5. fuel consumption, 1. installing welding generator – Hobart Welding Products CONTRACTOR 3025 User Manual

Page 16

OM-492 Page 12

193 458

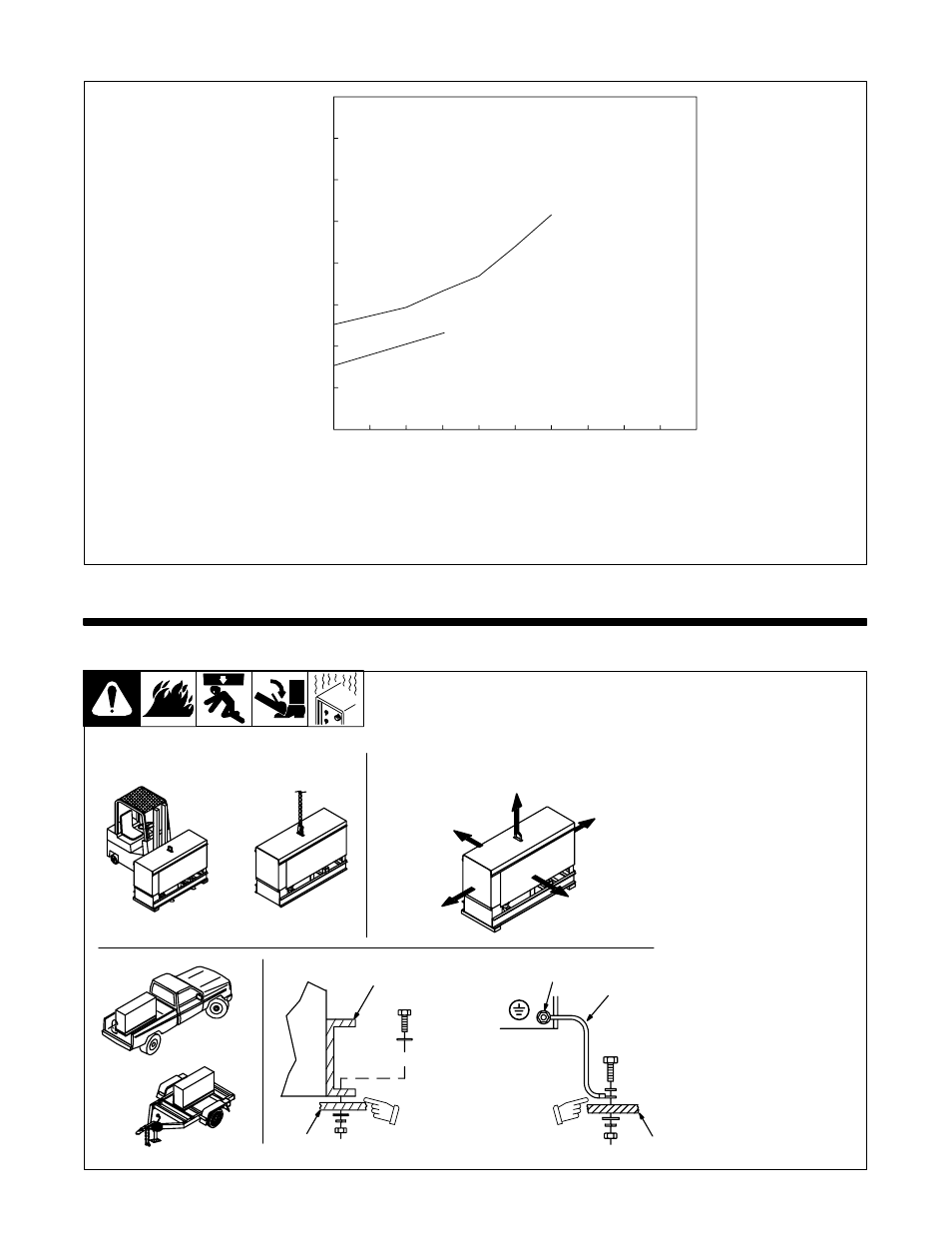

3-5.

Fuel Consumption

0

50

100 150 200 250 300 350 400 450 500

DC WELD AMPERES AT 100% DUTY CYCLE

3600 RPM

0

0.25

0.50

0.75

1.00

1.25

1.50

1.75

2.00

0.40

0.21

0.62

0.83

1.25

1.04

1.46

1.70

1.98

0.95

2.84

3.78

5.67

4.73

6.62

7.57

U.S. GAL./HR.

IM

P

. GAL./HR.

LITERS/HR.

IDLE

SECTION 4 – INSTALLATION

install1 12/99 – Ref. 800 652 / Ref. 800 477-A / 158 936-A / S-0854

Y

Do not weld on base. Weld-

ing on base can cause fuel

tank fire or explosion. Bolt

unit down using holes pro-

vided in base.

Y

Always ground generator

frame to vehicle frame to pre-

vent electric shock and static

electricity hazards.

1

Generator Base

2

Metal Vehicle Frame

3

Equipment Grounding

Terminal

4

Grounding Cable

Use #10 AWG or larger insulated

copper wire.

Y

If unit does not have GFCI re-

ceptacles, use GFCI-

protected extension cord.

1

2

Electrically bond genera-

tor frame to vehicle frame

by metal-to-metal contact.

GND/PE

3

4

2

OR

OR

18 in

(460 mm)

18 in

(460 mm)

18 in

(460 mm)

18 in

(460 mm)

18 in

(460 mm)

OR

Movement

Airflow Clearance

Location

Grounding

Y

Do not lift unit from end.

4-1.

Installing Welding Generator