Maintenance – HONDA MM60 User Manual

Page 51

MAINTENANCE

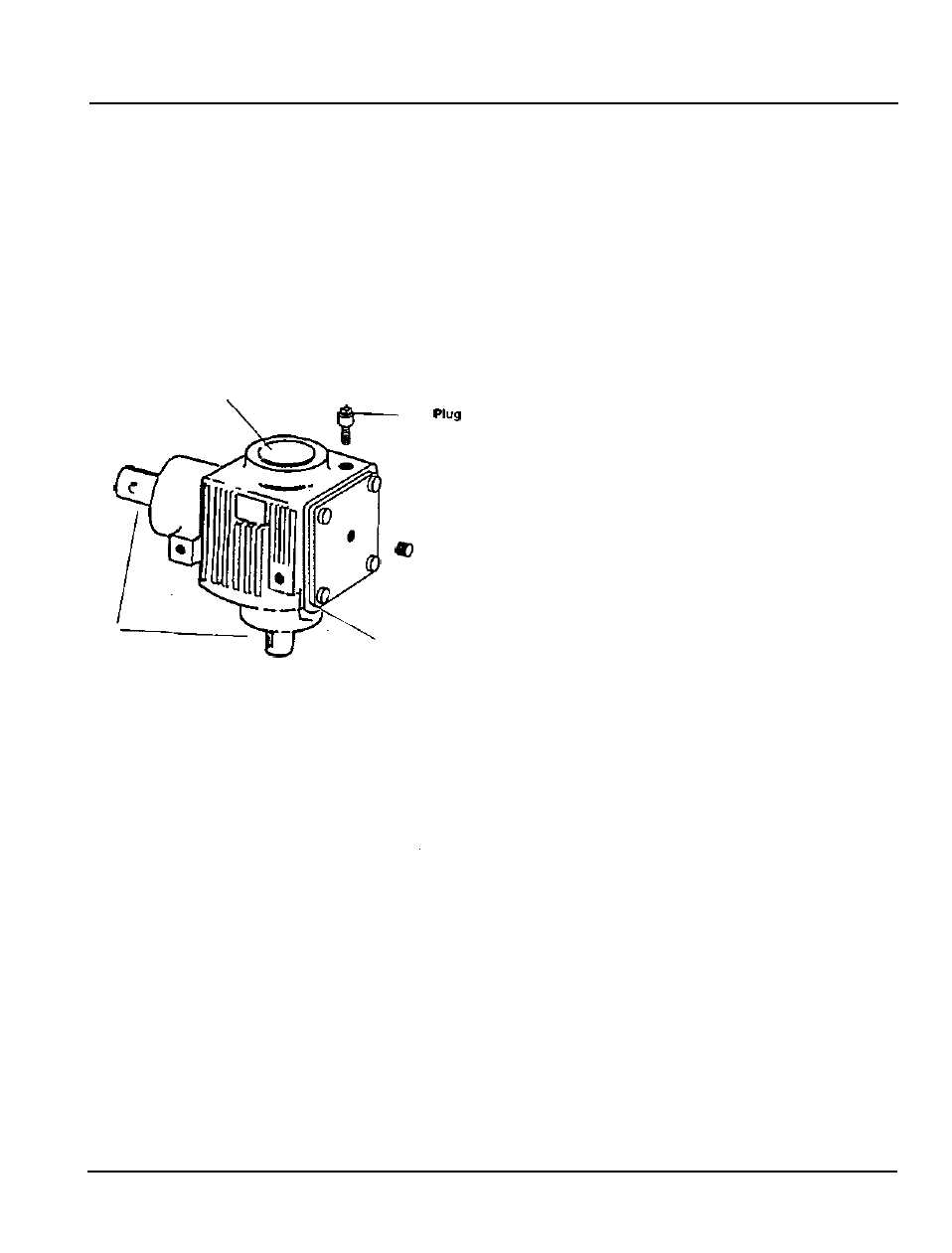

Seal

Seal

Vent

Gearbox

gasket

Gear Box

Leakage Repair

1. Bore-tite

™, a sealant, is used on the outer

diameter of the seals. Substitute seals may not

meet original equipment specifications and

could cause leakage.

2.

Clean gearbox exterior to remove all foreign

material. When opening, use care to prevent

foreign material from entering gearbox.

3.

To repair horizontal seal, vertical

shaft, or

leakage between cover and gearbox, remove

vent plug

and drain gear lube from box. Re-

move leaking seal and replace (refer to Seal

Installation). Use

care to prevent rolling seal lip

under. Replace gasket between cover and.

gearbox.

Seal Installation

Proper seal installation is important. An improperly

installed seal

will

leak and could result in bearing

failure.

1. Clean areas in housing where seal outer diam-

eter seats. Inspect gear shafts. Pay specific

attention to areas where seals seat. Check for

cracks, grooves, nicks or bumps. Replace

housing

or

shaft if damage cannot be repaired

by resurfacing with emery cloth.

2. Lubricate seal lip and carefully guide over shaft

using a blunt tool such as a letter opener. Be

careful not to

roll

seal lip under. Do not use a

knife as

it will nick and ruin seal.

3.

Place seal squarely on housing (spring-loaded

lip toward inside of gearbox). Select a seal

driver, a piece of pipe

or

tubing with an OD that

will set on outside edge of seal but will clear

housing.

A driver that is too small will bow seal

cage and ruin seal.

4.

Carefully press seal into housing, preventing

distortion to metal seal cage. Seat vertical seal

flush with housing and horizontal seal against

shoulder in housing.

5. Distortion to seal case or damage to seal lip

will

cause seal to leak. Remove and replace seals

damaged in installation.

6.

Check for proper vent plug operation and

fill

gearbox with

8 oz. of SAE 90W gear lube.

50