high altitude (Natural, Propane Gas,

and/or Pressure Switch) kits.

Do not derate the furnace by adjusting the manifold pressure to a

lower pressure than specified on the furnace rating plate. The

combination of the lower air density and a lower manifold pressure

will prohibit the burner orifice from drawing the proper amount of

air into the burner. This may cause incomplete combustion, flash-

back, and possible yellow tipping.

In some areas the gas supplier may artificially derate the gas in an

effort to compensate for the effects of altitude. If the gas is artifi-

cially derated, the appropriate orifice size must be determined

based upon the BTU/ft

3

content of the derated gas and the altitude.

Refer to the National Fuel Gas Code, ANSI Z223.1, and information

provided by the gas supplier to determine the proper orifice size.

A different pressure switch may be required at high altitude regard-

less of the BTU/ft

3

content of the fuel used. Contact your distributor

for a tabular listing of appropriate altitude ranges and correspond-

ing manufacturer’s pressure switch kits.

P

ROPANE

G

AS

C

ONVERSION

P

OSSIBLE

PROPERTY

DAMAGE

,

PERSONAL

INJURY

OR

DEATH

MAY

OCCUR

IF

THE

CORRECT

CONVERSION

KITS

ARE

NOT

INSTALLED

. T

HE

APPROPRIATE

KITS

MUST

BE

APPLIED

TO

ENSURE

SAFE

AND

PROPER

FURNACE

OPERATION

. A

LL

CONVERSIONS

MUST

BE

PERFORMED

BY

A

QUALIFIED

INSTALLER

OR

SERVICE

AGENCY

.

WARNING

This unit is configured for natural gas. The appropriate

manufacturer’s propane gas conversion kit, must be applied for

propane gas installations. Refer to the Section VIII, Propane Gas

/ High Altitude Installations section for details.

G

AS

V

ALVE

This unit is equipped with a 24 volt gas valve controlled during

furnace operation by the integrated control module. As shipped,

the valve is configured for natural gas. The valve is field convertible

for use with propane gas by replacing the regulator spring with a

propane gas spring from an appropriate manufacturer’s propane

gas conversion kit. Taps for measuring the gas supply pressure

and manifold pressure are provided on the valve.

The gas valve has a manual ON/OFF control located on the valve

itself. This control may be set only to the “ON” or “OFF” position.

Refer to the lighting instructions label or Section XIV, Startup Pro-

cedure & Adjustment for use of this control during start up and shut

down periods.

G

AS

P

IPING

C

ONNECTIONS

G

ENERAL

T

O

AVOID

POSSIBLE

UNSATISFACTORY

OPERATION

OR

EQUIPMENT

DAMAGE

DUE

TO

UNDERFIRING

OR

EQUIPMENT

,

USE

THE

PROPER

SIZE

OF

NATURAL

/

PROPANE

GAS

PIPING

NEEDED

WHEN

RUNNING

PIPE

FROM

THE

METER

/

TANK

TO

THE

FURNACE

.

CAUTION

When sizing a trunk line, be sure to include all appliances which

will operate simultaneously when sizing a trunk line.

The gas piping supplying the furnace must be properly sized based

on the gas flow required, specific gravity of the gas, and length of

the run. The gas line installation must comply with local codes, or

in their absence, with the latest edition of the National Fuel Gas

Code, ANSI Z223.1.

