Warning – Harbor Freight Tools 94164 User Manual

Page 13

For technical questions, please call 1-800-444-3353;

troubleshooting section at end of manual.

Page 13

SKU 94164

WARnInG!

ExERCISE ExtREME CAUtIOn - RISK OF FIRE AnD/OR ELECtRIC ShOCK!

the following steps require applying power to the Welder. Do not touch

anything with the torch handle or Welding Wire or an arc will be ignited.

Do not touch the internal components of the unit while it is plugged in.

Plug the Power Cord (13) into its 220 volt, grounded, electrical outlet. Then, turn

8.

the Welder ON.

Point the Torch Handle away from all objects. Then, squeeze the Trigger Switch

9.

(15d) on the Torch Handle until the Welding Wire feeds through the Head Tube

(15f) of the Torch Handle about 2 inches. If necessary, move the Torch Handle

slightly in a circular motion to help feed the Welding Wire properly out of the Head

Tube. (See Figure F.)

NOTE: If the Welding Wire does not feed properly, and the Spool is stationary,

10.

turn the Welder off. Unplug the Welder. Slightly tighten the Tension Adjusting

Knob (10b) on the Wire Feed Assembly, and rewind the Welding Wire slightly

before retrying. (See Figure E.)

To check the tension on the Wire Feed Assembly, feed the Welding Wire against

11.

a piece of scrap wood from 2 to 3 inches away. If the Wire stops instead of

bending, turn the Welder OFF. Unplug the unit from its electrical outlet. Then,

slightly tighten the Tension Adjusting Knob (10b) on the Wire Feed Assembly. Do

not over-tighten; this can stop the wheel completely and harm the drive motor.

(See Figure E.)

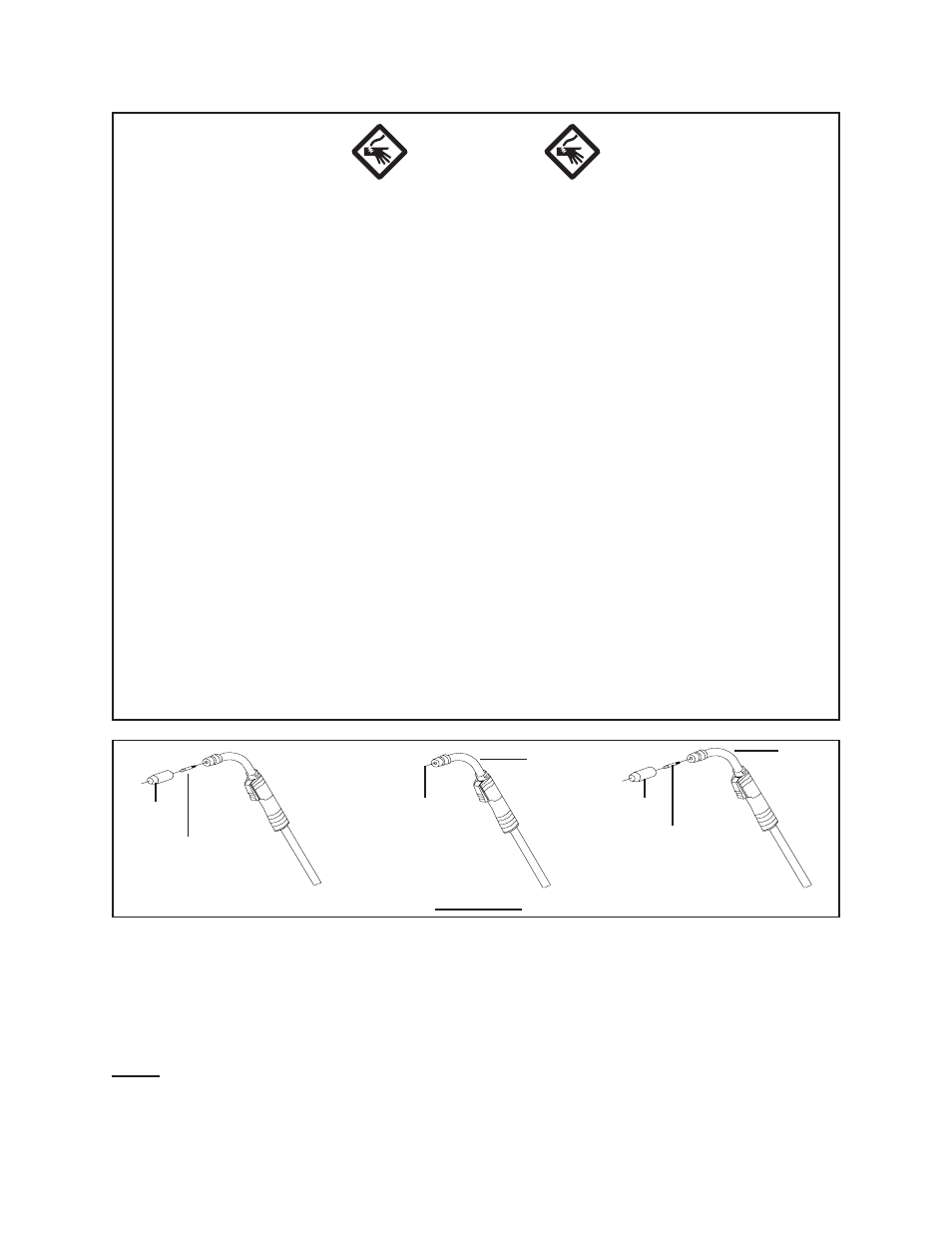

FIGURE F

COntACt

tIp

(15g)

nOZZLE

(15h)

WELDInG

WIRE

hEAD

tUBE

(15f)

nOZZLE

(15h)

COntACt

tIp

(15g)

hEAD

tUBE

(15f)

12. Turn the Welder OFF, unplug it, and discharge the electrode to ground. Insert the

Contact Tip (15g) onto the Welding Wire and screw it firmly into the Head Tube (15f)

of the Torch Handle. Replace the Nozzle (15h), and cut off any excess Welding

Wire over 1/2 inch. Then, close the Access Panel (12) of the Welder.

(See Figure F.)

note: When installing wire of a different size or composition, you will also need to change

wire settings, set the gun polarity, and, possibly, install a gas cylinder. See pages

14-16.

REV 08j