Please read the following carefully, Troubleshooting – Harbor Freight Tools 98233 User Manual

Page 16

SKU 98233

For technical questions, please call 1-800-444-3353.

Page 16

pleaSe read The FOllOwInG careFullY

THE MANUFACTURER AND/OR DISTRIBUTOR HAS PROVIDED THE PARTS LIST AND ASSEMBLY

DIAGRAM IN THIS MANUAL AS A REFERENCE TOOL ONLY. NEITHER THE MANUFACTURER OR

DISTRIBUTOR MAKES ANY REPRESENTATION OR WARRANTY OF ANY KIND TO THE BUYER THAT

HE OR SHE IS qUALIFIED TO MAKE ANY REPAIRS TO THE PRODUCT, OR THAT HE OR SHE IS

qUALIFIED TO REPLACE ANY PARTS OF THE PRODUCT. IN FACT, THE MANUFACTURER AND/

OR DISTRIBUTOR ExPRESSLY STATES THAT ALL REPAIRS AND PARTS REPLACEMENTS SHOULD

BE UNDERTAKEN BY CERTIFIED AND LICENSED TECHNICIANS, AND NOT BY THE BUYER. THE

BUYER ASSUMES ALL RISK AND LIABILITY ARISING OUT OF HIS OR HER REPAIRS TO THE

ORIGINAL PRODUCT OR REPLACEMENT PARTS THERETO, OR ARISING OUT OF HIS OR HER

INSTALLATION OF REPLACEMENT PARTS THERETO.

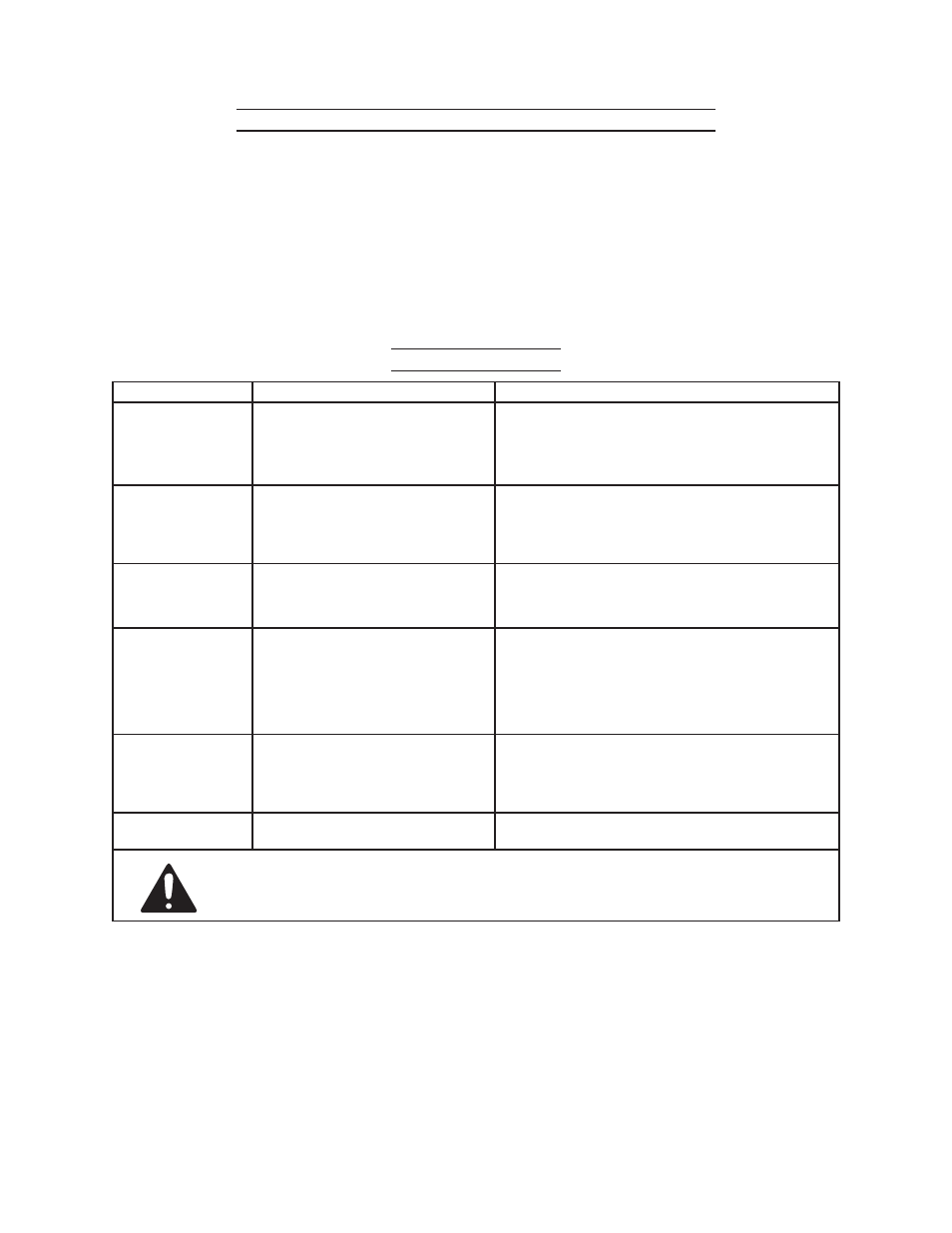

Troubleshooting

problem

possible causes

likely Solutions

Tool will not start

No power at outlet.

1.

Cord not connected.

2.

Line voltage incorrect.

3.

Check power at outlet.

1.

Check that cord is plugged in.

2.

Make sure the welder is plugged into a 230V

3.

electrical outlet.

No weld output

with ready light on

Weld cable loose.

1.

Bad work clamp to workpiece

2.

connection.

Tighten weld cable connection at welder.

1.

Make sure the area where the clamp is

2.

attached is clean, exposed metal; free of dirt,

paint and oil.

No weld output;

high temperature

light on

Welder overheated.

1.

Duty cycle or amps too high.

2.

Airflow is blocked.

3.

Allow unit to cool with the fan on.

1.

Reduce duty cycle or amps.

2.

Clean vents and fan out with compressed air.

3.

Erratic or improper

arc or welding

output

Bad weld connections.

1.

Polarity incorrect.

2.

Workpiece painted or dirty.

3.

Ceramic Nozzle obstructed by

4.

welding spatter.

Clean and tighten weld connections.

1.

Connect polarity correctly.

2.

Clean workpiece thoroughly.

3.

Clean or replace nozzle.

4.

Fan not operating

Fan blocked/dirty.

1.

Fan broken.

2.

Remove obstruction and clean with

1.

compressed air.

Have the fan replaced by a qualified service

2.

technician.

Main Supply Fuse

shuts off frequently

Circuit Breaker rating is too low.

Install a circuit breaker rated for greater than 20

Amps.

Follow all safety precautions whenever diagnosing or servicing the

tool. disconnect power supply before service.