Maintenance – HONDA MM60 User Manual

Page 46

MAINTENANCE

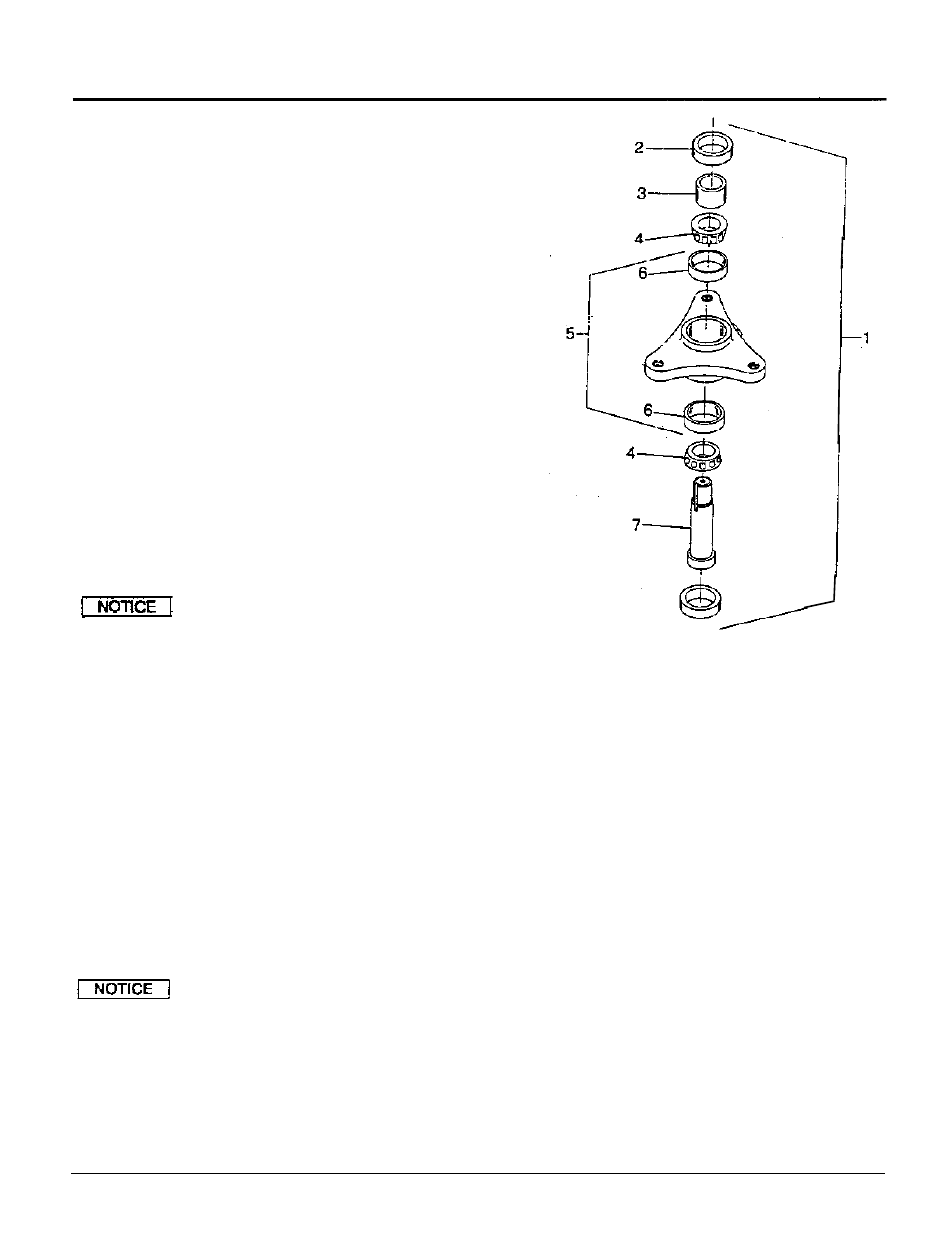

Blade Spindle Assembly

1. Bearing cups and cones are designed to work

together. It is important to position them so

bearing cone taper mates with bearing cup

taper.

2. Lubricate new cups with a light oil. Place them

in spindle housing so they will mate with cones.

Seat cups against machined shoulder of hous-

ing with a press or by placing a large drift on the

flat lip and driving them into housing.

3. Place bottom bearing cone onto spindle shaft

with taper up. Seat on bottom shoulder of shaft

with a press.

4. Insert shaft and bearing cone assembly through

bottom of housing.

Fill housing cavity with a

lithium grease of

#2 consistency with a

MOLY

(molybdenum disulfide) additive.

5. Place top bearing cone on shaft to mate with

top bearing cup.

Bearing adjustment is set by

pressing sleeve against bearing cone until

proper adjustment is attained.

6.

Install sleeve on shaft and press sleeve and

bearing cone onto shaft until all bearing free

play is removed and there is a slight drag

(similar to adjusting the front wheel bearings on

an automobile). Check by spinning spindle. It

should turn freely.

6. Be careful not to over-tighten bearings. Proper

bearing adjustment

is

essential to good bearing

life.

7.

Should you over-tighten bearings, hold spindle

housing and rap spindle shaft with a lead

hammer to loosen bearings. Readjust bearings

until proper setting is obtained.

Improper positioning of seals

can cause seal failure.

8.

Proper seal installation is important.

An improp-

erly installed seal will leak and could cause

bearing failure.

9.

Pull the rubber portion of seal back and locate.

spring.

1. S

pindle assembly

2. Seal

3.

Sleeve

4. Bearing cone

5. Housing and cups

6.

Cup

7.

Shaft

Spindle Assembly

45