7. selecting weld cable sizes, 8. remote 14 receptacle rc5 information – Hobart Welding Products CONTRACTOR 3025 User Manual

Page 20

OM-492 Page 16

4-7.

Selecting Weld Cable Sizes

Total Cable (Copper) Length In Weld Circuit Not Exceeding

Welding

Amperes

100 ft (30 m) Or Less

150 ft

(45 m)

200 ft

(60 m)

250 ft

(70 m)

300 ft

(90 m)

350 ft

(105 m)

400 ft

(120 m)

10 – 60%

Duty Cycle

60 – 100% Duty

Cycle

10 – 100% Duty Cycle

100

4

4

4

3

2

1

1/0

1/0

150

3

3

2

1

1/0

2/0

3/0

3/0

200

3

2

1

1/0

2/0

3/0

4/0

4/0

250

2

1

1/0

2/0

3/0

4/0

2-2/0

2-2/0

300

1

1/0

2/0

3/0

4/0

2-2/0

2-3/0

2-3/0

350

1/0

2/0

3/0

4/0

2-2/0

2-3/0

2-3/0

2-4/0

*Weld cable size (AWG) is based on either a 4 volts or less drop or a current density of at least 300 circular mils per ampere. Contact your

distributor for the mm

2

equivalent weld cable sizes.

S-0007-E

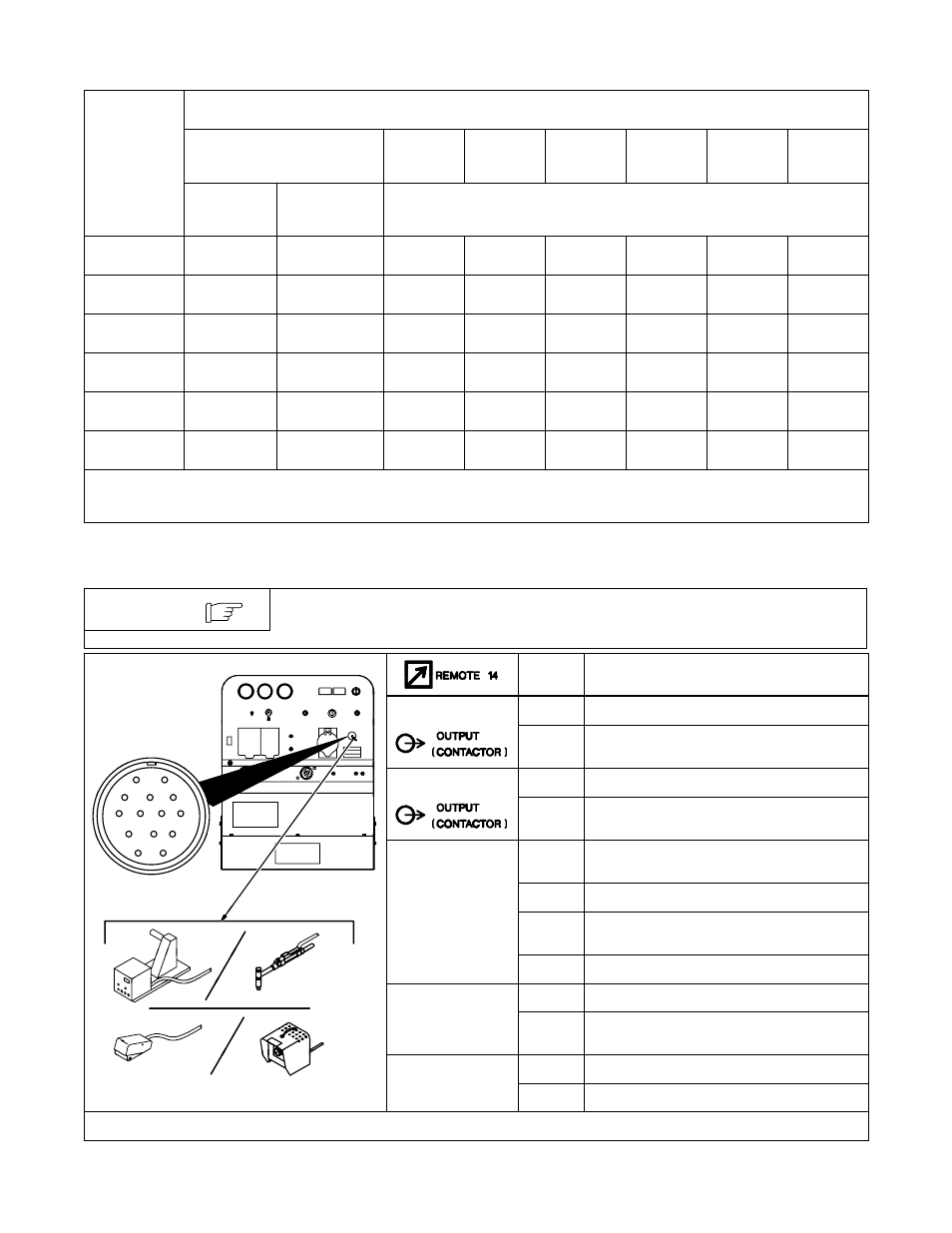

4-8.

Remote 14 Receptacle RC5 Information

Engine runs at weld/power speed whenever a device connected to the remote 14

receptacle is running.

NOTE

Socket*

Socket Information

24 VOLTS AC

A

24 volts ac. Protected by circuit breaker CB11.

24 VOLTS AC

B

Contact closure to A completes 24 volts ac

contactor control circuit.

A

J

K

115 VOLTS AC

I

115 volts ac. Protected by circuit breaker CB12.

B

K

I

C

L

N

H

115 VOLTS AC

J

Contact closure to I completes 115 volts ac

contactor control circuit.

D

M

G

E

F

C

Output to remote control; 0 to +10 volts dc, +10

volts dc in MIG mode.

REMOTE

D

Remote control circuit common.

OUTPUT

CONTROL

E

0 to +10 volts dc input command signal from

remote control.

M

CC/CV select (CC/CV models).

A/V

F

Current feedback; +1 volt dc per 100 amperes.

A/V

AMPERAGE

VOLTAGE

H

Voltage feedback; +1 volt dc per 10 output recep-

tacle volts.

G

Circuit common for 24 and 115 volts ac circuits.

802 174-E

GND

K

Chassis common.

*The remaining sockets are not used.