Harbor Freight Tools 94164 User Manual

Page 19

For technical questions, please call 1-800-444-3353;

troubleshooting section at end of manual.

Page 19

SKU 94164

job at hand. The distance (if any) between the two workpieces must be controlled

properly to allow the weld to hold both sides securely while allowing the weld to

penetrate fully into the joint.

Set the desired welding current (30 to 140 amps) for the type of metal being welded,

7.

using the Wire Speed Control Knob (17) and Voltage Controls (18, 19).

(See Figure L.)

Make sure the Power Switch is in its

8.

“OFF” position. Then plug Power Cord of

the Welder into a dedicated, 220 VAC, 25 amp line with delayed action type circuit

breaker or fuse.

While holding the Welding Torch (15), with the Welding Wire clearly out of the way

9.

of any grounded objects, turn the Power Switch to its

“On” position.

Momentarily squeeze the Trigger (15d) of the Welding Torch (15) to test the wire

10.

feed speed. If necessary, adjust the speed by turning the Wire Speed Control Knob

(17).

(See Figure L.)

Orient yourself on the area to be welded, then place a Face Shield over your

11.

eyes.

12.

WARnInG! never look at the ignited arc without AnSI-approved,

arc-shaded, eye protection in a full face shield. permanent eye

damage or blindness can occur. Skin burns can occur. never

breathe arc fumes. (See page 8.)

hOLDInG thE WELDInG tORCh

Hold the Welding Torch (15) in one hand and the face shield in the other. If a hands-

13.

free welding shield is used, then both hands can be used to control the Welding

Torch.

The Welding Wire should be directed straight into the joint.

14.

This gives an angle of 90 degrees (straight up and down) for

groove (end to end) welds, and an angle of 45 degrees for

fillet (T-shaped) welds.

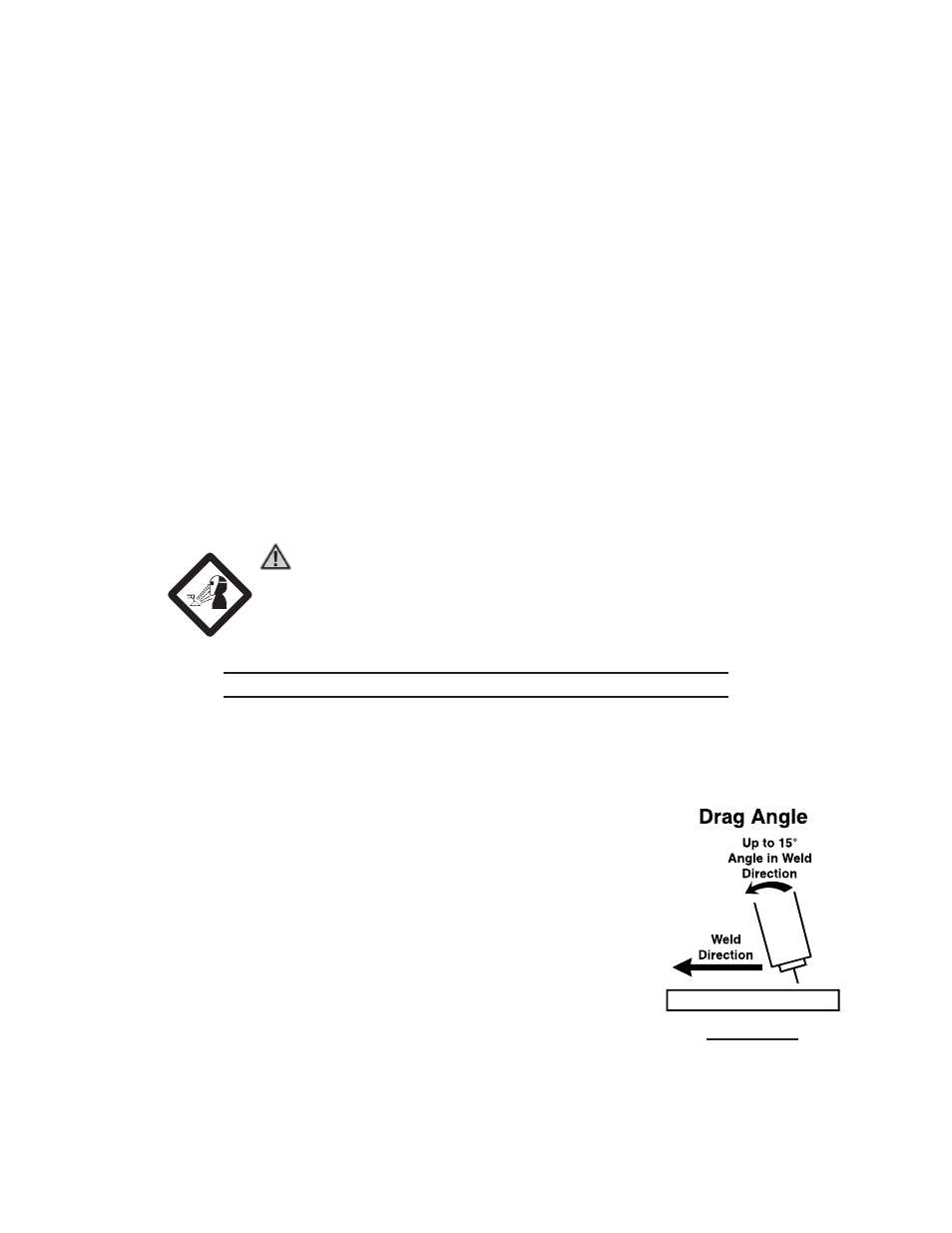

The end of the Welding Torch should be tilted so that the

15.

Welding Wire is angled anywhere in between straight on and

15 degrees in the direction of the weld. The amount of tilt is

called the

“drag angle”. (See Figure M.)

The Welding Wire should extend no more than 1/2” past the

16.

Nozzle (15h) of the Welding Torch (15). This distance is

called “stickout”.

(See Figure M.)

Set the Wire Speed and Voltage Controls (17, 18, 19) to the recommended start

17.

settings as shown in the Weld Settings Chart on the next page.

(See Figure n.)

FIGURE M