Heat & Glo Fireplace RUTHERFORD 50 User Manual

Page 37

37

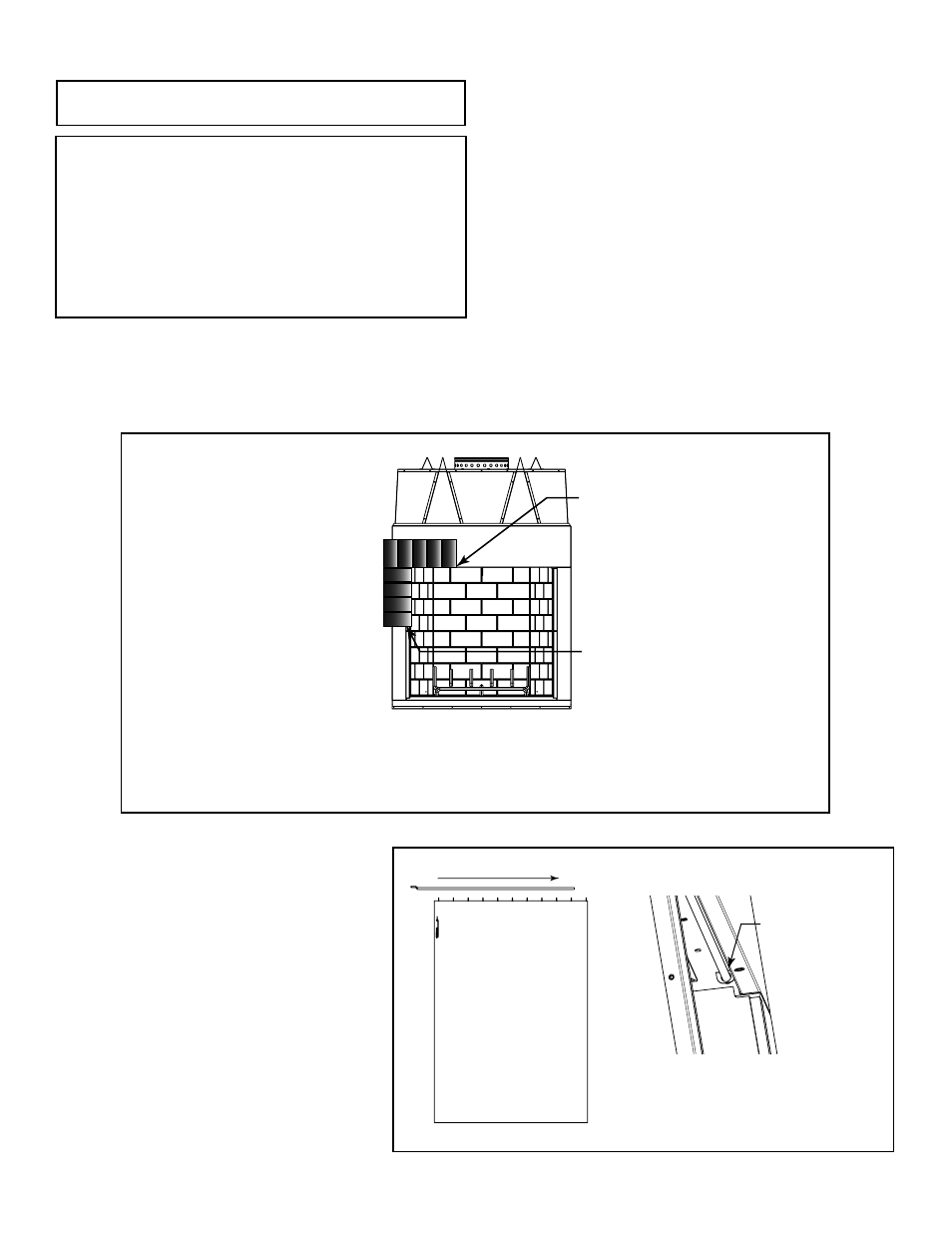

Center of Fireplace Opening

Round end of Rod through rings,

then into Screen Rod Clip

The noncombustible finishing

material across the

top of the fireplace opening will

be even with the lower edge of

the metal face.

Noncombustible finishing

materials MUST overlap

side faces by 1 1/4 in. (32 mm)

to cover the edges of the

refractory. Finished opening

should be 38 x 50 in. (965 x

1270 mm) to allow for door

installation.

Mortar should be applied

after the finishing material

is installed. Mortar will be

applied between the

finishing materials and the

refractory edges, bottom

and sides.

The seam between the

finishing materials and

firebox top must be sealed

with a high-temperature

silicone sealant.

The surface of the finished hearth extension and

the surface of the hearth refractory should be level.

F. Install Mortar

Tools Required:

Mortar bag

Drill

Trowel

3/32 drill bit (provided)

Mixing bucket

Phillips screwdriver

Sponge or spray bottle

Joint striker

Drill with mixing attachment (optional)

Bucket of water

Figure 11.3 Facing Materials and Mortar

G. Install Screens

• Remove one screen rod by removing

one screw (near the center of the top

front). Pull rod out of the hole. Keep

the screw.

• Lay one screen panel fl at and slide the

round end of the rod through the rings

starting at the handle side of screen.

Leave the last ring off the rod.

• Insert the rod through the hole in the

bracket. Slip the last ring over the rod

on the other side of the bracket.

• Fasten

the

fl at end of the screen rod

back in place using the screw removed

earlier.

• Repeat for the other screen panel.

• Mix approximately 1/3 of the mortar material with 1/2

gallon of water in the mixing bucket. Stir the mixture with

the mixing attachment and drill. The consistency should

allow the material to be squeezed from the mortar bag but

not too runny.

• Fill the mortar bag with the prepared mixture.

• Apply mortar by squeezing the material from the mortar

bag into the joint lines. If fi lling a vertical line, start from

the top and work down. Apply slowly. Mixture should be

fl ush or higher than the refractory surface.

• Mix more material as necessary to fi nish the job and then

let the unit set until fi rm, may take two hours or more.

• Thoroughly clean the bag, tools and mixing bucket.

• Use a joint striker and strike the material in the joints. The

excess material should fall off somewhat dry.

• Sweep the loose material off the fl oor of the unit.

• Final cleanup with soap and water

• VERY IMPORTANT: Allow the mortar 72 hours to cure

before operating the fi replace.

Figure 11.4 Install Screens

Rod Screen

Clip

Inside

Firebox

Top of Fireplace

The mortar material provided should be suffi cient to com-

plete the installation of the molded brick panels without

considerable waste.

Note: We recommend mortar be applied after

facing materials are installed.

NOTICE: Do not stubstitute for HHT mortar. Other materials

may stain the molded brick panels.

Heat & Glo • RUTHERFORD-50 • 4059-333 Rev D • 07/08

О

О

О