General operating instructions – Harbor Freight Tools 45861 User Manual

Page 16

Page 16

SKU 45861

For technical questions, please call 1-800-444-3353.

40

80

40

120

a

80

b

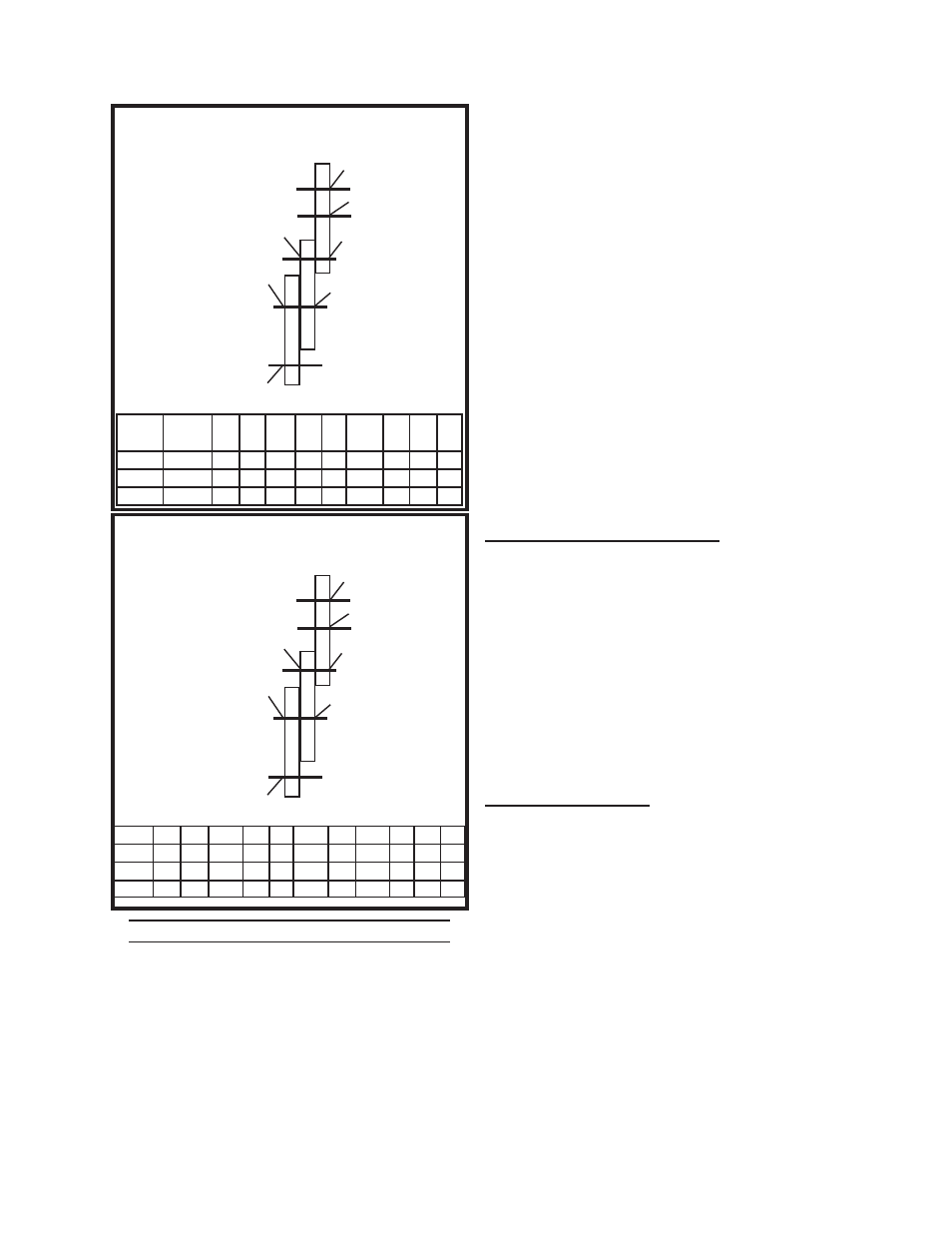

threading rate portion of machine plate

for inches

Lever

a

Lever

b

1 2 3

4 5 6

7 8 9

60

30

8 9 9.5 10 11 11.5 12 13 14

30

30

16 18 19 20 22 23 24 26 28

30

60

32 36 38 40 44 46 48 52 56

40

80

40

127

a

120

b

threading rate portion of machine plate

for Millimeters

Lever

7 1 1

4 7 1

1 1

7 1 1

a

30 28 30 30 30 30 30 42 60 60 60

b

60 60 60 45 30 36 30 36 30 36 30

0.5 0.7 0.75 0.8 1 1.25 1.5 1.75 2 2.5 3

general Operating instructions

Every ten hours of operation, lubri-

cate the lathe’s gears and ways with white

lithium grease, as directed in the Mainte-

nance Section of this manual.

The Lathe can perform a wide variety

1.

of operations; the purchase of refer-

ence materials, such as books about

machining or engineering tables, is

highly recommended.

If Lathe use requires a higher de-

2.

gree of accuracy than supplied by

the standard set-up, have the Lathe

serviced by a qualified machinist.

Settings for the spindle, chuck, gibs,

3.

ways, and ends, will be determined

by the length of the stock and the

intended operation.

Turn the chuck by hand to make sure

4.

it rotates smoothly.

Plug the Lathe into a standard,

5.

grounded 120V electrical outlet.

general Milling guidelines

When performing any operation with

1.

the Lathe it is best to proceed slowly

and make several passes.

A 1000th of an inch of movement

2.

yields a 2000th inch cut.

Use of a high-quality cutting fluid (not

3.

included) will greatly aid in most mill-

ing processes.

Facing Operations

Facing is the process of removing

metal from the end of a workpiece to pro-

duce a flat surface.

To safely perform a facing operation

1.

the jaws of the chuck must be as

close as possible to the end of the

workpiece. The workpiece should

not extend more than 2 or 3 times its

diameter from the chuck jaws unless

the steady rest is used to support the

end of the workpiece.