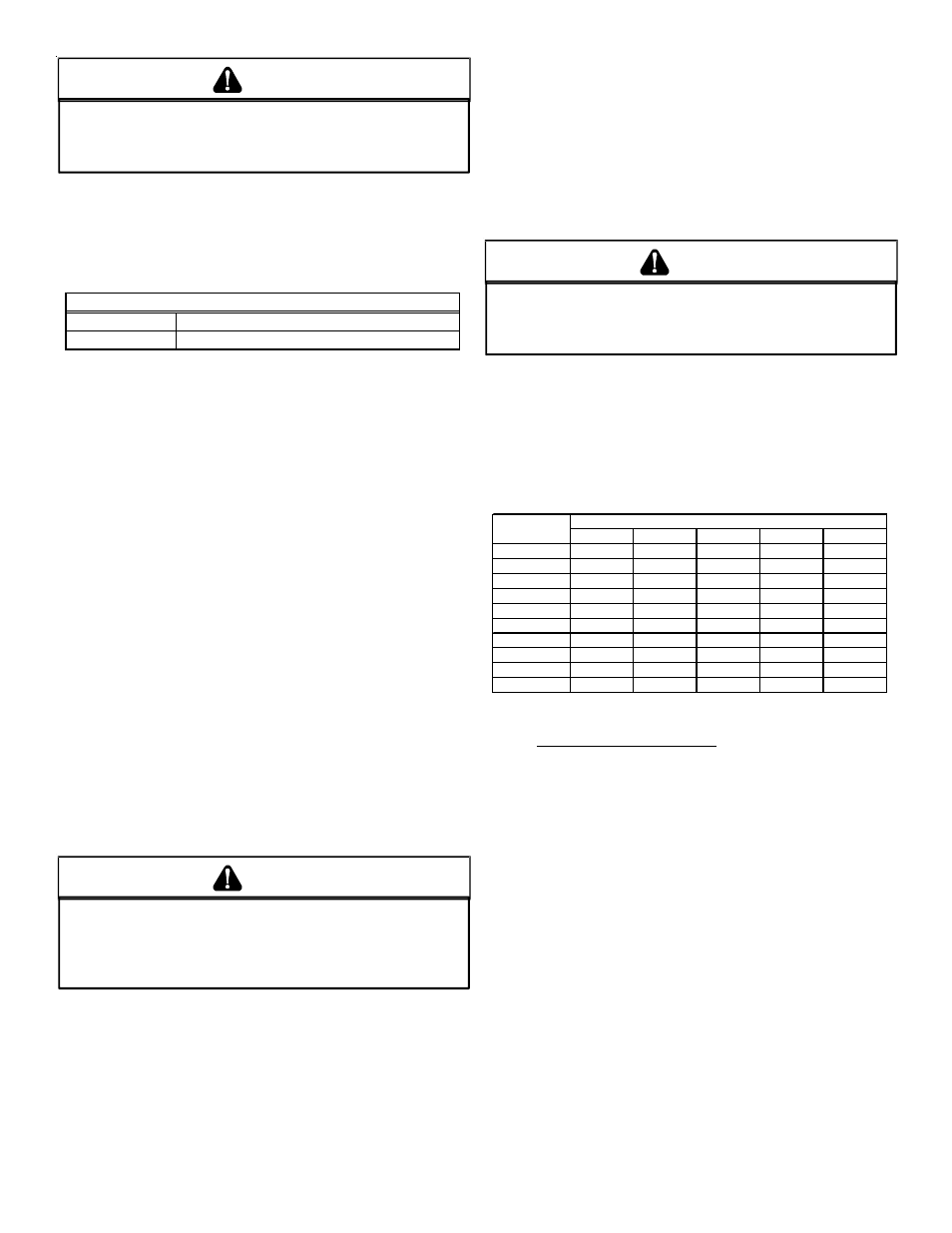

Natural Gas Capacity of Pipe

In Cubic Feet of Gas Per Hour (CFH)

Length of

Nominal Black Pipe Size

Pipe in Feet

1/2"

3/4"

1"

1 1/4"

1 1/2"

10

132

278

520

1050

1600

20

92

190

350

730

1100

30

73

152

285

590

980

40

63

130

245

500

760

50

56

115

215

440

670

60

50

105

195

400

610

70

46

96

180

370

560

80

43

90

170

350

530

90

40

84

160

320

490

100

38

79

150

305

460

(Pressure 0.5 psig or less and pressure drop of 0.3" W.C.; Based on

0.60 Specific Gravity Gas)

CFH =

BTUH Furnace Input

Heating Value of Gas (BTU/Cubic Foot)

To connect the furnace to the building’s gas piping, the installer

must supply a ground joint union, drip leg, manual shutoff valve,

and line and fittings to connect to gas valve. In some cases, the

installer may also need to supply a transition piece from 1/2" pipe

to a larger pipe size.

The following stipulations apply when connecting gas piping. Re-

fer to Gas Piping Connections figure for typical gas line connec-

tions to the furnace.

•

Use black iron or steel pipe and fittings for building piping.

Where possible, use new pipe that is properly chamfered,

reamed, and free of burrs and chips. If old pipe is used, be

sure it is clean and free of rust, scale, burrs, chips, and old

pipe joint compound.

•

Use pipe joint compound on male threads ONLY. Always

use pipe joint compound (pipe dope) that is APPROVED

FOR ALL GASSES. DO NOT apply compound to the first two

threads.

•

Use ground joint unions.

•

Install a drip leg to trap dirt and moisture before it can enter

the gas valve. The drip leg must be a minimum of three

inches long.