Inspection, maintenance, and cleaning, Troubleshooting – Harbor Freight Tools CENTRALPNEUMATIC 97526 User Manual

Page 7

Page 7

SKU 97526

For technical questions, please call 1-800-444-3353.

INSPECTION, MAINTENANCE, AND CLEANING

1.

WARNING! Make sure air compressor is unplugged and that the Nailer is

disconnected from its Air Supply before performing any inspection, maintenance,

or cleaning procedures.

2.

BEFORE EACH USE, inspect the general condition of this tool. Check for

loose screws, misalignment or binding of moving parts, cracked or broken parts,

damaged air hoses, and any other condition that may affect its safe operation. If

abnormal noise or vibration occurs, have the problem corrected before further use.

Do not use damaged equipment.

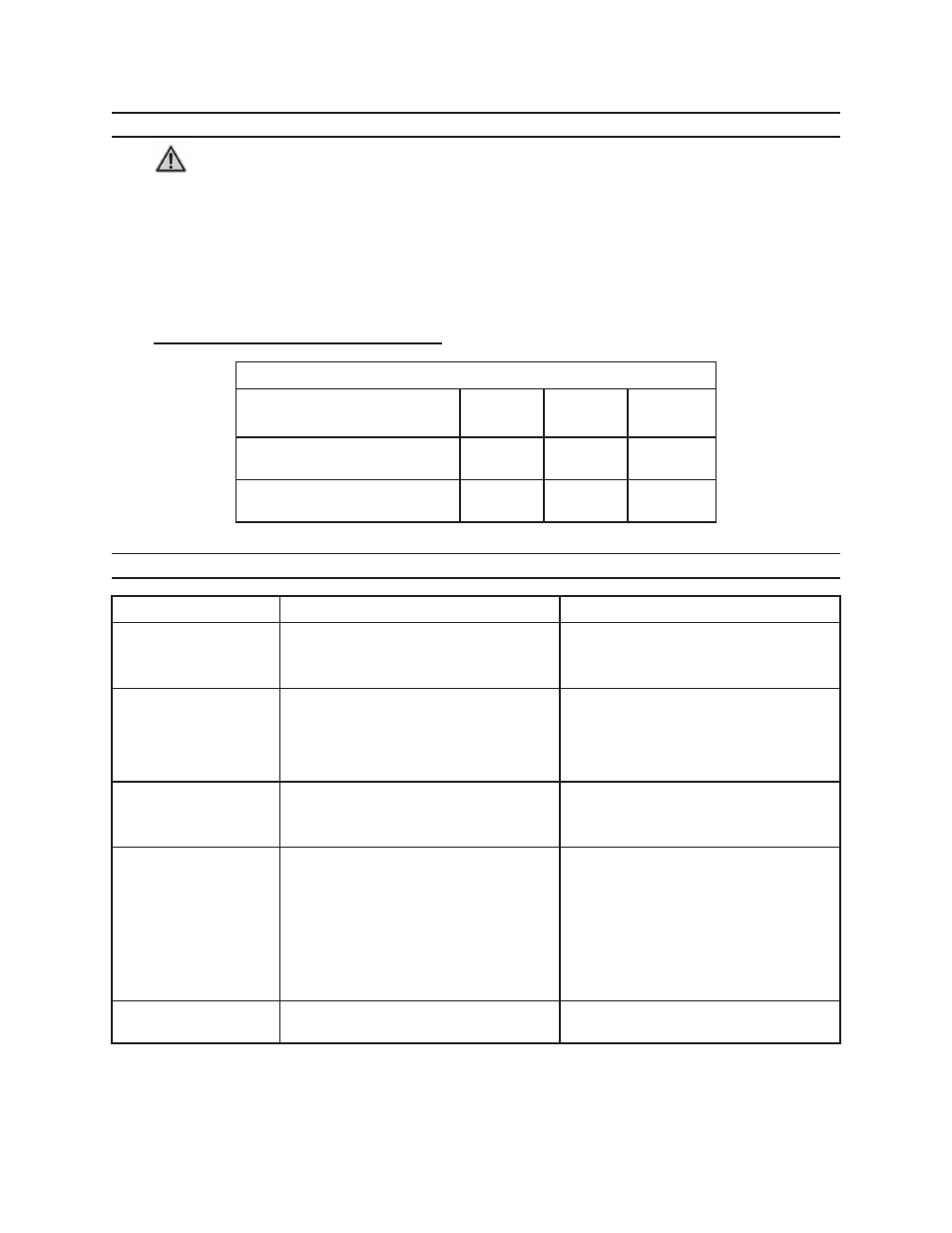

MAINTENANCE CHART

Maintenance Type

Before

Use

After

Use

Monthly

Inspect the Nailer for damage

(see #2, above)

X

X

Wipe off with clean, moist

cloth

X

X

TROUBLESHOOTING

Problem

Possible Causes

Probable Solutions

Air leak near top of

tool or in trigger area.

1. Loose screws.

2. Worn or damaged o-rings or seals.

1. Tighten screws.

2. See qualified service technician for

repairs.

Nailer does not

operate or operates

sluggishly

1. Inadequate air supply.

2. Inadequate lubrication.

3. Worn or damaged o-rings or seals.

1. Check screws.

2. See qualified service technician for

repairs.

Air leak near bottom

of Nailer

1. Loose screws.

2. Worn or damaged o-rings or

bumper.

1. Tighten screws.

2. See qualified service technician for

repairs.

Nailer jam frequently

1. Incorrect fasteners.

2. Damaged fasteners.

3. Magazine or Nozzle screw loose.

4. Magazine is dirty.

5. Driver is worn or damaged.

1. Check fasteners for correct size.

2. Replace with undamaged

fasteners.

3. Tighten screws.

4. Clean screws.

5. See qualified service technician for

repairs.

Other

See qualified service technician for

repairs.